Piece-making and winding joining device

A technology of winding and winding machine, which is applied to the linkage device of drive and tension control, deviation correction, and buffering fields. High precision, eliminate vertical deviation, prevent wrinkling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the principle and structure of the present invention, the preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0035] The film making and winding connection device of the present invention is used for the process control of the pole pieces between the film making system and the winding system of the battery automatic winding machine.

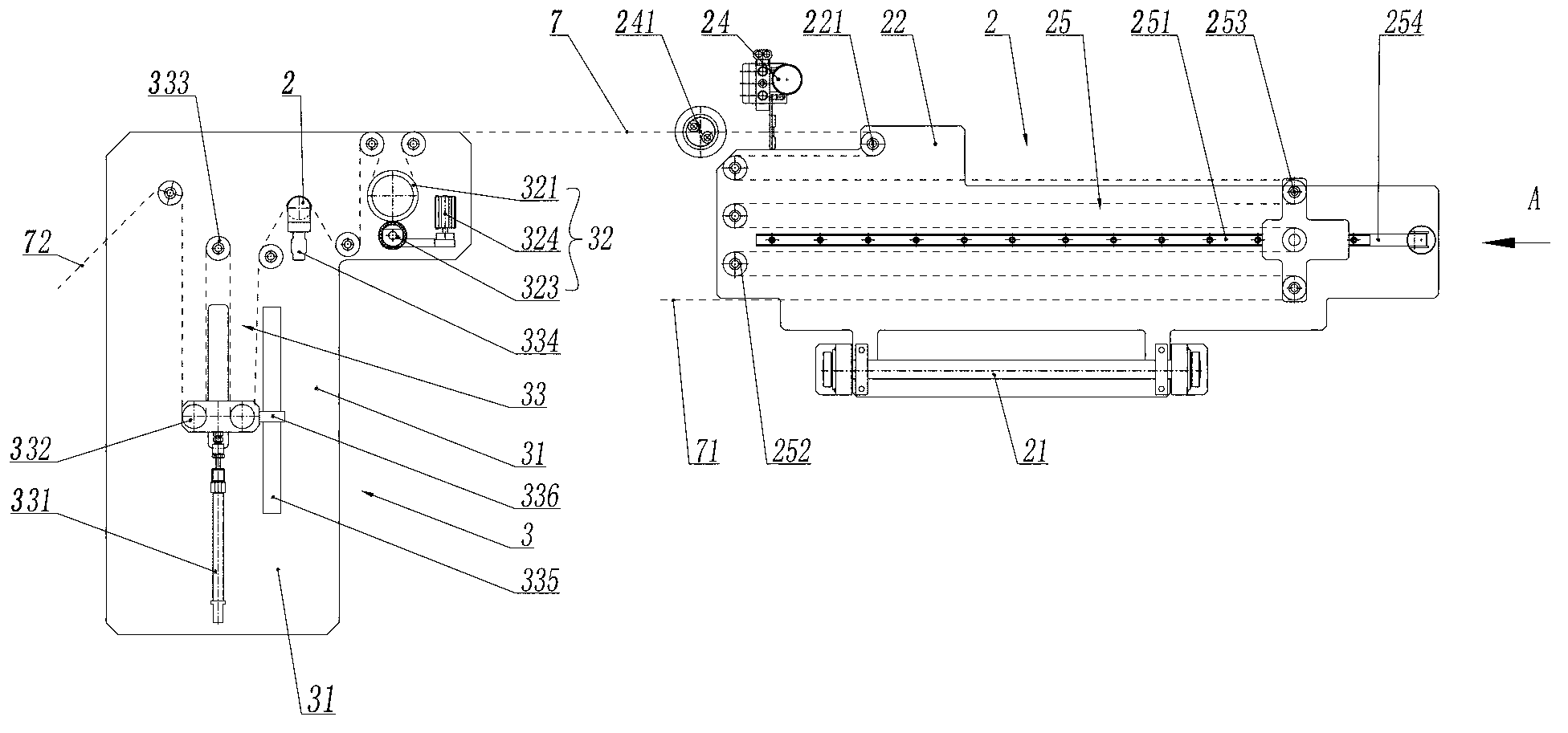

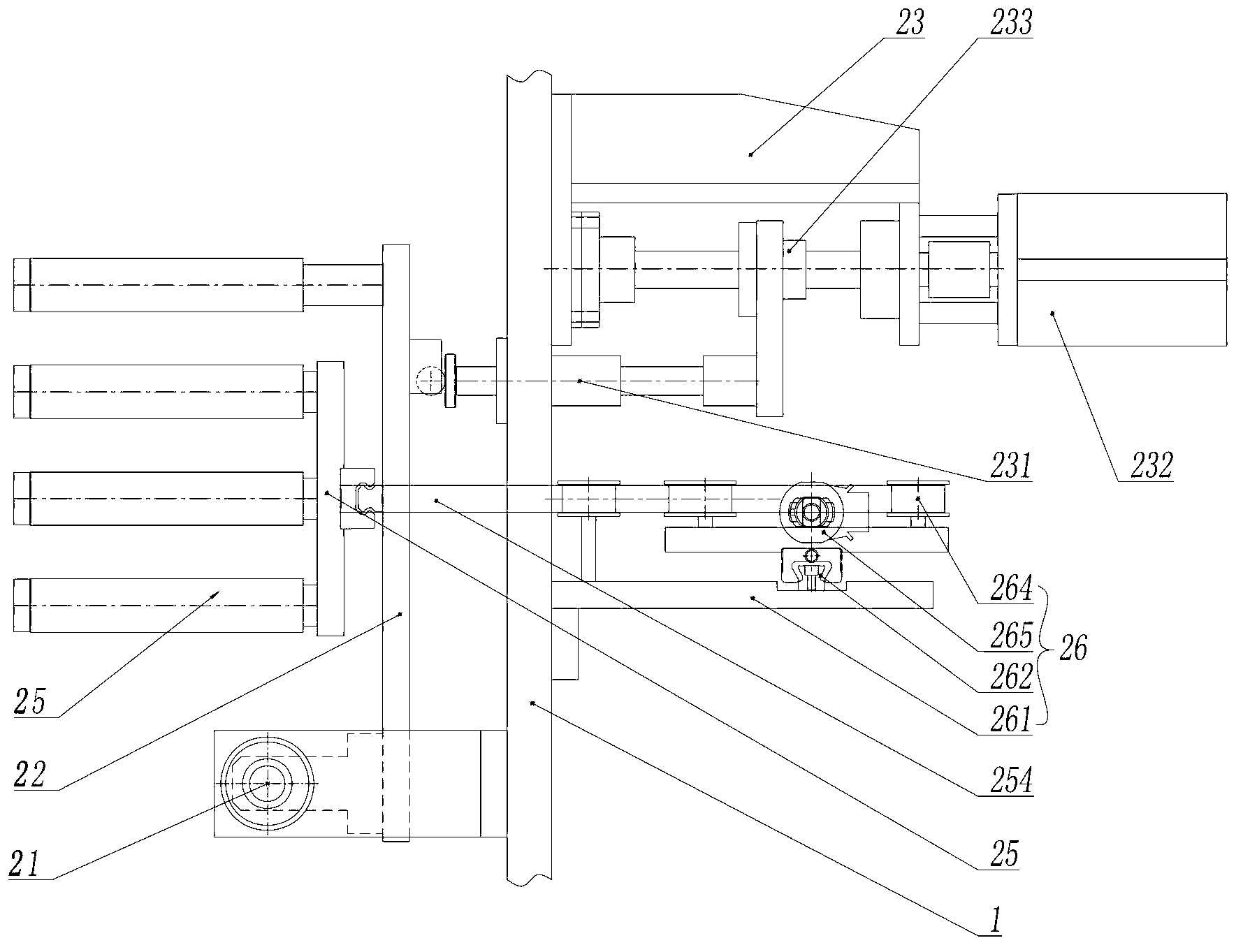

[0036] figure 1 It is a front view of an embodiment of the film-making winding and engaging device of the present invention; figure 2 It is a partial left view of the swing correction part of this embodiment.

[0037] In the figure, the film-making winding and connecting device includes: the main part of the fully automatic winding machine is vertically arranged with a base plate 1, and the conveying direction of the pole piece 7 is parallel to the base plate 1. The swing correction part 2 installed on the base plate 1 is connected to the who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com