Concave chambers of automotive rear tail lights

A technology of rear tail light and cavity, applied in the field of automobile body-in-white, can solve the problems of large matching gap between side wall outer panel and rear tail light, easy water leakage in the tail light area, affecting the appearance of the body grade, etc., so as to avoid stamping cracking and improve the The effect of body sealing and the effect of reducing the risk of deformation of the A side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

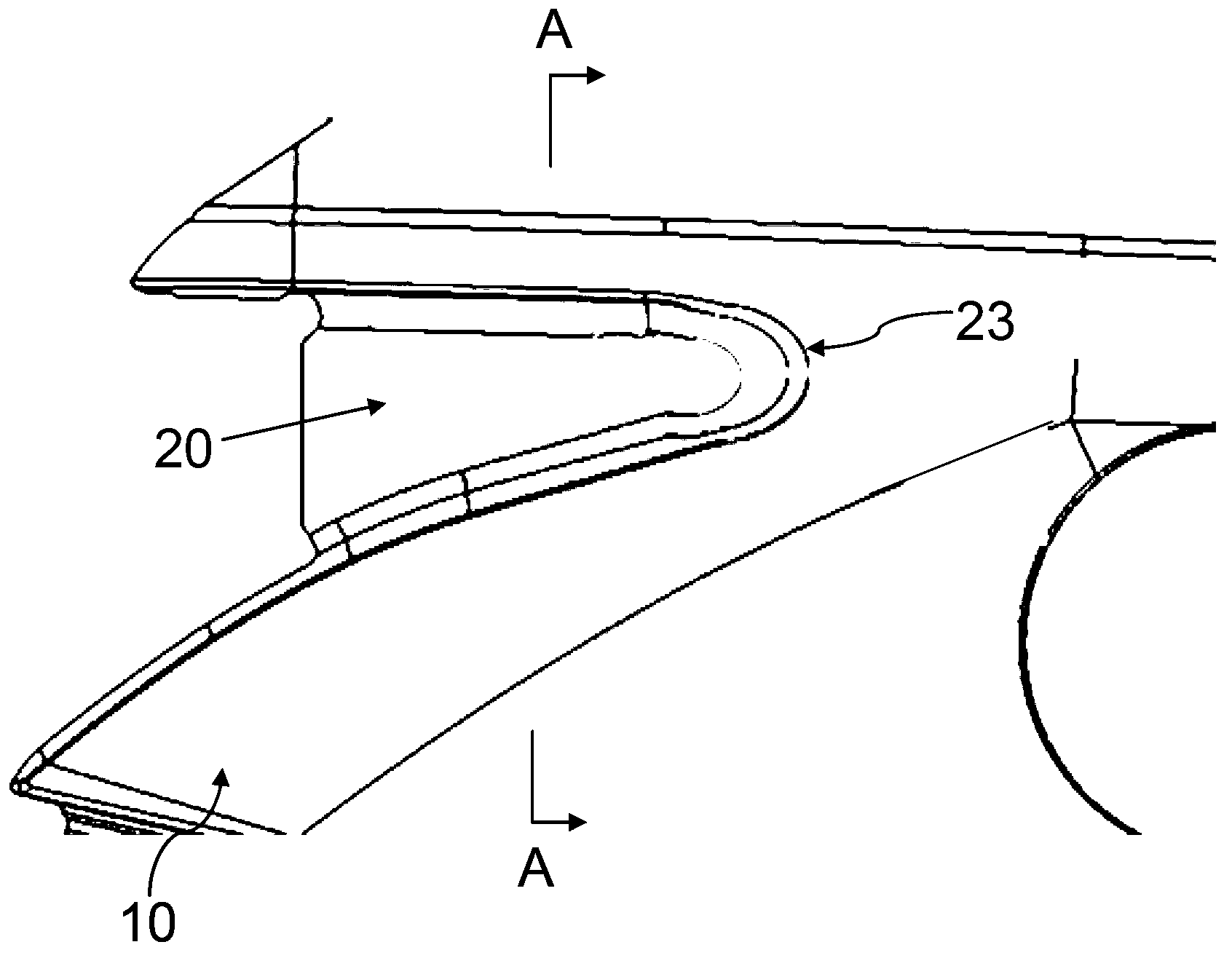

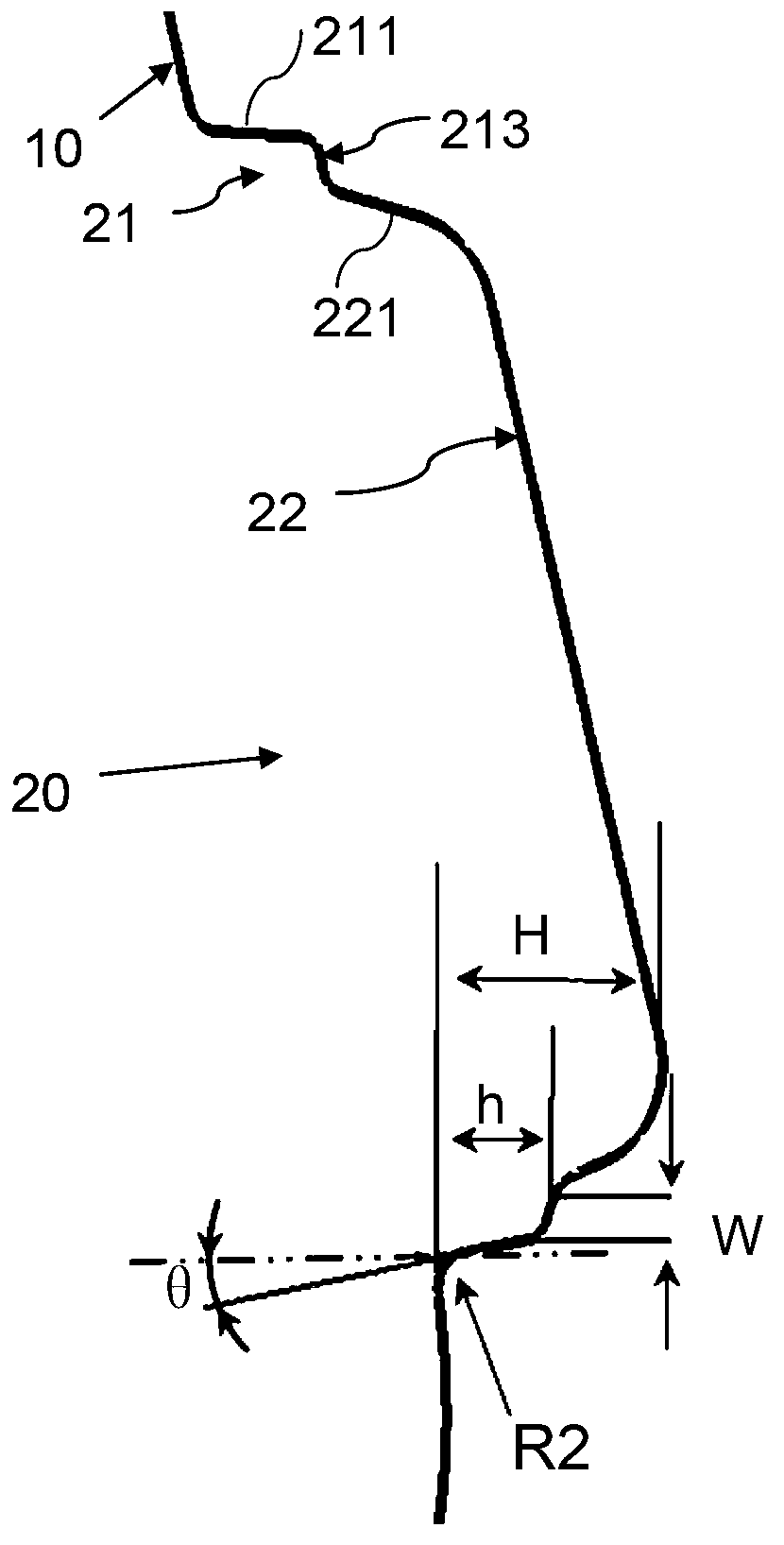

[0008] Such as figure 1 with 2 As shown, an automobile rear tail light cavity is characterized in that: the tail light area of the side wall outer panel 10 is recessed toward the inner side of the vehicle body to form a cavity 20 for placing the rear tail light, and the cavity 20 is a flared stepped chamber , the concave cavity 20 includes a first concave cavity 21 and a second cavity 22, wherein the first concave cavity 21 is connected to the side wall outer panel 10, and the first side wall 211 on the first concave cavity 21 is connected to the side wall outer panel 10 Round corners are adopted for transition between them, and a stepped surface 213 is connected between the second side wall 212 and the first side wall 211 of the second concave cavity 22 .

[0009] The present invention can adopt following manufacturing method, and the steps are as follows:

[0010] a. The tail light area of the side wall outer panel 10 is extended along the Y direction of the vehicle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com