Secondary side water supplementing device for closed heat exchange system

A technology of heat exchange system and water replenishment device, which is applied in the direction of heating system, heating and ventilation control system, heating and ventilation safety system, etc. Small energy consumption, large amount of gasification, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

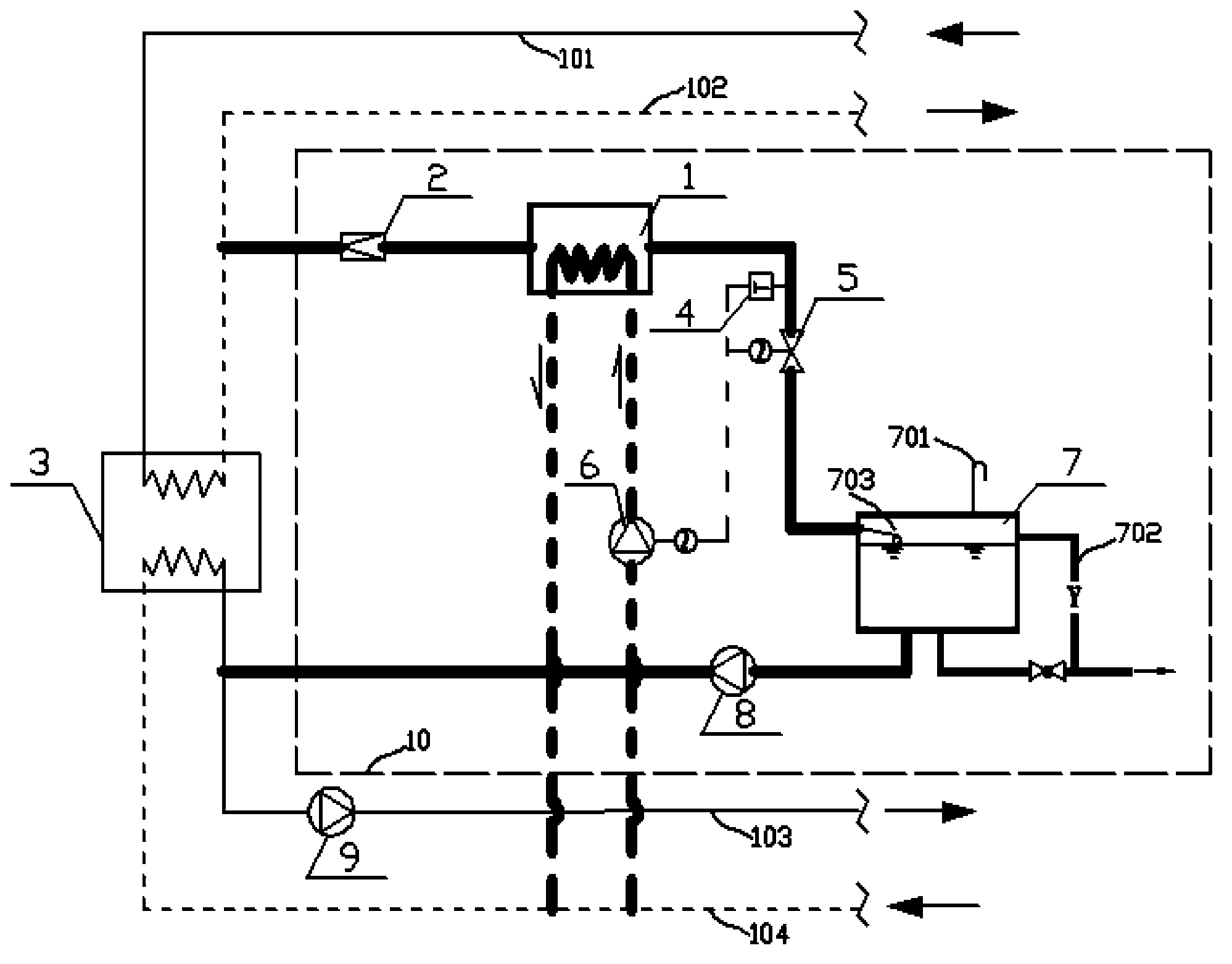

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0029] see figure 1 , the closed heat exchange system uses the secondary side water supply device, including: a heat exchanger 3, a primary network water supply pipe 101 connected to the heat exchanger 3, a primary network return water pipe 102, a secondary network water supply pipe 103 and a secondary network return pipe 104,

[0030] The primary network return pipe 102 is also connected to a pre-heat exchanger 1, and the secondary network return pipe 104 is also connected to the pre-heat exchanger 1 through the preheat pump 6, and part of the primary network return water pretreated by the pre-heat exchanger 1 into tank 7,

[0031] A water tank 7 is connected to the water supply pipe of the secondary network through the replenishment pipe 10 for the part of the return water of the primary network that meets the requirements.

[0032] In a preferred embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com