Horizontal wheel rail gnawing preventing device for two-force rod system

A technology of two levers and horizontal wheels is applied in the field of horizontal wheel anti-gnawing rail devices, which can solve the problems of increasing maintenance costs, delaying production tasks, cumbersome assembly and disassembly methods, etc. The effect of mechanical influences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

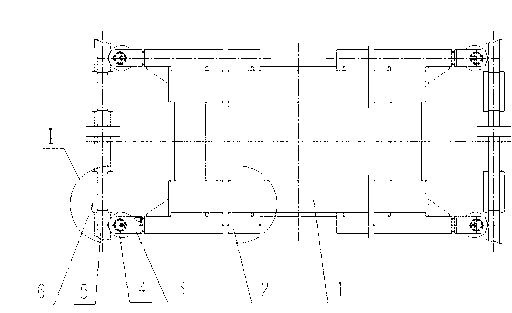

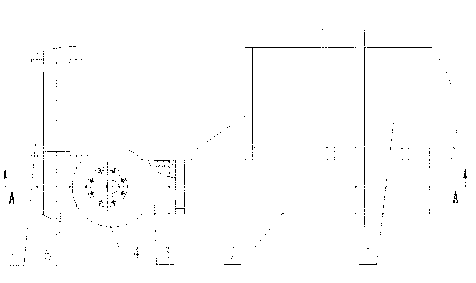

[0029] The utility model relates to a horizontal wheel anti-gnawing rail device of a two-force bar system. The device as figure 1 As shown, it includes four two-force link mechanisms, the fixed ends of the four two-force link mechanisms are symmetrically fixed on the four corners of the main girder 1 of the bridge frame, and the four two-force bar mechanisms are located on both sides of the main beam 1 of the bridge frame. Such as Figure 4 As shown, the installation gap e between the movable ends of the four two-force lever mechanisms and the inner side of the track 5 is 4-6mm. Such as figure 2 As shown, the stiffener plate is welded at the end of main beam 1 and the outer web.

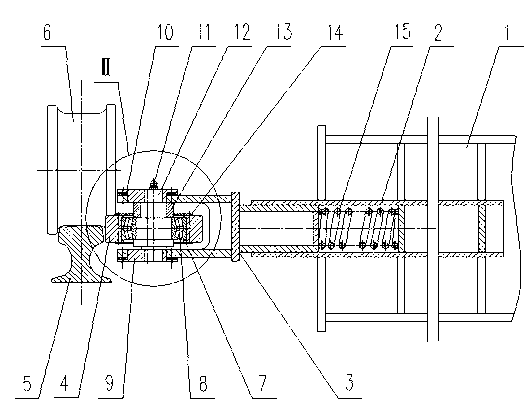

[0030] The size and structure of the 4 two-force lever mechanisms are identical, and all consist of a fixed frame group and a horizontal wheel group.

[0031] Such as image 3 As shown, the fixed frame set includes a box-shaped fixed frame 2 , a compression frame 3 and a compression spring ...

Embodiment 2

[0036] The utility model relates to a horizontal wheel anti-gnawing rail device of a two-force bar system. Except following technical parameter, all the other are with embodiment 1.

[0037] The installation clearance e between the movable ends of the four two-force rod mechanisms and the inner side of the track 5 is 6-8 mm; there are 5-8 radial oil holes on the wall of the stepped hole of the shaft sleeve 13; the eccentric transparent cover 9 is evenly arranged with 4 ~7 or 9~12 screw holes; the distance between the eccentric holes of the eccentric transparent cover 9 is b=20~25mm.

[0038] In this specific embodiment, during installation, the vertical centerline of the wheel 6 and the vertical centerline of the track 5 tend to be close to or even overlap, so as to balance the force couple and the reaction couple produced by the lateral force on the track 5 on both sides, and reduce the size of the lateral force on the rail. .

[0039] Compared with the prior art, this spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com