Technology for manufacturing hockey stick

A technology for making crafts and hockey sticks, which can be applied to other household appliances, household appliances, household components, etc., and can solve the problem of affecting production efficiency and product quality, the inability of the yarn material to be tightly wrapped in the heat-resistant film tube, and the loss ratio of epoxy resin Instability and other problems, to achieve the effect of improving operation efficiency and product quality, low production cost, and improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

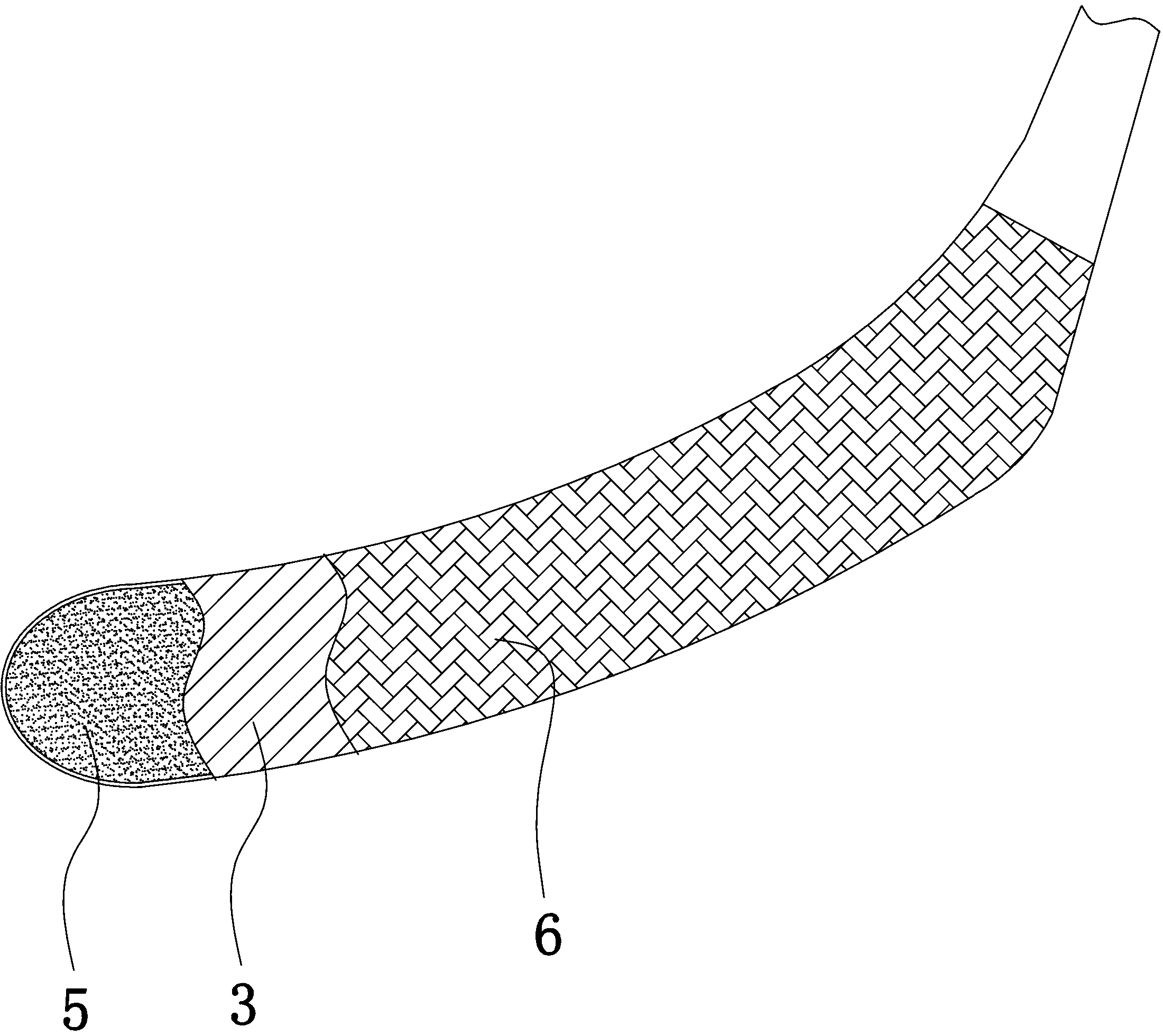

[0043] A hockey stick manufacturing process, including a rod rough blank manufacturing process and a strike plate rough blank manufacturing process;

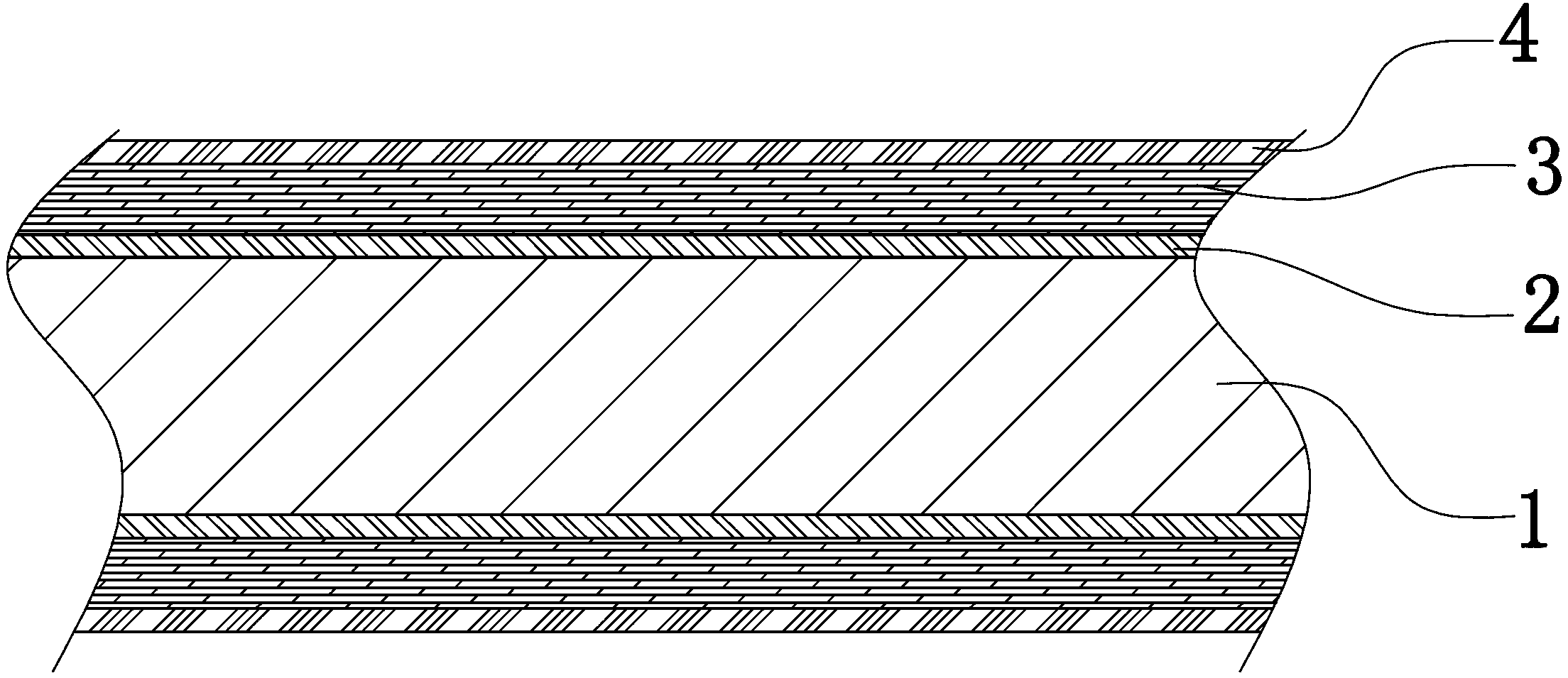

[0044] The manufacturing process of the above-mentioned pole rough blank comprises the following steps successively: as figure 1 as shown,

[0045] A1: Set the heat-resistant film tube 2 on the bead 1, and then insert the vacuum air pipe into the opening end of the heat-resistant film tube sleeve, and vacuumize to make the heat-resistant film tube close to the surface of the bead.

[0046] B1: The yarn material sheet 3 is arranged in an orderly manner and wound on a bead lined with a heat-resistant film tube. The yarn material sheet is a yarn material sheet attached with epoxy resin.

[0047] B1.1: Roll a layer of glass fiber woven cloth 4 outside the yarn material. The glass fiber woven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com