Bridgeless PFC converter working in Buck mode or Buck-Boost mode

A buck-boost and converter technology, applied in the direction of irreversible AC power input conversion to DC power output, no intermediate conversion to AC conversion equipment, sustainable manufacturing/processing, etc., can solve the limitation of power factor improvement, conversion Power density limitations of converters, converter heating and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

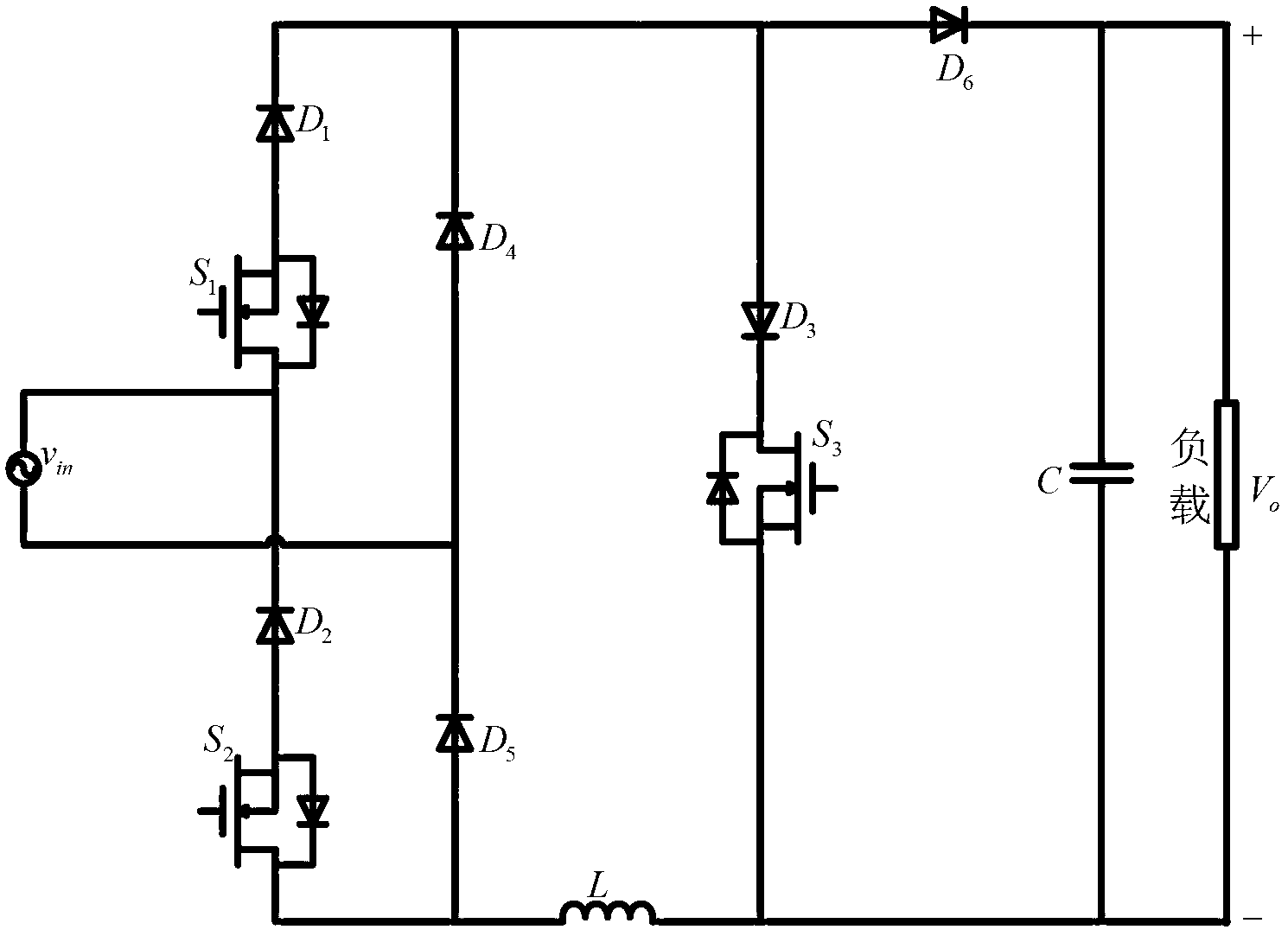

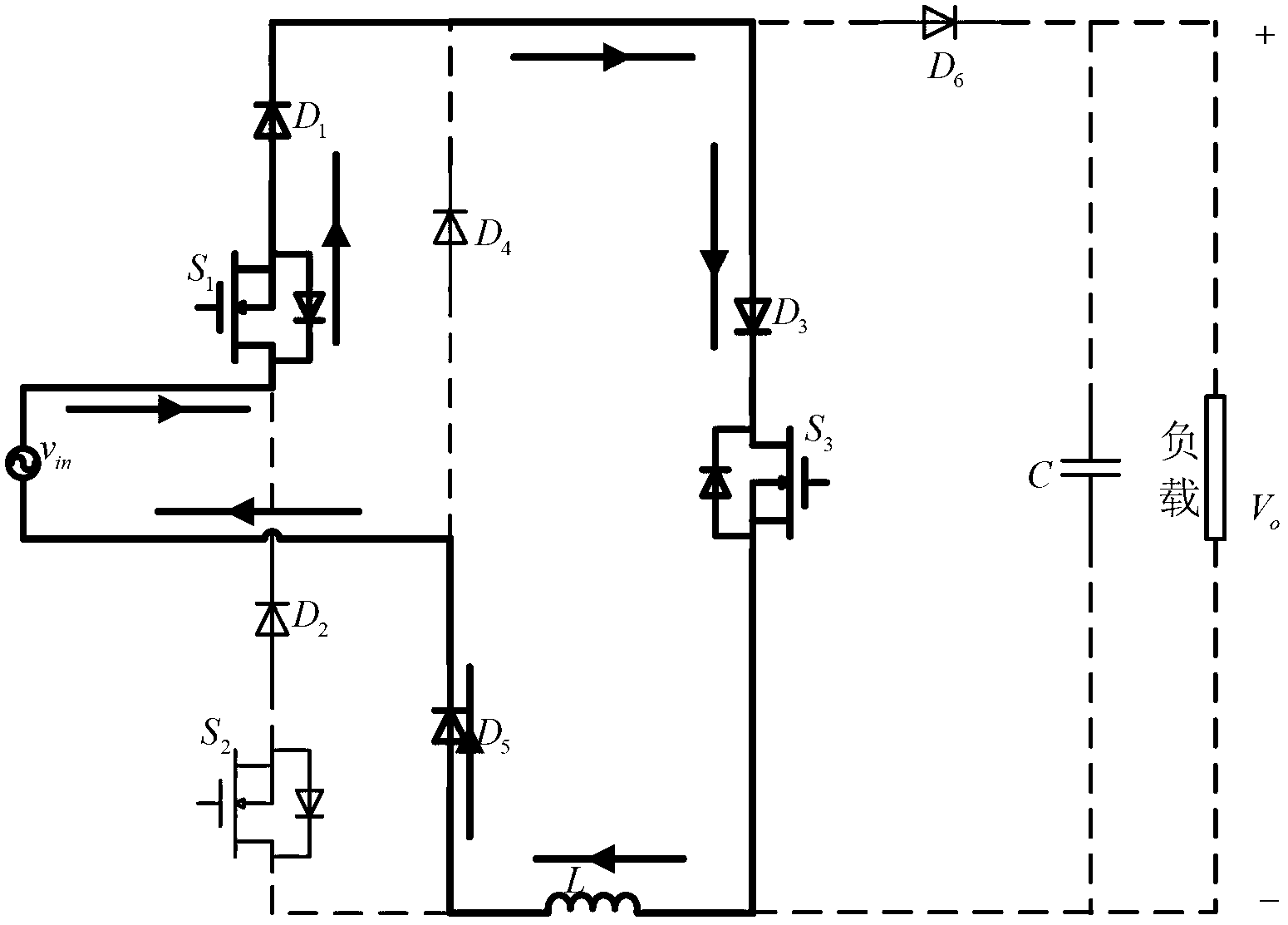

[0024] Such as figure 1 As shown, a bridgeless PFC converter for step-down and step-up switching, including a first switching tube S 1 , the second switch tube S 2 , the third switch tube S 3 , the first diode D 1 , the second diode D 2 , the third diode D 3 , the fourth diode D 4 , the fifth diode D 5 , the sixth diode D 6 , inductance L and capacitance C;

[0025] The first switch tube S 1 The drains are connected to one end of the input voltage, the second diode D 2 The cathode connection of the first switching tube S 1 source of the first diode D 1 the anode connection;

[0026] The first diode D 1 cathode of the fourth diode D 4 The cathode of the third diode D 3 The anode of the sixth diode D 6 the anode connection of the sixth diode D 6 The cathode of C is connected to one end of the capacitor C and the positive pole of the output voltage;

[0027] The other end of the capacitor C is respectively connected to the negative pole of the output voltage and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com