Horizontal band sawing machine

A band saw machine, horizontal technology, used in band saws, sawing equipment, wood processing appliances and other directions, can solve the problems of not increasing the height of the gantry, the force of the lead screw is not balanced enough, and reducing the service life of the machine, etc. The effect of beam deformation, uniform weight distribution, and enhanced integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

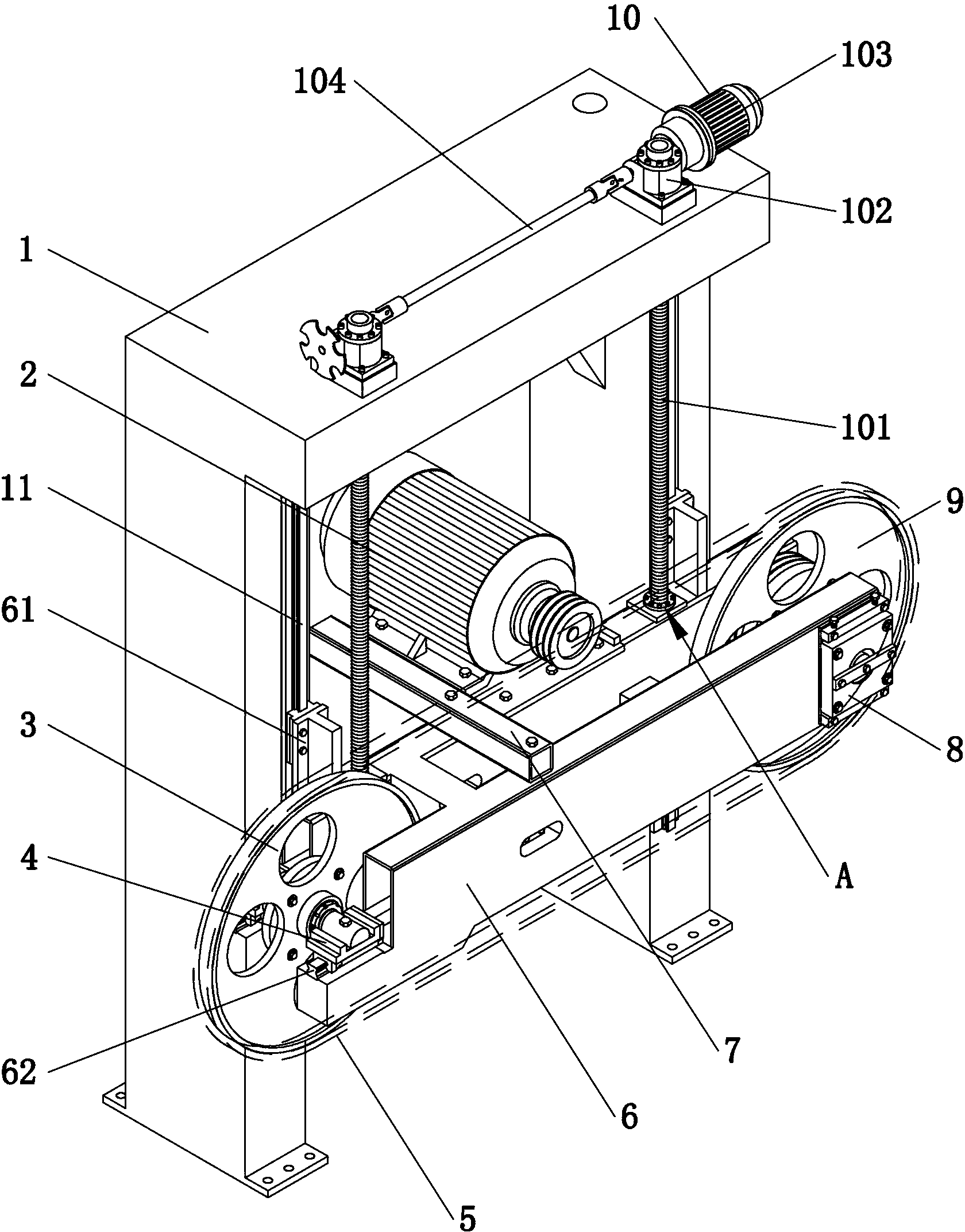

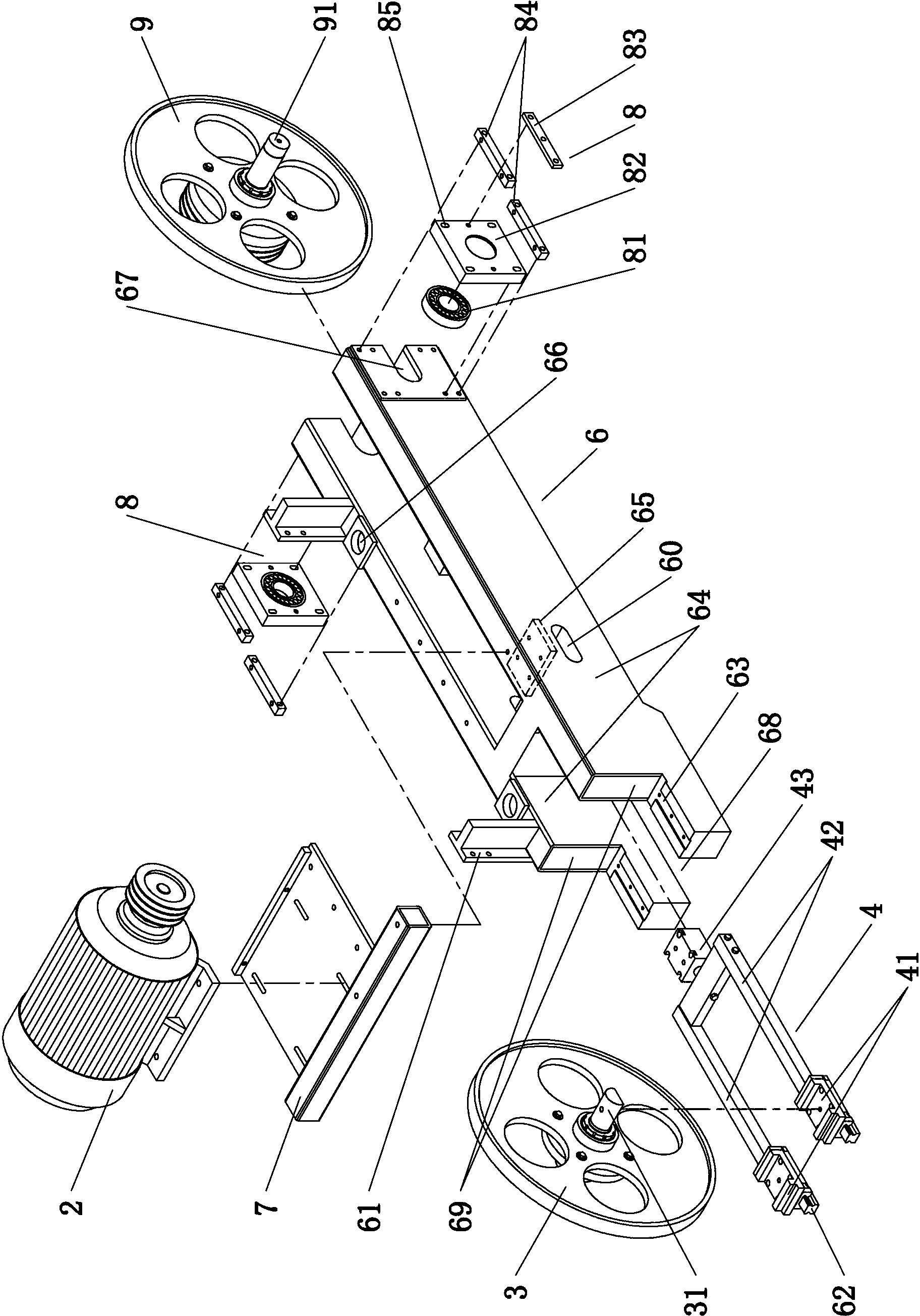

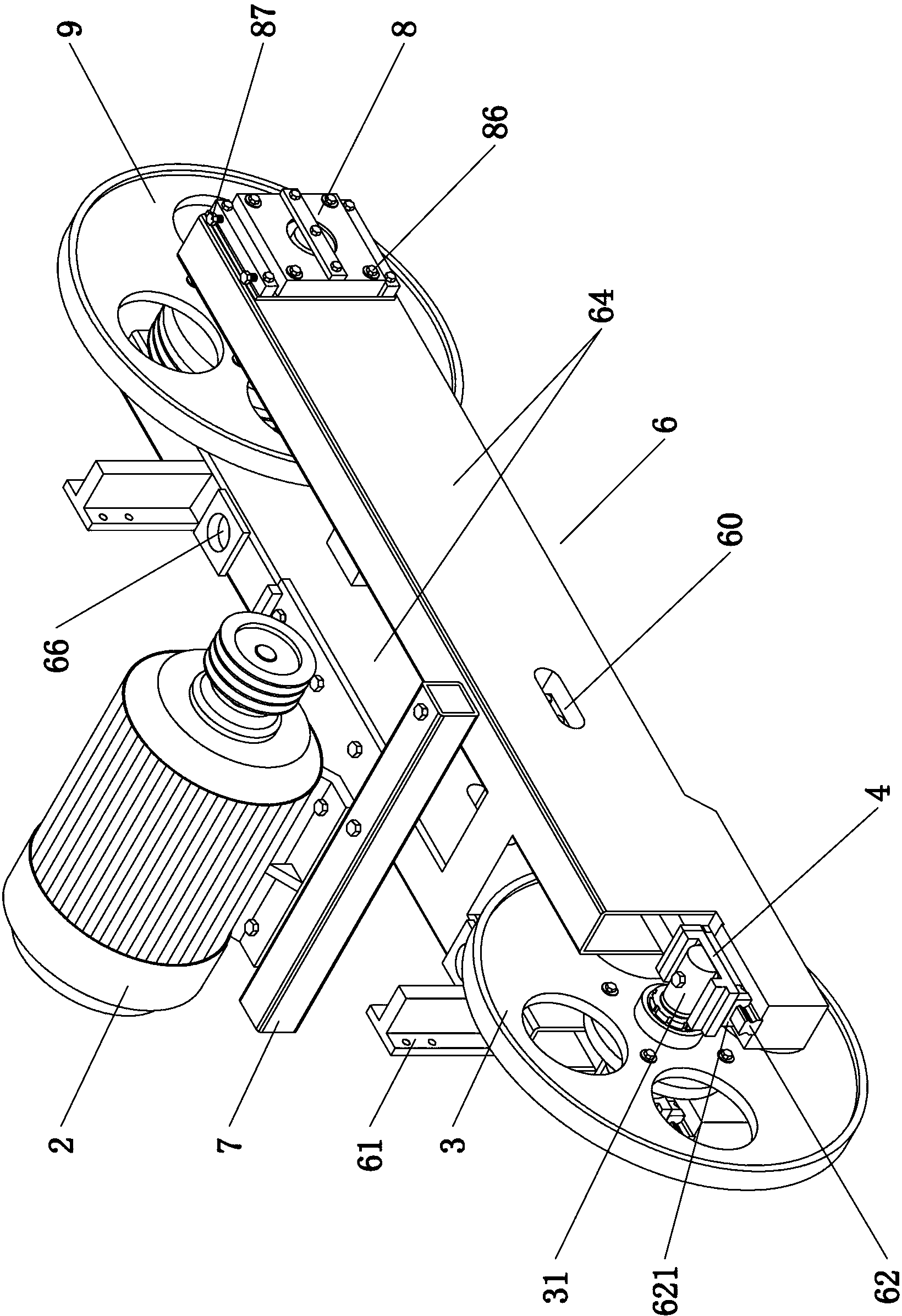

[0026] combine Figure 1 to Figure 3 As shown, a horizontal band saw machine includes a driving saw wheel 9, a passive saw wheel 3, a saw wheel support seat 6 and a tensioning mechanism 4. The center of the active saw wheel 9 is provided with a main positioning shaft 91, and the center of the passive saw wheel 3 is A secondary positioning rotating shaft 31 is provided; the saw wheel support seat 6 includes two front and rear beams 64, and a slot 68 is left between the two beams 64; the tensioning mechanism 4 includes a driving member, a push rod and a yoke 42, The driving part is arranged in the slot 68, the driving part is connected with the push rod in transmission, the middle part of the fork arm 42 is connected with the push rod, and the fork arm 42 is slidingly matched with the beam 64; In one end of the groove 68, the two ends of the auxiliary po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com