Multifunctional bristle size separator

A scale machine and multi-functional technology, applied in the field of bristle scale machine, can solve the problems of large labor, high automation or degree, low production efficiency, etc., and achieve a clean production environment, high degree of automation, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

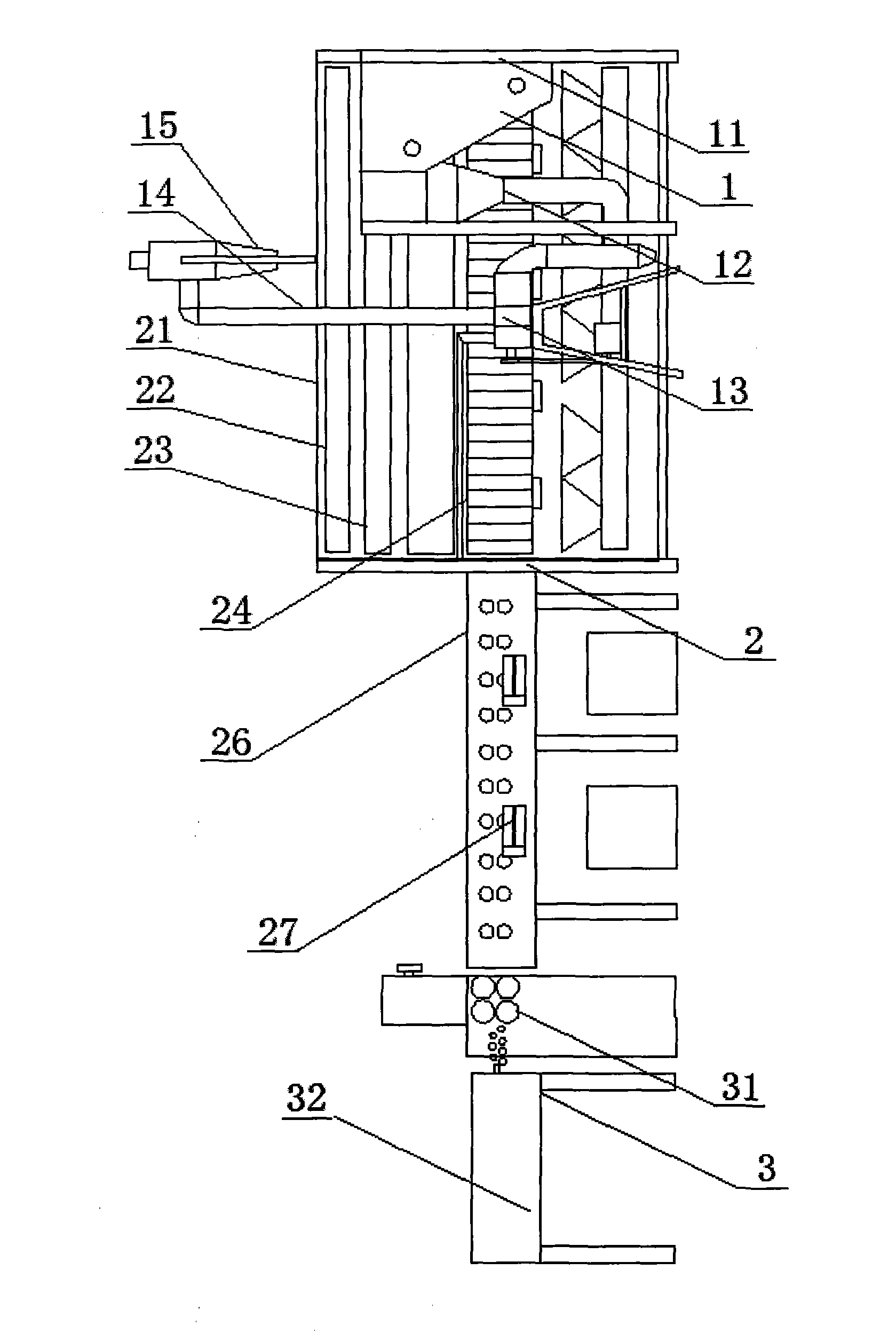

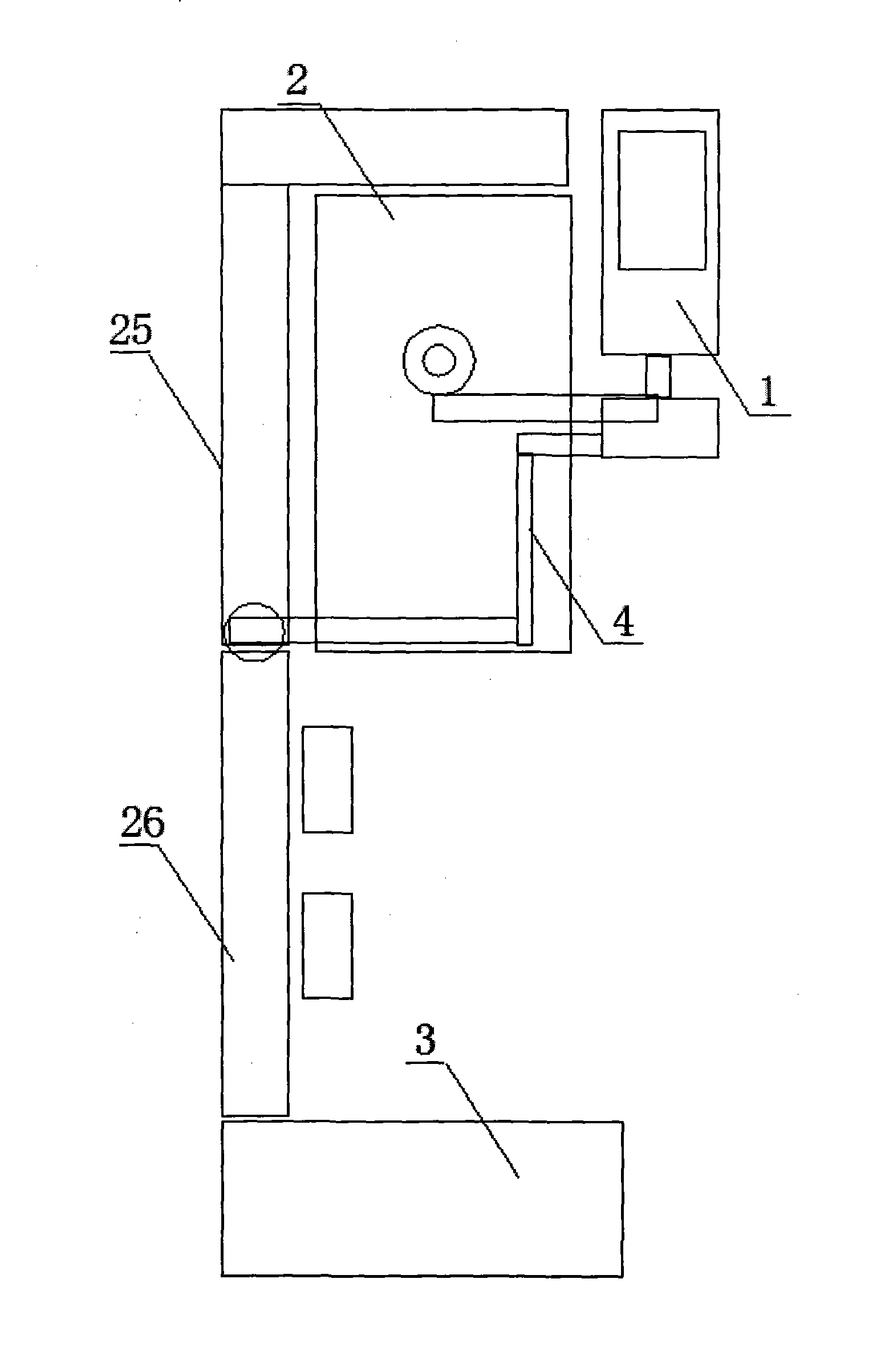

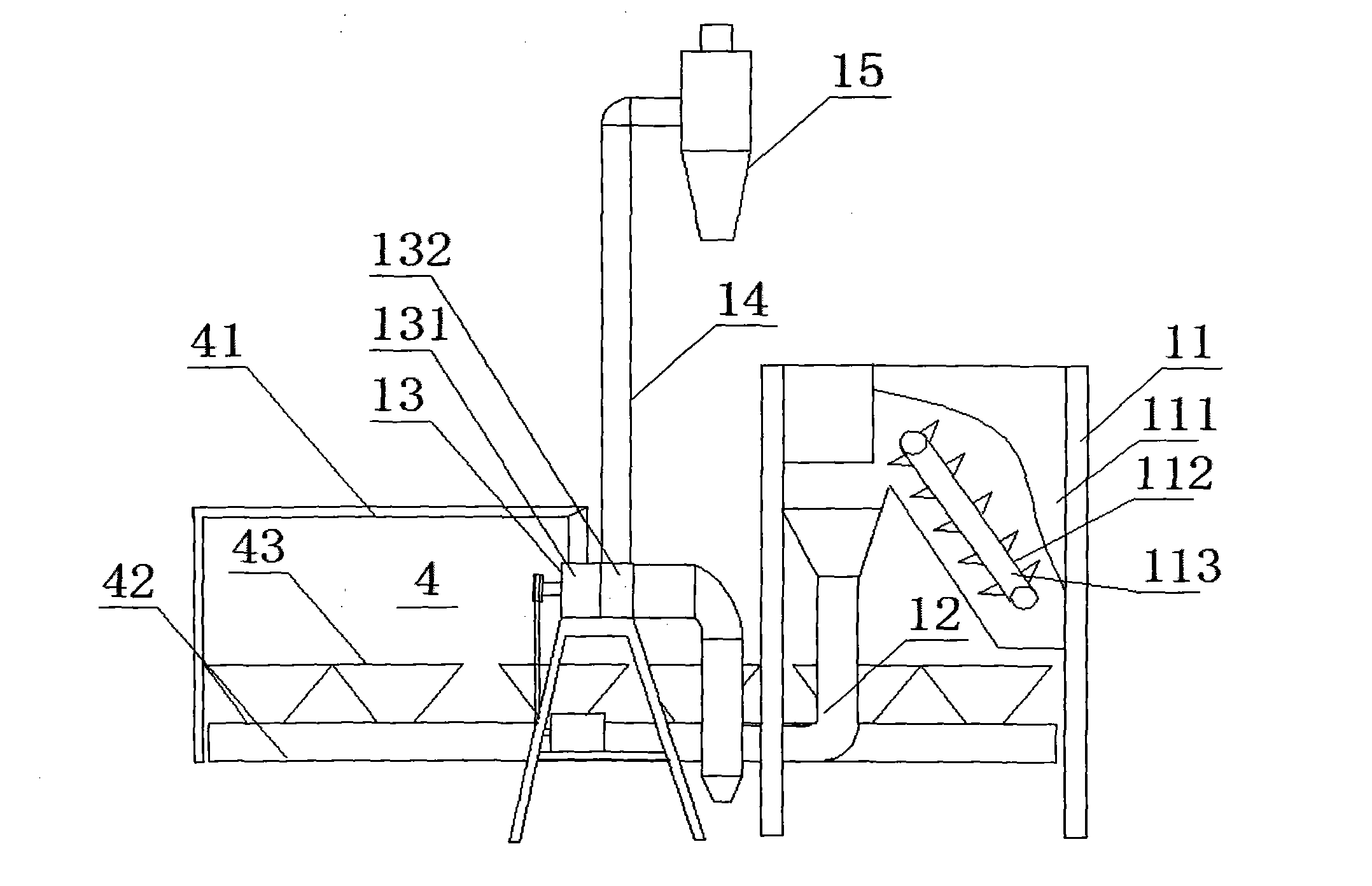

[0020] like figure 1 , 2 , a kind of multifunctional bristle ruler ruler shown in 3, 4, comprises the feeding device 1 that connects successively, ruler device 2 and row handle device 3, and described feeding device 1 comprises the feeding rack 11 that connects successively, Wind tunnel pipe 12, transmission fan 13, discharge pipe 14, discharge head 15, described ruler device 2 includes ruler frame 21, vibrating screen 22, transmission belt 23, hair feeding mechanism 24, transmission mechanism 25, ruler Mechanism 26, ruler roller 27, described vibrating screen 22, transmission belt 23, hair-feeding mechanism 24 layerings are installed on the ruler frame 21 successively, ruler mechanism 26 connects hair-feeding mechanism 24 by transmission mechanism 25, ruler roller 27 is installed on the ruler mechanism 26; the row device 3 includes a clip feeding mechanism 31 and a row mechanism 32 connected in sequence.

[0021] Further, a hair-returning mechanism 4 is also installed betwe...

Embodiment 2

[0029] Because most of the products do not have special requirements on size, the ruler mechanism 26 in embodiment 1 can not be used, therefore, the clip feeding mechanism 31 in the handlebar device 3 designed by the present invention can be directly connected to the transmission mechanism 25, realizing freedom The combination fully meets the needs of customers for different products in home production and improves production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com