Magnetostrictive actuator based switch flow control type microdroplet injection device

A magnetostrictive and flow control technology, applied in the direction of injection devices, liquid injection devices, etc., can solve the problem of the difficulty in precise control of the gas pressure pulse working time, the inability to work continuously for a long time, and the difficulty in controlling the accuracy and consistency of the sprayed droplet volume and other issues, to achieve a wide range of applicable materials, easy to work for a long time, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

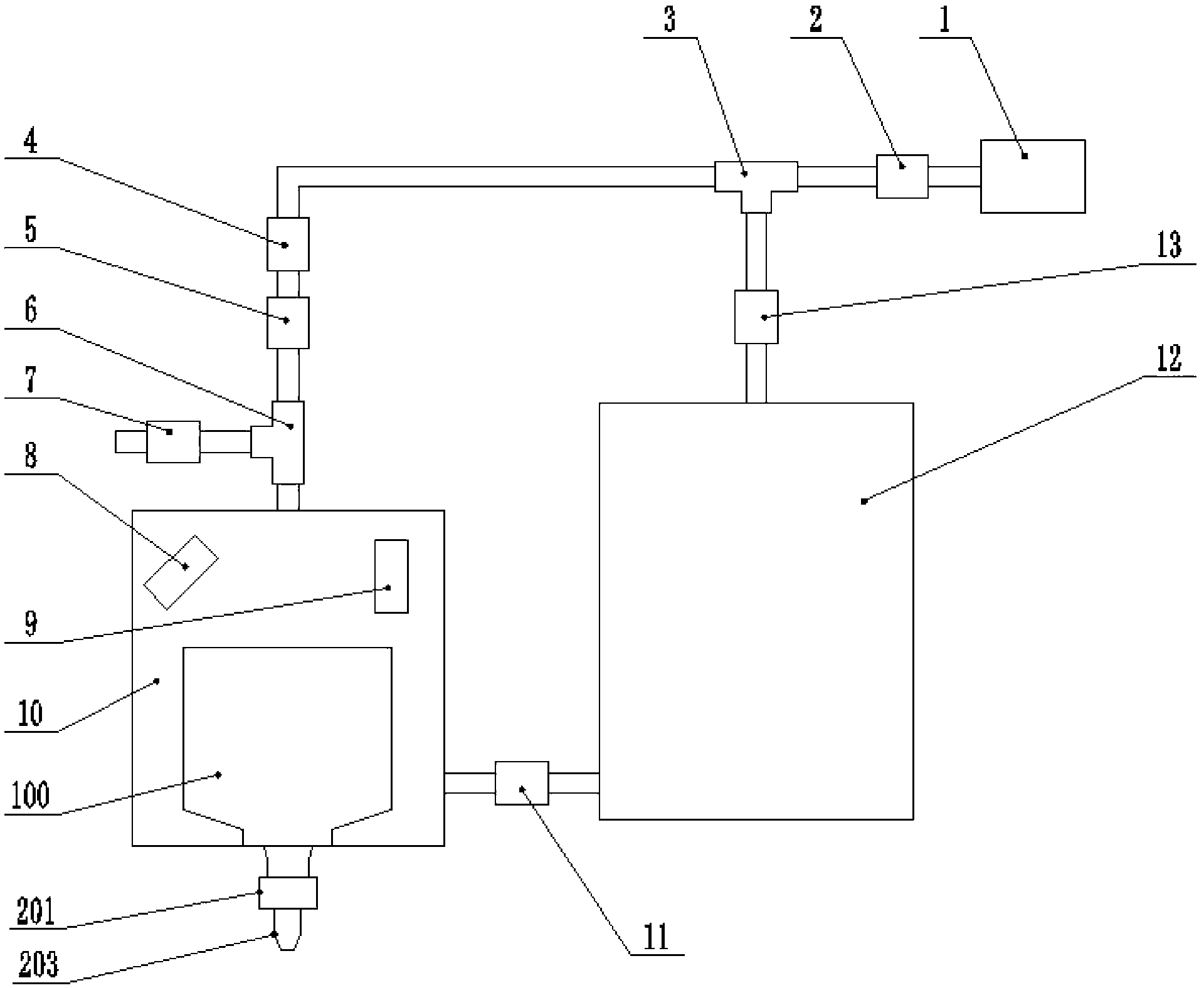

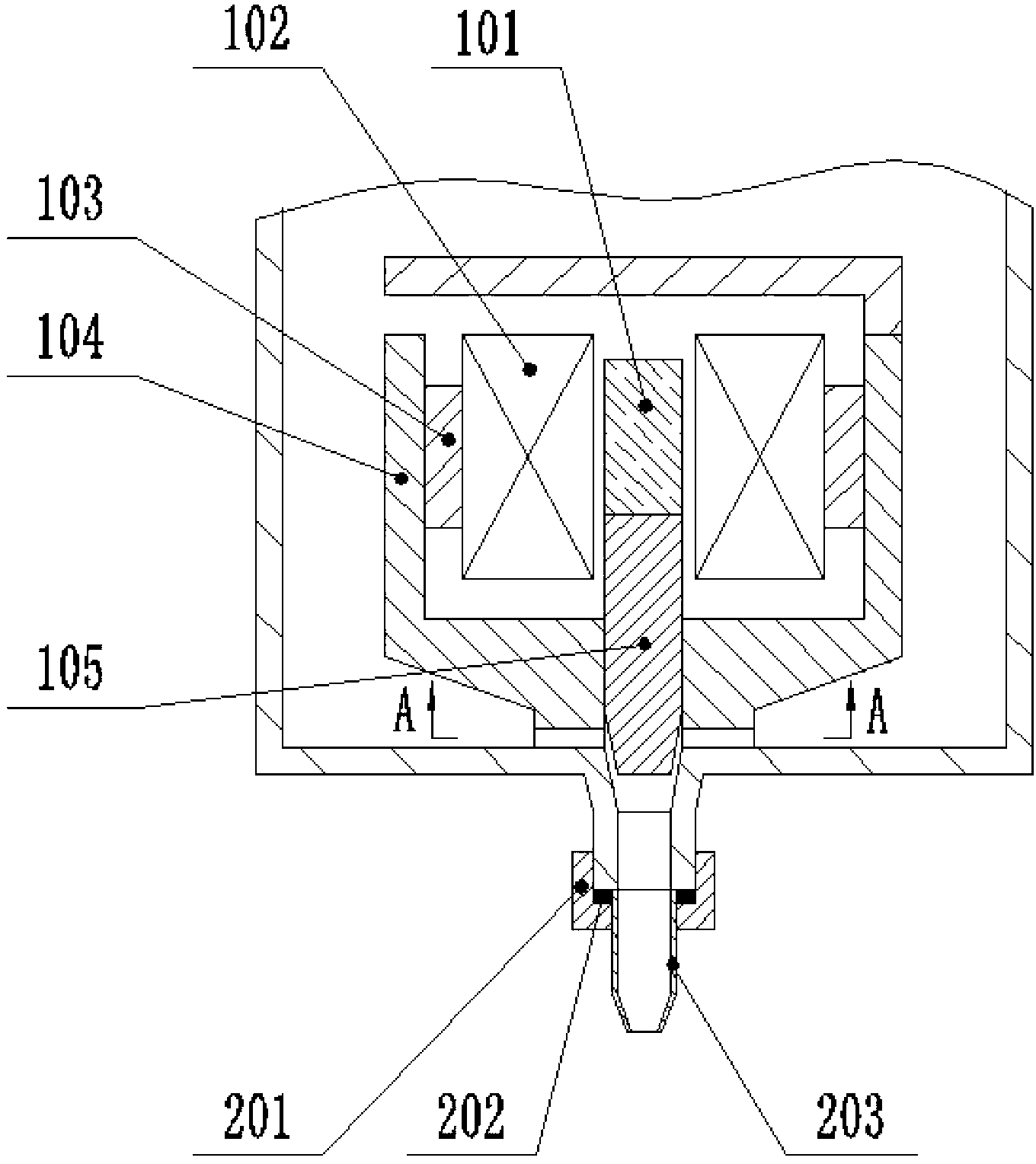

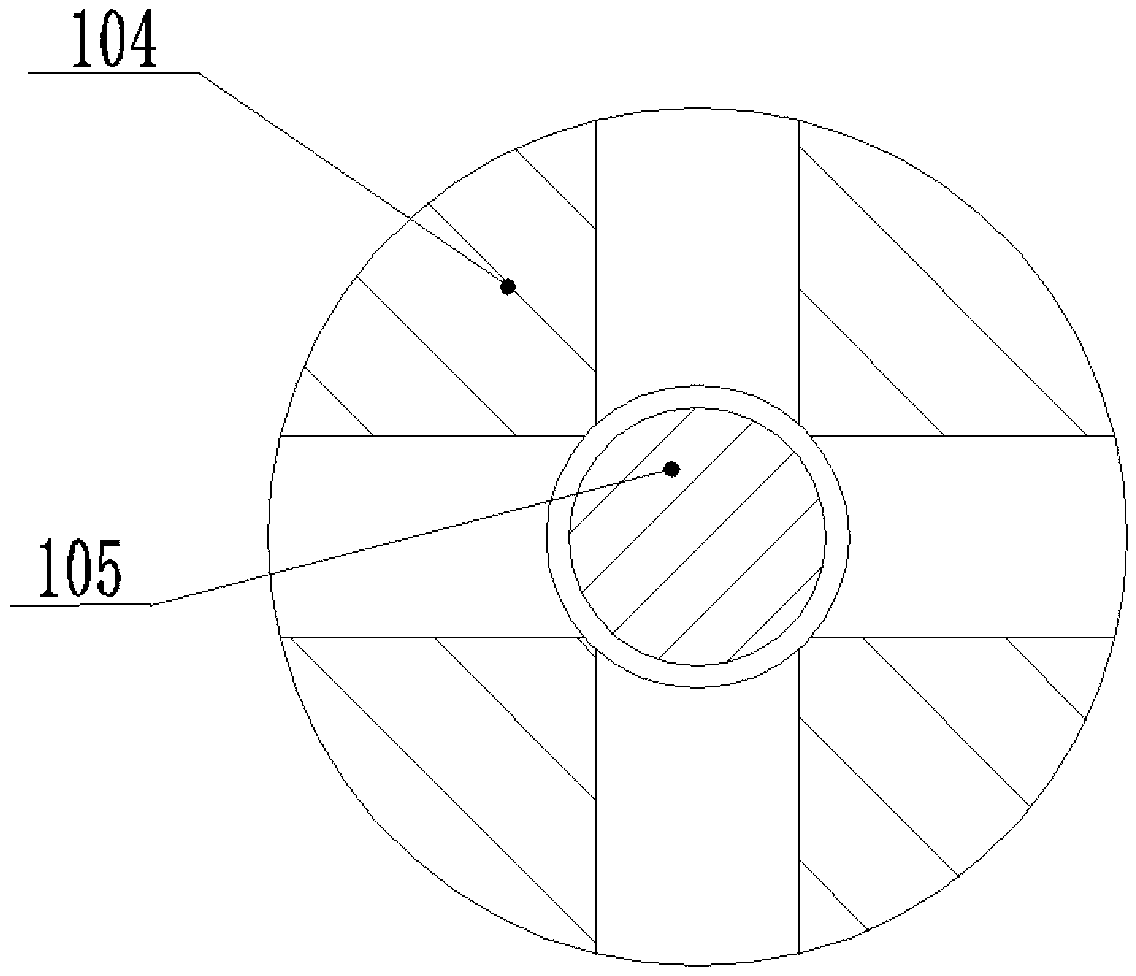

[0026] Such as figure 1 As shown, it is a switch flow control type droplet ejection device based on a magnetostrictive actuator, which includes a spray chamber 10 with a nozzle, a nozzle 203 connected to the nozzle of the spray chamber, a liquid storage tank 12 connected to the spray chamber 10, and a nozzle connected to the spray chamber 10. The chamber 10 and the liquid storage tank 12 are connected to the compressed gas supply module 1 and the control system. A flow control module 100 is arranged in the spray chamber 10 . The spray chamber 10 is cylindrical.

[0027] The outlet of the compressed gas supply module 1 is provided with a main pressure regulating valve 2, and the main pressure regulating valve 2 is controlled by the control system. The outlet of the main pressure regulating valve 2 is connected with a T-shaped joint 3, one end of the T-shaped joint 3 is connected with the outlet of the main pressure regulating valve 2, and the other two ends of the T-shaped jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com