Multi-axis low-rotating-speed spiral rotor in heat exchange tube

A technology of heat exchange tubes and low rotation speed, which is applied in the direction of cleaning of rotating equipment, heat transfer modification, heat exchange equipment, etc., and can solve problems such as fluid increase, heat transfer performance decline, enhanced heat transfer, and limitation of scale prevention and descaling capabilities , to achieve the effect of increasing the tangential velocity and radial velocity, improving the ability of heat transfer enhancement, and enhancing the ability of removing dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

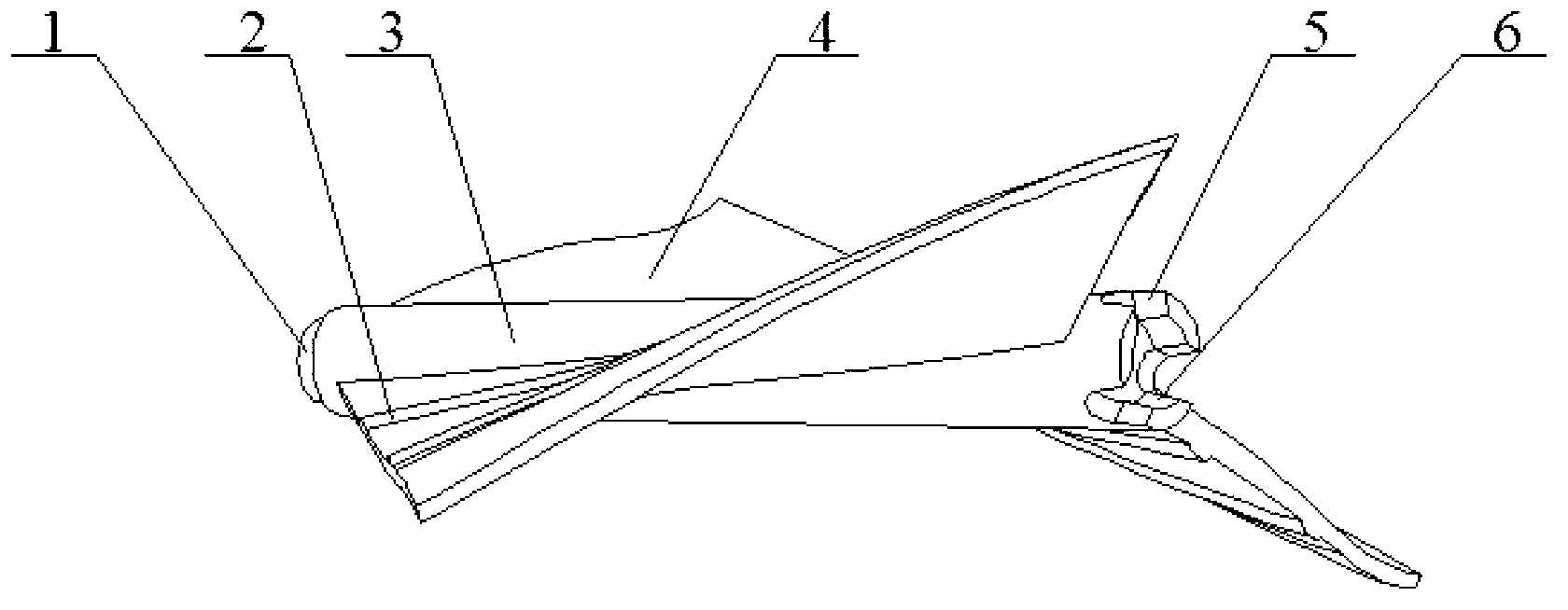

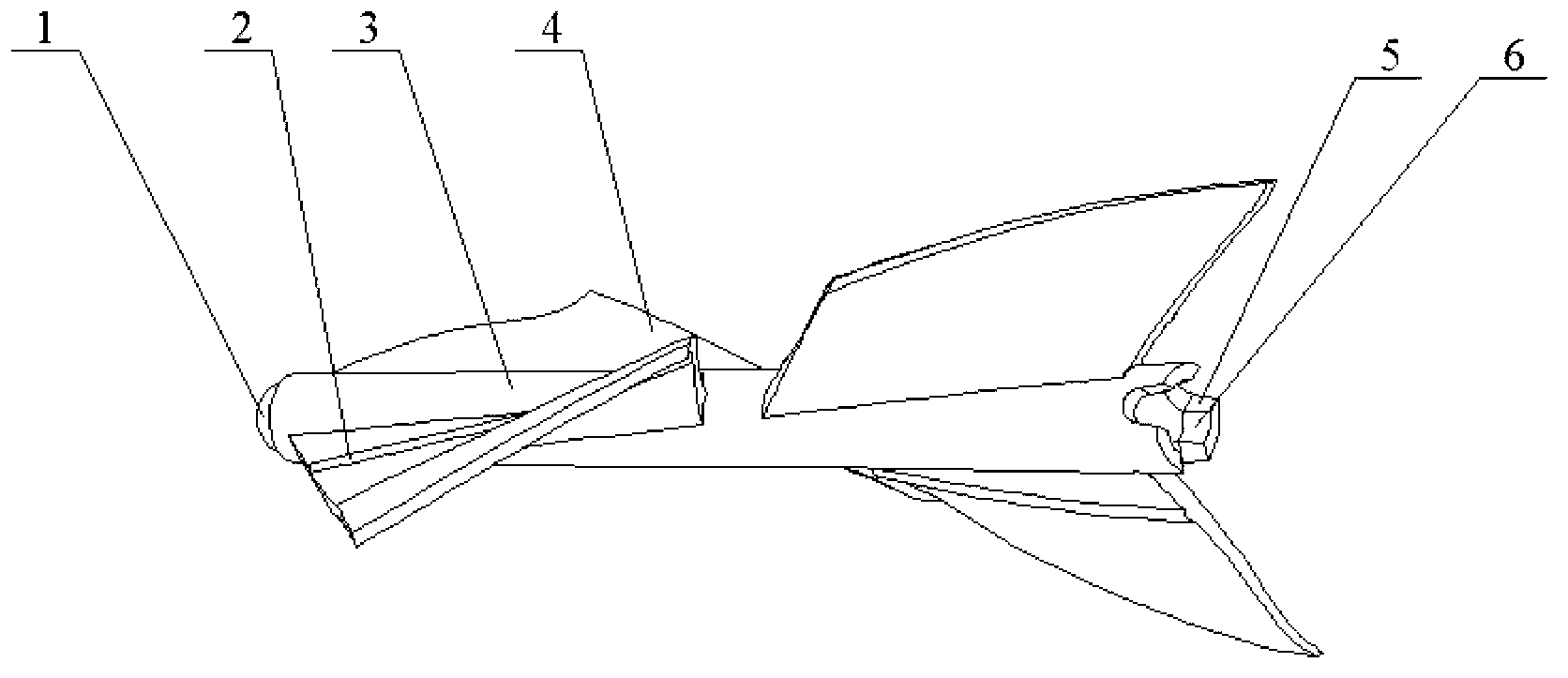

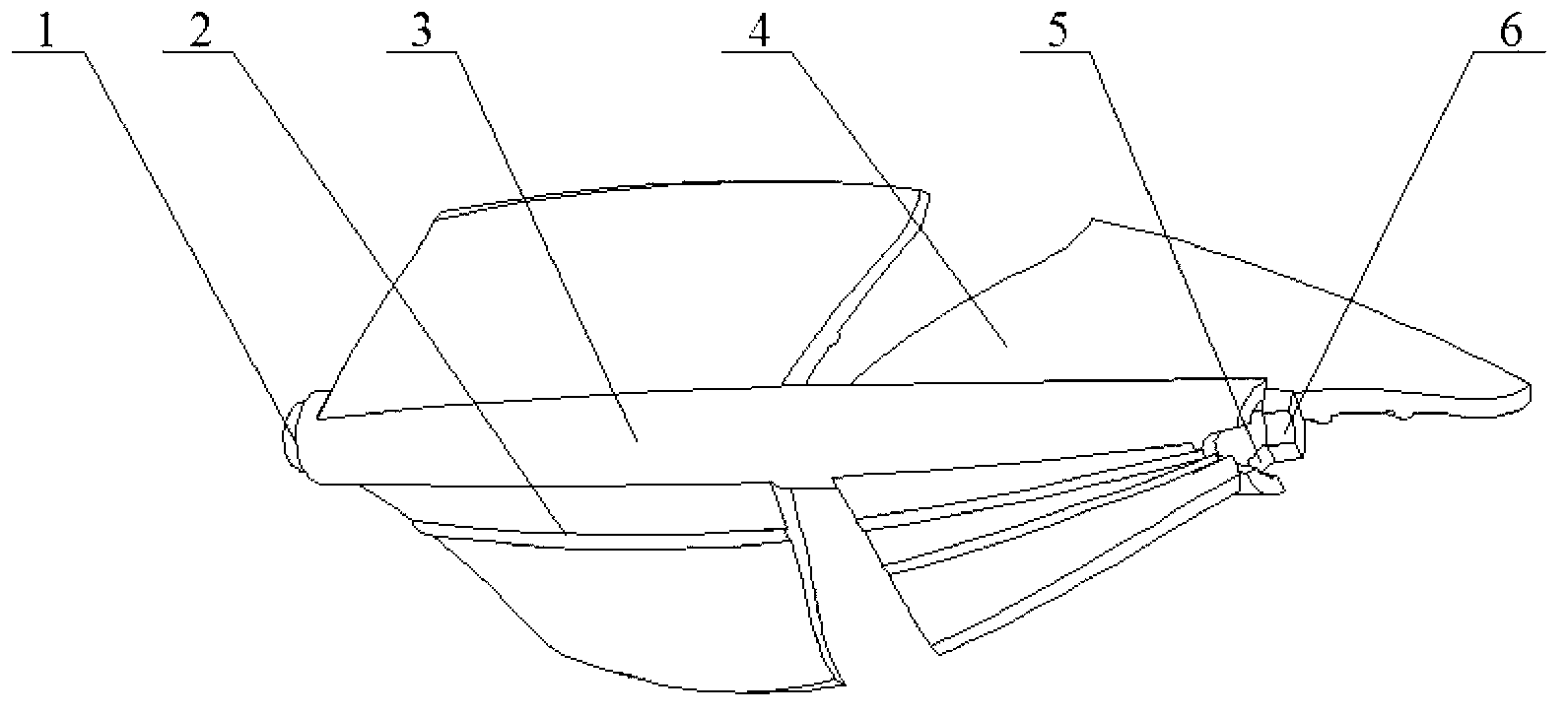

[0023] Such as Figure 8 As shown, the present invention relates to an implementation method of a multi-axis low-speed helical rotor in a heat exchange tube. The enhanced heat transfer device includes a rotor, a rotating shaft 7, a heat exchange tube 8 and a pendant 9. Several rotors are connected in series through the rotating shaft 7. Together, the pendant 9 is fixed on both ends of the heat exchange tube 8, and the two ends of the rotating shaft 7 are respectively fixed on the pendant 9. The rotor of the present invention is composed of a certain number of multi-axis helical blades 4 fixed on the surface of the hollow shaft 3. The hollow The shaft 3 also has a ball socket boss 1, a ball socket concave table 6 and a hole 5 communicating with the inner hole of the hollow shaft 3. Among two adjacent rotors, the ball-socket boss 1 at the head of the hollow shaft 3 of one rotor is combined with the ball-socket recess 6 at the tail of the hollow shaft 3 of the other rotor so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com