Tool tray for automobile electronic controller

A technology of automotive electronics and controllers, applied in the direction of manufacturing tools, workpiece clamping devices, assembly machines, etc., can solve problems such as dead zones and blind zones, achieve good economic benefits, and solve the effects of dead zones and blind zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

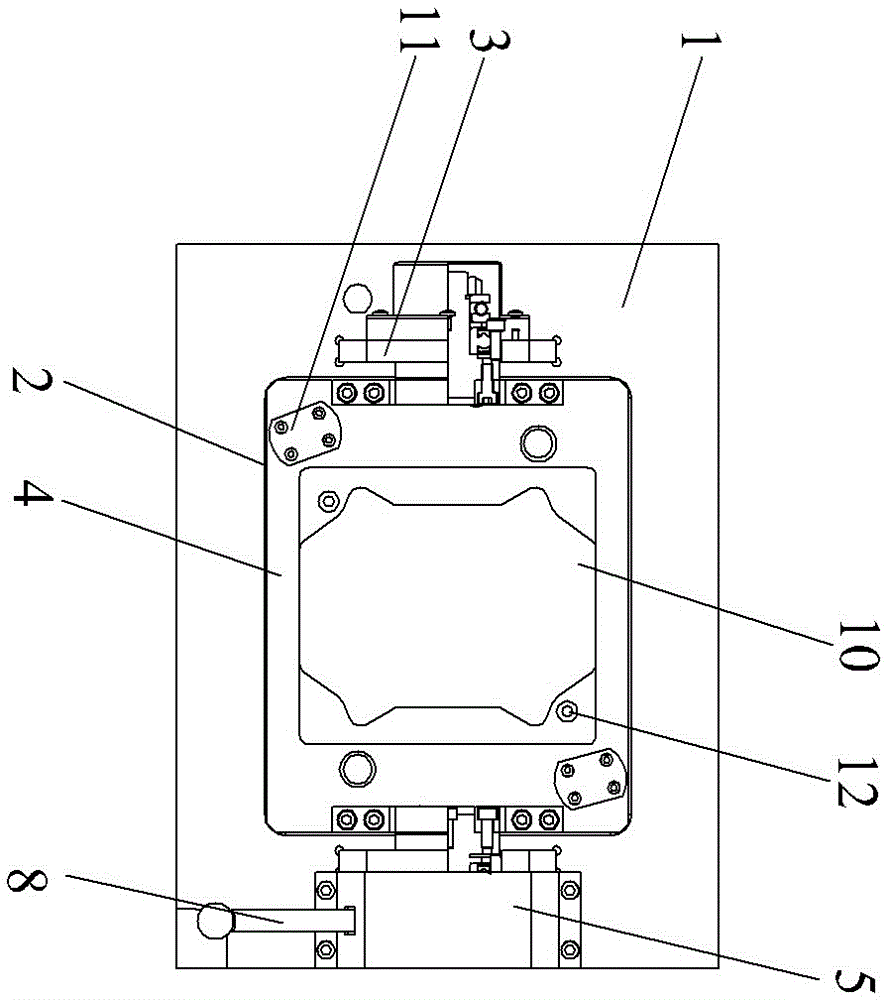

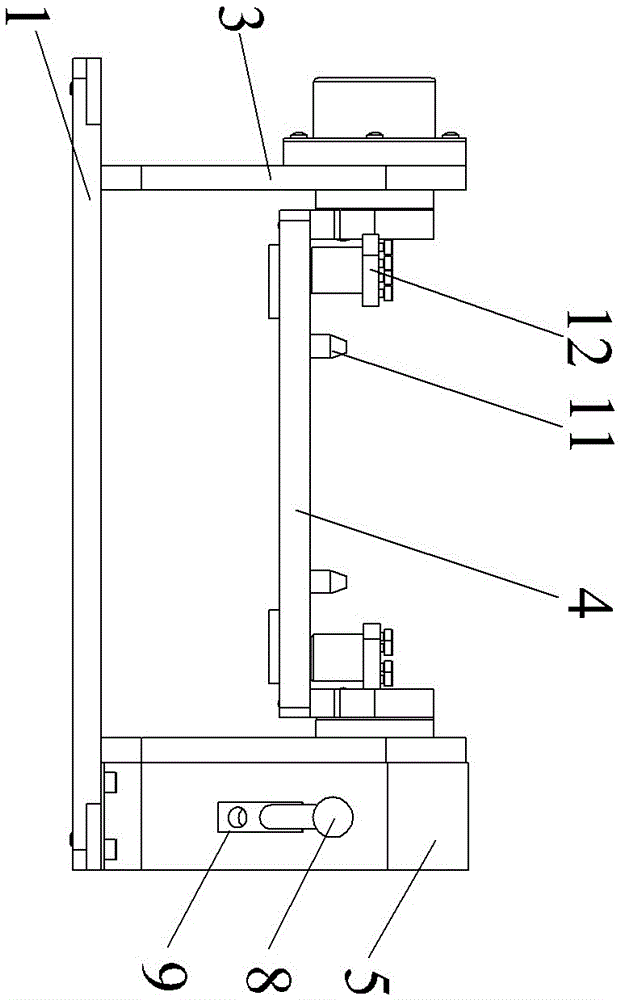

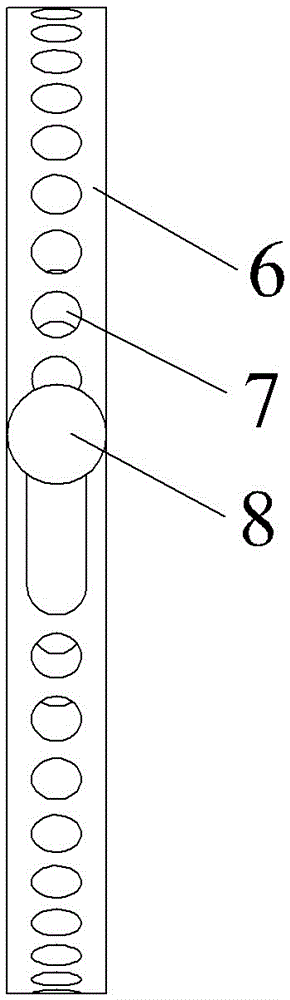

[0011] like figure 1 , figure 2 , image 3 As shown, the present invention comprises a base 1, the base 1 is provided with a through groove 2, and the base 1 at both ends of the through groove 2 is fixed with a support seat 3, and a turntable 4 is connected to the axis between the support seats 3, and the outer end of the support seat 3 A rotating device is fixed on the base 1, the rotating device includes a casing 5, a turntable 6 is arranged inside the casing 5, the turntable 6 is coaxially connected with the turntable 4, and through holes 7 are arranged at intervals on the outer circular surface of the turntable 6, and the latch 8 passes through the casing The opening groove 9 on the 5 is inserted in the through hole 7, and the through hole 7 is provided with 36, and is evenly arranged on the outer circular surface of the rotating disk 6, and the number of the through hole 7 can also be set according to the actual situation, then each A through hole 7 indicates that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com