Composite water-permeable material, and production method and derivative products thereof

A water-permeable material and water-permeable pipe technology, applied in sustainable manufacturing/processing, chemical industry, climate sustainability, etc., can solve problems affecting the use effect of rubber permeable irrigation pipes, hole blockage, and uncontrollable foam-forming technology, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

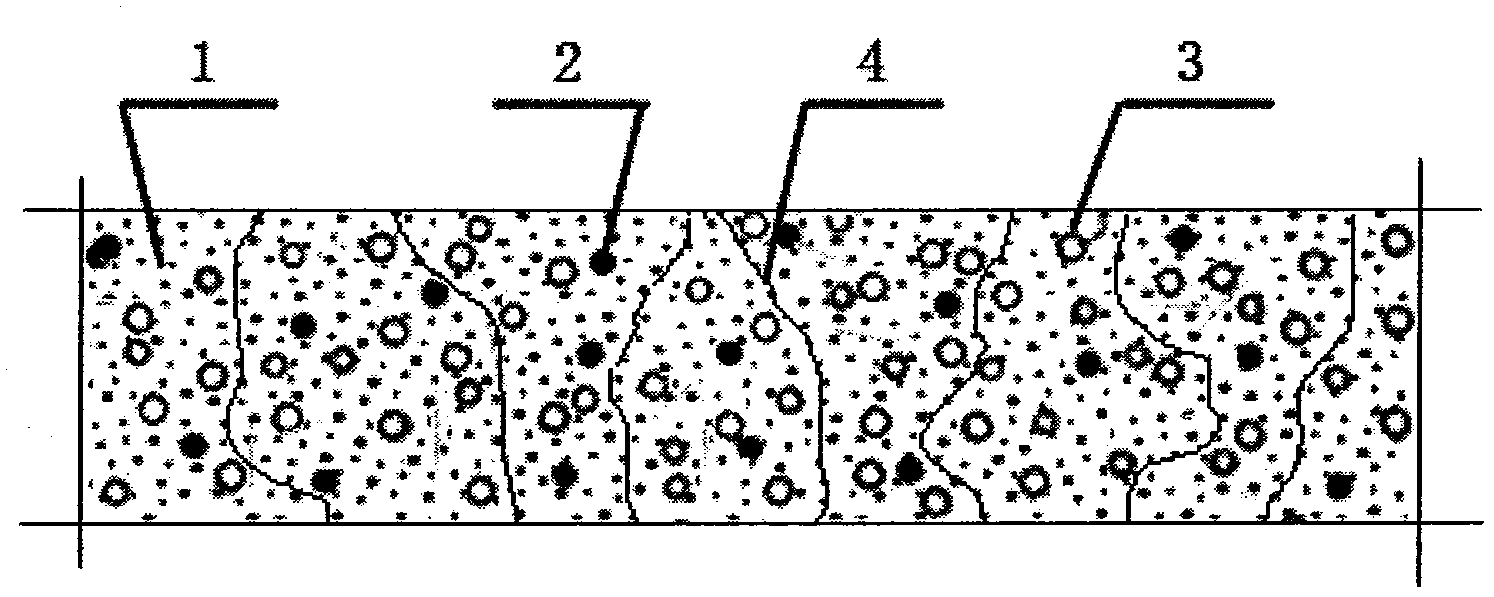

[0030] Attached below figure 1 The composite water-permeable material in the present invention will be further described in detail with specific embodiments.

[0031] Such as figure 1 The composite water-permeable material shown is formed by mixing various components, and its components include: chemical material base material 1, plasticizer 2 added to the chemical material base material, and nano-scale holes added to the chemical material base material , and a filler 3 coated with a release agent;

[0032] Wherein, the weight and number ratio of the plasticizer 2 and the chemical material base material 1 is 5:100 to 20:100, and the weight and number ratio of the filler 3 and the chemical material base material 1 is 10:100 to 40: 100, the ratio of parts by weight of the release agent to the filler 3 is 10:100 to 20:100;

[0033] The chemical material base 1 includes PE material, or PVC material, or PP material, or any combination of the three; the plasticizer 2 is a materia...

Embodiment 2

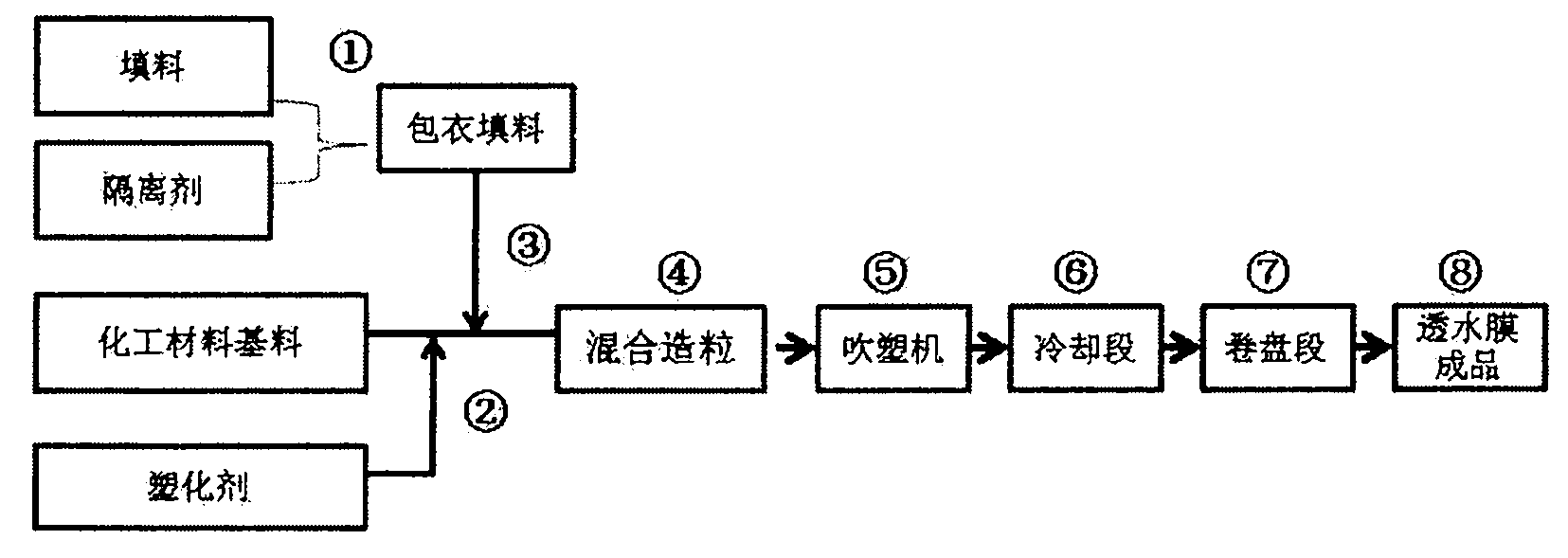

[0037] Attached below figure 2 The preparation of the water-permeable membrane in the present invention will be further described in detail with specific embodiments.

[0038] Such as figure 2 As shown, first take corresponding parts of chemical material base material 1, plasticizer 2, filler 3, and release agent, and perform the following steps:

[0039] 1. Add the above filler 3 into the mixer. After the mixer is running, add the corresponding amount of release agent into the mixer at a constant speed through the atomization nozzle installed on the mixer within a set period of time. In the machine, the filler 3 is uniformly coated, and after the release agent is filled, the mixer continues to run for a certain period of time, so that the filler 3 and the release agent are completely mixed evenly to form a coated filler for later use;

[0040] 2. Add the corresponding parts of chemical material base material 1 and plasticizer 2 into the high-speed mixer for mixing and sti...

Embodiment 3

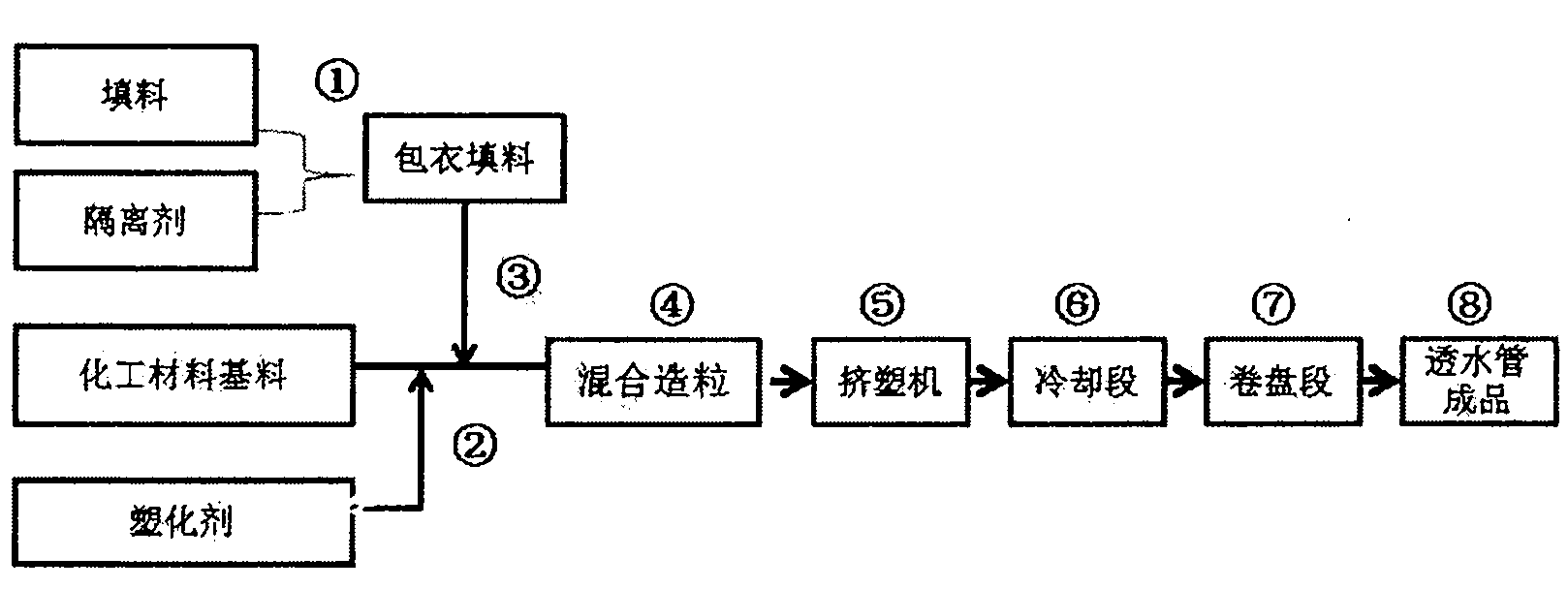

[0048] Attached below image 3 The preparation of the water-permeable pipe in the present invention will be further described in detail with specific embodiments.

[0049] Such as image 3 As shown, first take corresponding parts of chemical material base material 1, plasticizer 2, filler 3, and release agent, and perform the following steps:

[0050] 1. Add the above filler 3 into the mixer. After the mixer is running, add the corresponding amount of release agent into the mixer at a constant speed through the atomization nozzle installed on the mixer within a set period of time. In the machine, the filler 3 is uniformly coated, and after the release agent is filled, the mixer continues to run for a certain period of time, so that the filler 3 and the release agent are completely mixed evenly to form a coated filler for later use;

[0051] 2. Add the corresponding parts of chemical material base material 1 and plasticizer 2 into the high-speed mixer for mixing and stirring;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com