Integrated narrow-frame photoelectric detector and manufacturing method thereof

A technology of photodetector and manufacturing method, which is applied in the direction of photometry, photometry, optical radiation measurement using electric radiation detector, etc. Thin and other problems, to achieve the effect of increasing the effective detection area, reducing the wall thickness, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

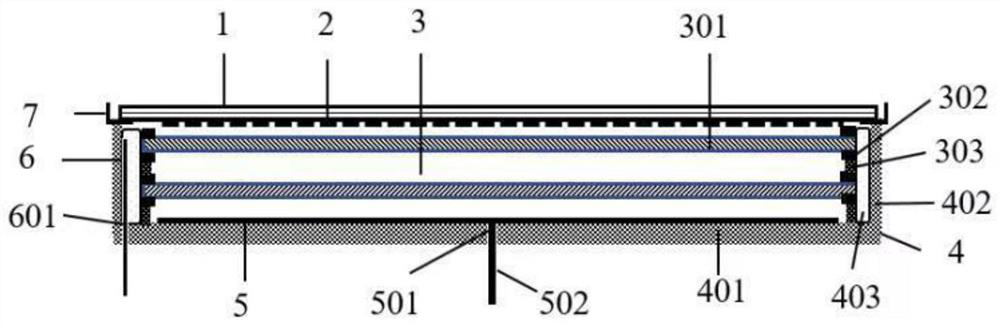

[0067] Such as figure 1 As shown, the integrated narrow-frame photodetector of the present invention includes a cathode window 1, a photocathode 2, a microchannel plate electron multiplier 3, an insulating shell 4, a charge collecting anode 5, an electrode lead 6 and an indium sealing groove 7 .

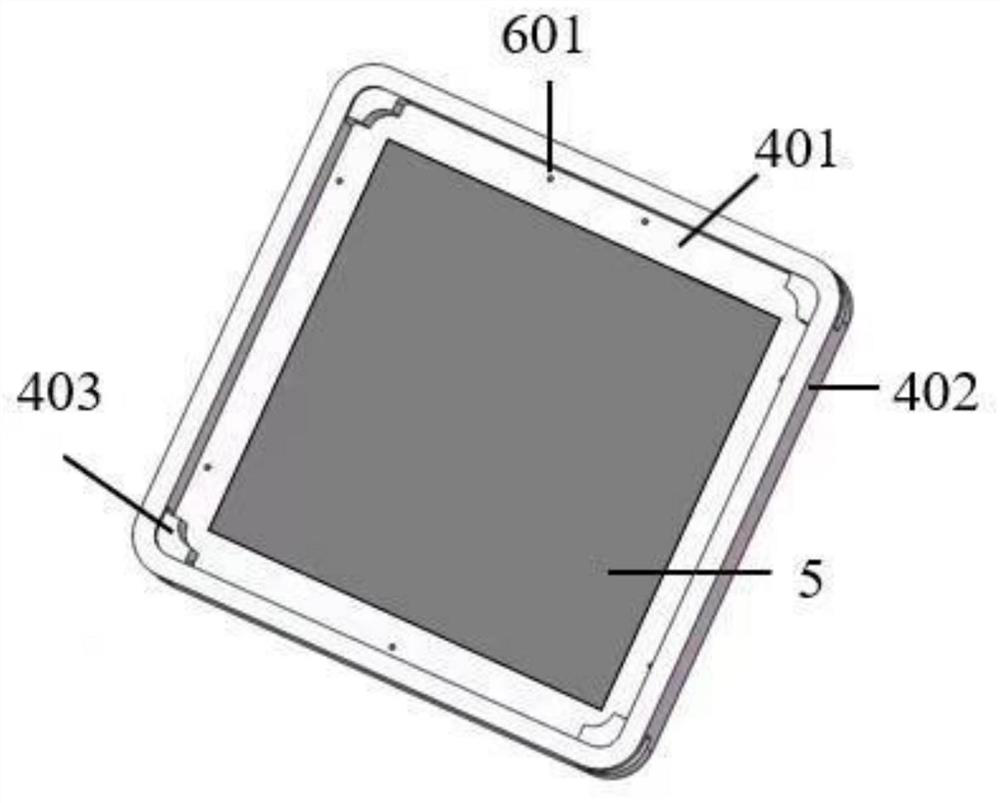

[0068] The insulating casing 4 of the present invention is groove-shaped composed of a bottom surface 401 and a side surface 402 , and can be an integral structure of a cylinder, a cuboid or a cube. The upper end surface of the side 402 of the insulating tube shell 4 is sealed with the cathode window 1 through the indium sealing groove 7 to form a vacuum sealed chamber; the electrode lead hole 601 and the anode pin hole 501 are arranged on the bottom surface 401; the card slot 403 is arranged on the insulating tube On the side 402 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com