Boiling heat exchange cooling device for hydrodynamic retarder

A technology of hydraulic retarder and boiling heat exchange, applied in the direction of hydraulic resistance brake, slack adjuster, brake type, etc., can solve the problems such as limited space for cooling capacity improvement, large temperature fluctuation of transmission fluid, lag in cooling effect, etc. Achieve the effect of smaller axial size, better cooling effect and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

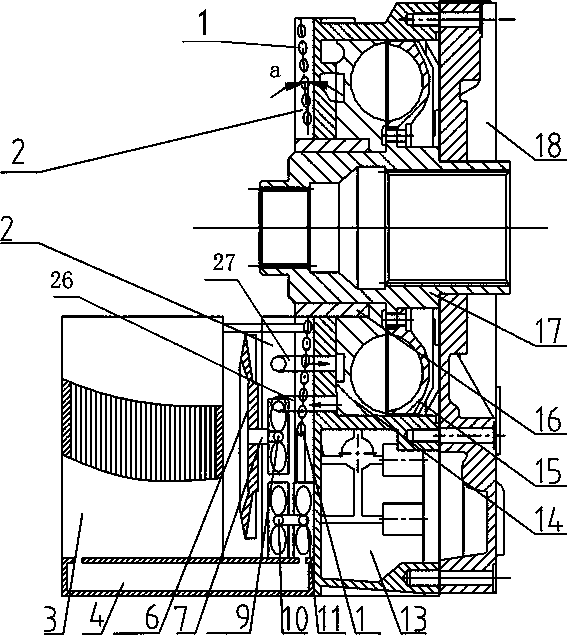

[0020] see figure 1 , the hydraulic retarder includes a hydraulic retarder box 13, the hydraulic retarder box 13 is provided with a hydraulic retarder box cover 18, and a hydraulic retarder is built in the hydraulic retarder box 13 Speed gear fixed wheel 14, hydraulic retarder moving wheel 15, axle sleeve 16 and axle 17.

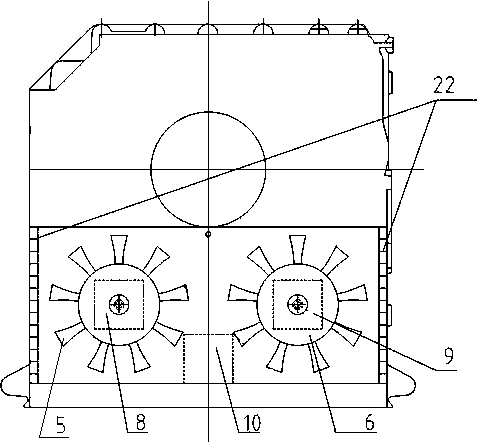

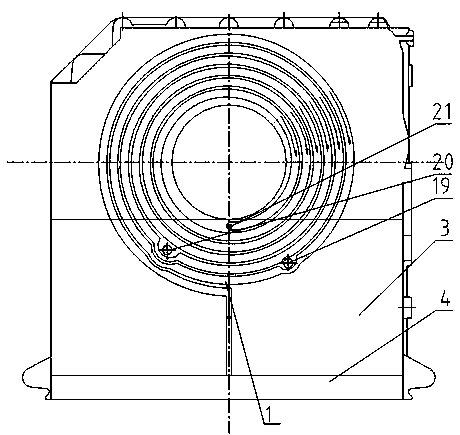

[0021] see Figure 1-Figure 4 , a boiling heat exchange cooling device for a hydraulic retarder, which includes a water tank 4, a condenser 3 and an interlayer 2 arranged on the outer wall of the fixed wheel of the hydraulic retarder, and the interlayer 2 is provided with an oil flow channel and A spiral cooling channel 1, the inlet of the cooling channel 1 is connected to the outlet of the water tank 4 through the water pump 11, the outlet 21 of the cooling channel is connected to the inlet of the condenser 3, and the outlet of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com