Charging equalization control circuit of battery pack

A technology for controlling circuits and charging circuits, applied in battery circuit devices, circuit devices, current collectors, etc., can solve problems such as low specific capacity, inability to effectively maintain physical and chemical properties of lithium iron phosphate batteries, and reduced battery capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

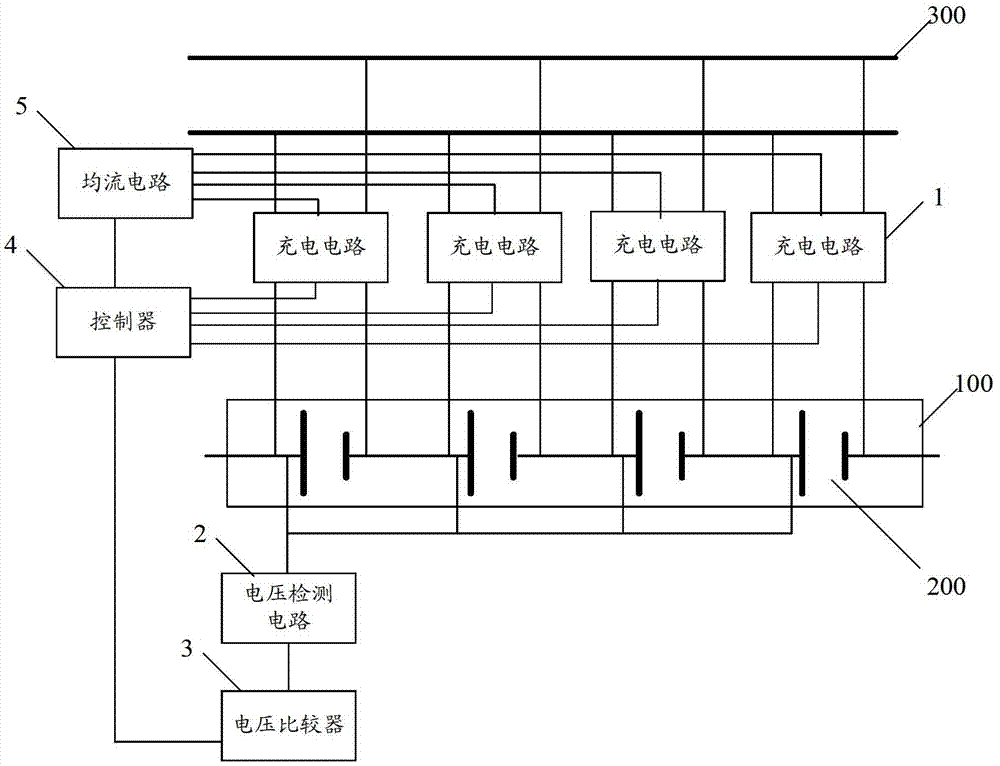

[0040] figure 1 It is a schematic structural diagram of a battery charge equalization control circuit provided in the embodiment of the present application.

[0041] The control circuit is used to control the charging process of the battery pack, so that the battery cells in the battery pack can achieve balanced charging, and for the battery pack, at least two battery cells are included. figure 1 Among them, 100 is a battery pack, 200 is a battery cell, and 300 is a power cord for charging the battery pack.

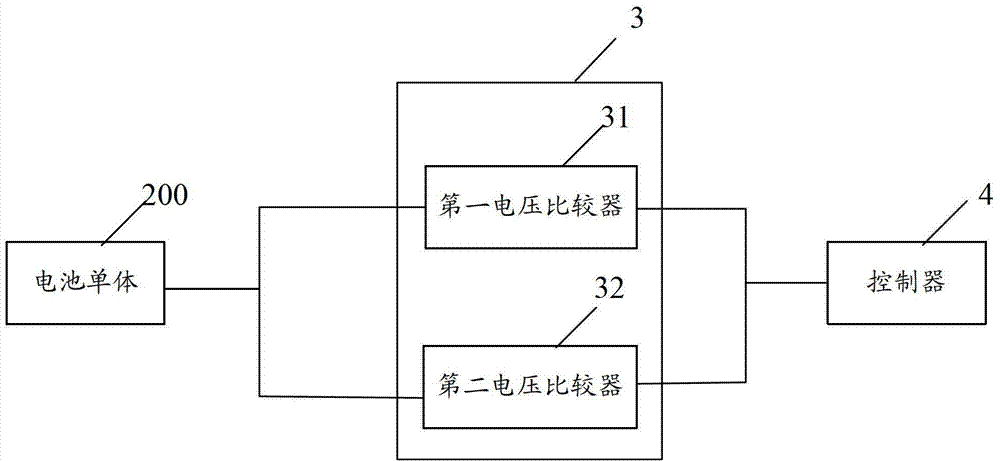

[0042] Such as figure 1 As shown, the control circuit includes: including: a charging circuit 1 , a voltage detection circuit 2 , a voltage comparator 3 , a controller 4 and a current equalizing circuit 5 .

[0043] The input end of the charging circuit 1 is connected to the power line 300, and the output end of the charging circuit 1 is respectively connected to at least two of the battery cells 200. The function of the charging circuit 1 is to convert the voltage on t...

Embodiment 2

[0063] In order to avoid energy loss caused by frequent detection of the battery cell voltage, in other embodiments of the present application, the interval time of detection can also be set during the charging process of different modes.

[0064] Figure 4 A schematic structural diagram of another charging equalization control circuit for battery packs based on changing the charging mode provided by the embodiment of the present application.

[0065] Such as Figure 4 As shown, the charge equalization control circuit may further include: a delay controller 6, the delay controller 4 is connected with the voltage detection circuit 2, and is used to control the detection interval of the voltage detection circuit.

[0066] When the average voltage is less than the first preset voltage threshold and the charging current is between 0.1C and 0.2C, a first delay instruction is generated and sent to the voltage detection circuit to control the voltage detection circuit 2 to delay the...

Embodiment 3

[0072] In the first embodiment above, it is possible to adjust the charging condition of the battery cell with a faster charging speed, but after the adjustment is completed, the charging condition of the battery cell will tend to be normal. , will again cause this cell to charge slower than the other cells.

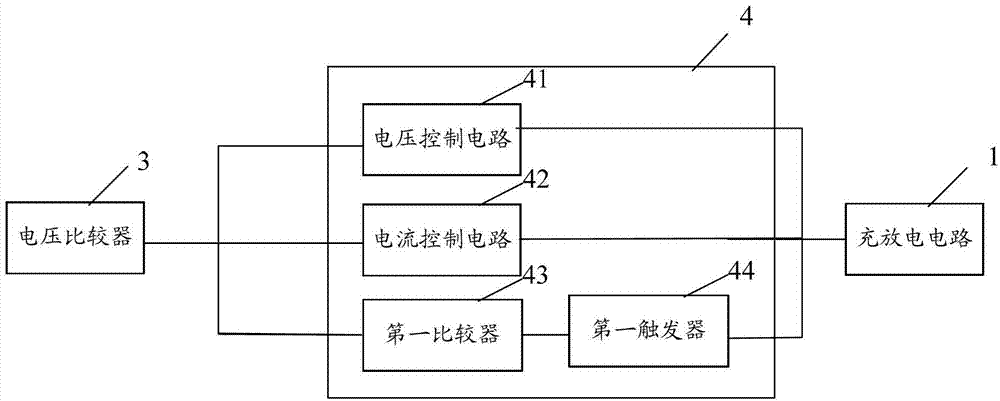

[0073] For this reason, in the embodiment of this application, such as Figure 5 As shown, the controller 3 in the control circuit may also include: a second comparator 45 and a second flip-flop 46, wherein:

[0074] The second comparator 45 is connected with the voltage comparator 3, and is used for judging whether the voltage difference of the battery cells in the battery pack is less than a preset threshold, where the preset threshold takes into account the difference between the cells The difference is set, that is, the small difference between the battery cells is allowed;

[0075] The second trigger 46 is connected with the second comparator 45, and is used to ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com