Geopolymer tunnel fireproof coating and preparation method thereof

A technology of geopolymers and fireproof coatings, applied in the production of fireproof coatings, cement, etc., can solve the problems of inconvenient and uneconomical use of two-components, achieve low cost of material sources, excellent freeze-thaw resistance, and bond strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment provides the geopolymer tunnel fireproof coating, which consists of the following raw materials in units of weight: 43 parts of geopolymer, 12 parts of expanded perlite, 24 parts of expanded vermiculite, 14 parts of brucite fiber, sepiolite 4 parts, 3 parts of hydroxymethyl cellulose, 0.03 part of fatty alcohol sulfonate air-entraining agent;

[0045] The geopolymer, in terms of weight unit, consists of the following raw materials: 17 parts of silica fume, 10 parts of kaolin, 3 parts of calcium-based bentonite, 5 parts of calcium oxide, 10 parts of sodium carbonate, 2 parts of sodium chloride, sodium sulfate 3 parts, 50 parts of low calcium fly ash.

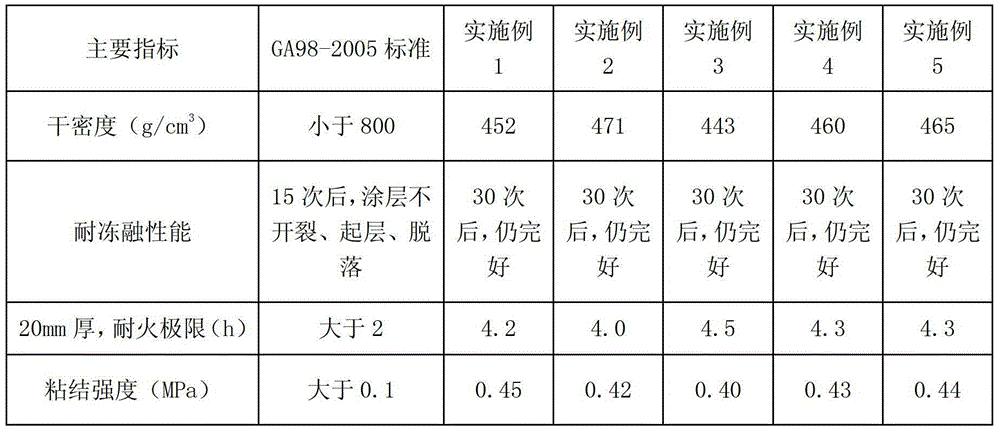

[0046] The various performance parameters of the geopolymer tunnel fireproof coating prepared in this embodiment are shown in Table 1.

Embodiment 2

[0048] The present embodiment provides the geopolymer tunnel fireproof coating, which is composed of the following raw materials in parts by weight: 45 parts of geopolymer, 10 parts of expanded perlite, 22 parts of expanded vermiculite, 13 parts of brucite fiber, sea foam 5 parts of stone, 5 parts of hydroxymethyl cellulose, 0.05 part of fatty alcohol sulfonate air-entraining agent;

[0049]The geopolymer, in terms of weight unit, consists of the following raw materials: 17 parts of silica fume, 10 parts of kaolin, 3 parts of calcium-based bentonite, 5 parts of calcium oxide, 10 parts of sodium carbonate, 2 parts of sodium chloride, sodium sulfate 3 parts, 50 parts of low calcium fly ash.

[0050] The various performance parameters of the geopolymer tunnel fireproof coating prepared in this embodiment are shown in Table 1.

Embodiment 3

[0052] The present embodiment provides the geopolymer tunnel fireproof coating, which consists of the following raw materials in units of weight: 35 parts of geopolymer, 12 parts of expanded perlite, 28 parts of expanded vermiculite, 15 parts of brucite fiber, sepiolite 5 parts, 5 parts of hydroxymethyl cellulose, 0.05 part of fatty alcohol sulfonate air-entraining agent;

[0053] The geopolymer, in terms of weight unit, consists of the following raw materials: 17 parts of silica fume, 10 parts of kaolin, 3 parts of calcium-based bentonite, 5 parts of calcium oxide, 10 parts of sodium carbonate, 2 parts of sodium chloride, sodium sulfate 3 parts, 50 parts of low calcium fly ash.

[0054] The various performance parameters of the geopolymer tunnel fireproof coating prepared in this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com