Method for setting novel fastener type steel pipe external scaffold wall connection piece

A technology for external scaffolding and wall parts, which is applied to the accessories of scaffolding, building structure support, building structure support, etc. It can solve the problems of scrapped anchor bolts, hidden safety hazards in demolition, and high construction requirements, so as to achieve accurate buried positions and improve construction efficiency. , the effect of no hidden danger of water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

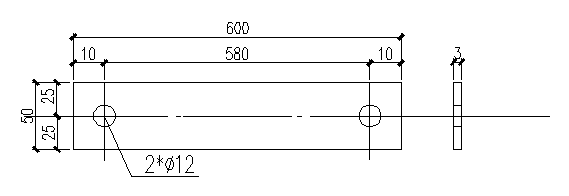

[0018] From figure 1 It can be seen that the rigid wall connecting piece of the present invention can be made of flat iron or flat steel with a length of 600mm, a width of 50mm, and a thickness of 3mm, and a round hole with a diameter of 12mm is drilled at a distance of 10mm from the end, and both ends can be drilled. hole, or just drill one end.

[0019] The present invention can choose flat steel or flat iron of material Q235, and the specification is 600*50*3mm; first, one end of the flat iron is folded into an L shape and embedded in the beam and plate of the main structure in advance, and the flat iron or The flat steel is bound or welded to the steel bars in the beam and plate; then the other end of the flat iron or flat steel with a diameter of 12mm round hole drilled in advance is fastened with the fastener bolts and then fastened with a horizontal short steel pipe to the vertical pole. After the concrete pouring is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com