Replacement method of coupling between reducer and hydraulic coupler of stacker

A technology of hydraulic coupler and replacement method, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of difficult disassembly and assembly, large volume and weight, increased maintenance time and maintenance cost of cantilever belt conveyors, etc. problems, to achieve the effect of reducing labor intensity, improving replacement efficiency, and reducing replacement steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0025] In the present invention, unless stated otherwise, the orientation words used such as "up, down, left, right" usually refer to the upper, lower, left, and right in the drawings, and "inner, outer" refers to Inside and outside relative to the outline of the part.

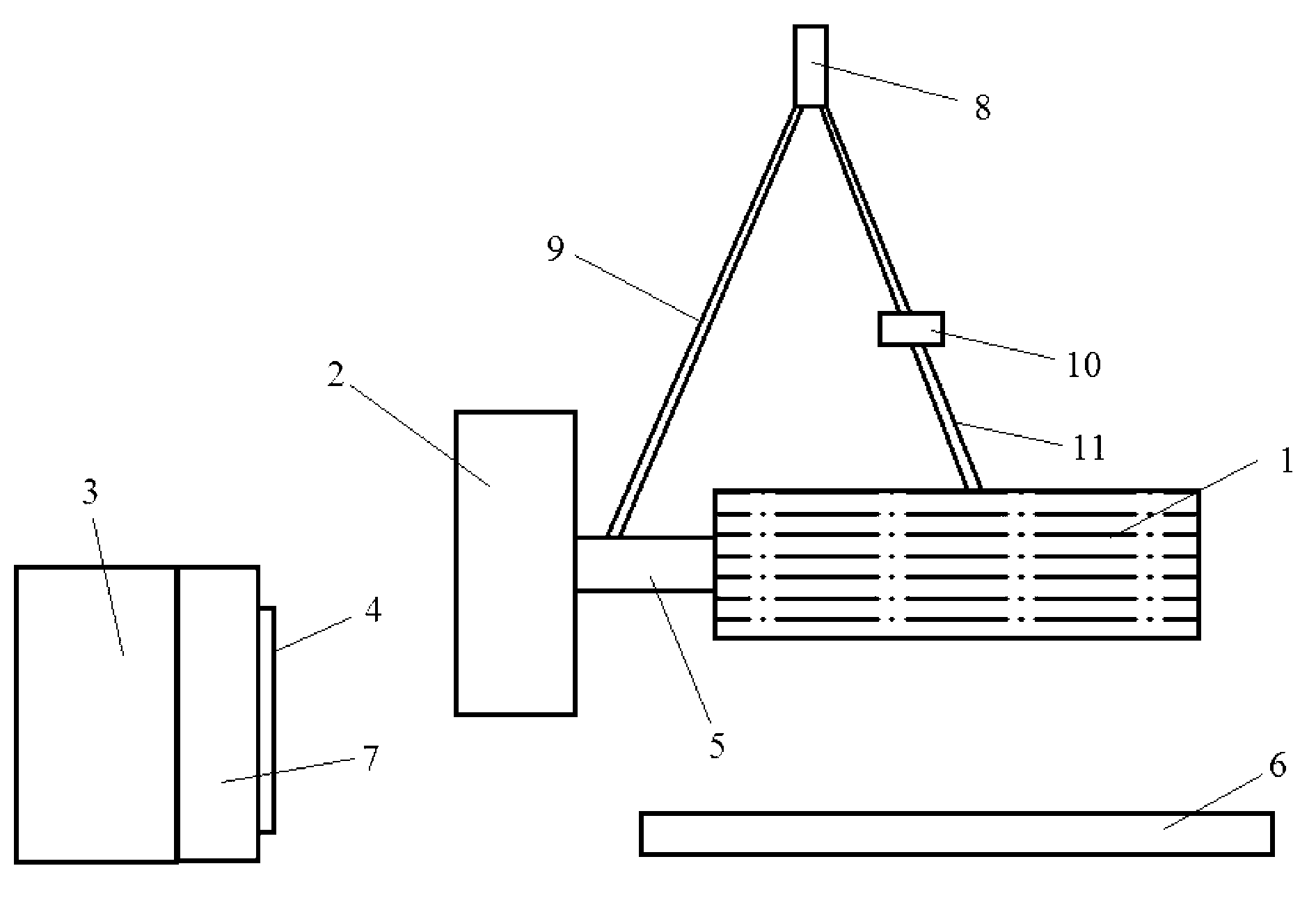

[0026] see figure 1 , in the cantilever belt conveyor of the stacker, the motor 1, the hydraulic coupler 2, and the reducer 3 are connected in sequence to transmit the power of the motor to the driving roller connected to the reducer 3 (for display). When the coupling 4 between the speed reducer 3 and the fluid coupling 2 is eccentric, the coupling 4 needs to be replaced. The invention relate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com