Tee joint check valve

A through-stop, three-way technology, applied in multi-way valves, control valves, valve devices, etc., can solve the problems of tightness, loose valve core, etc., to simplify the pipeline, have good sealing performance, and save movable flanges and seals. circle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

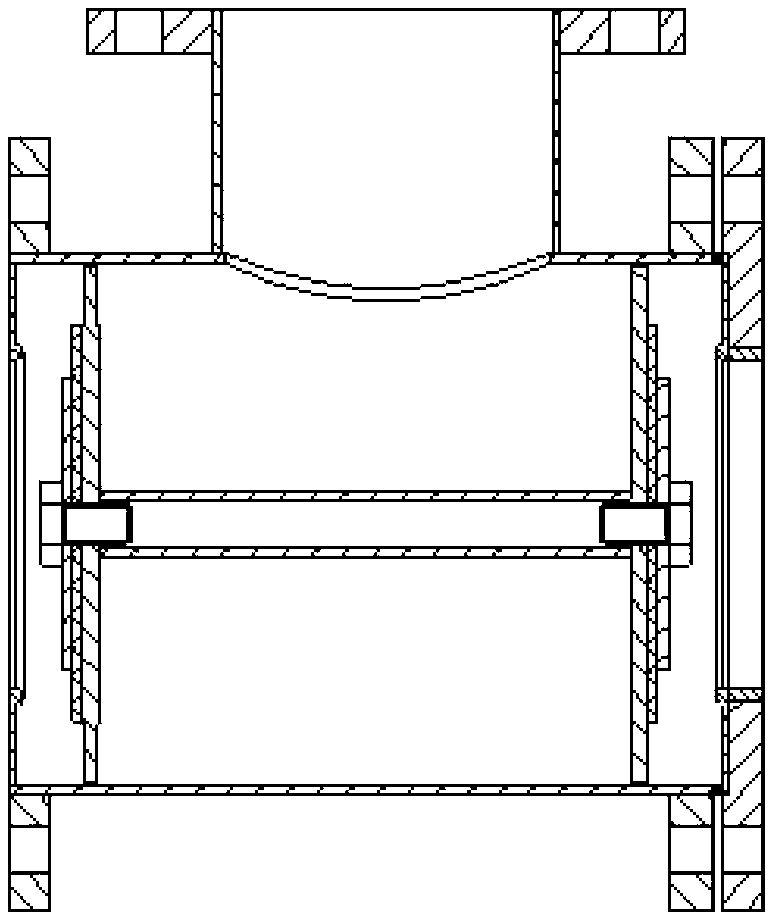

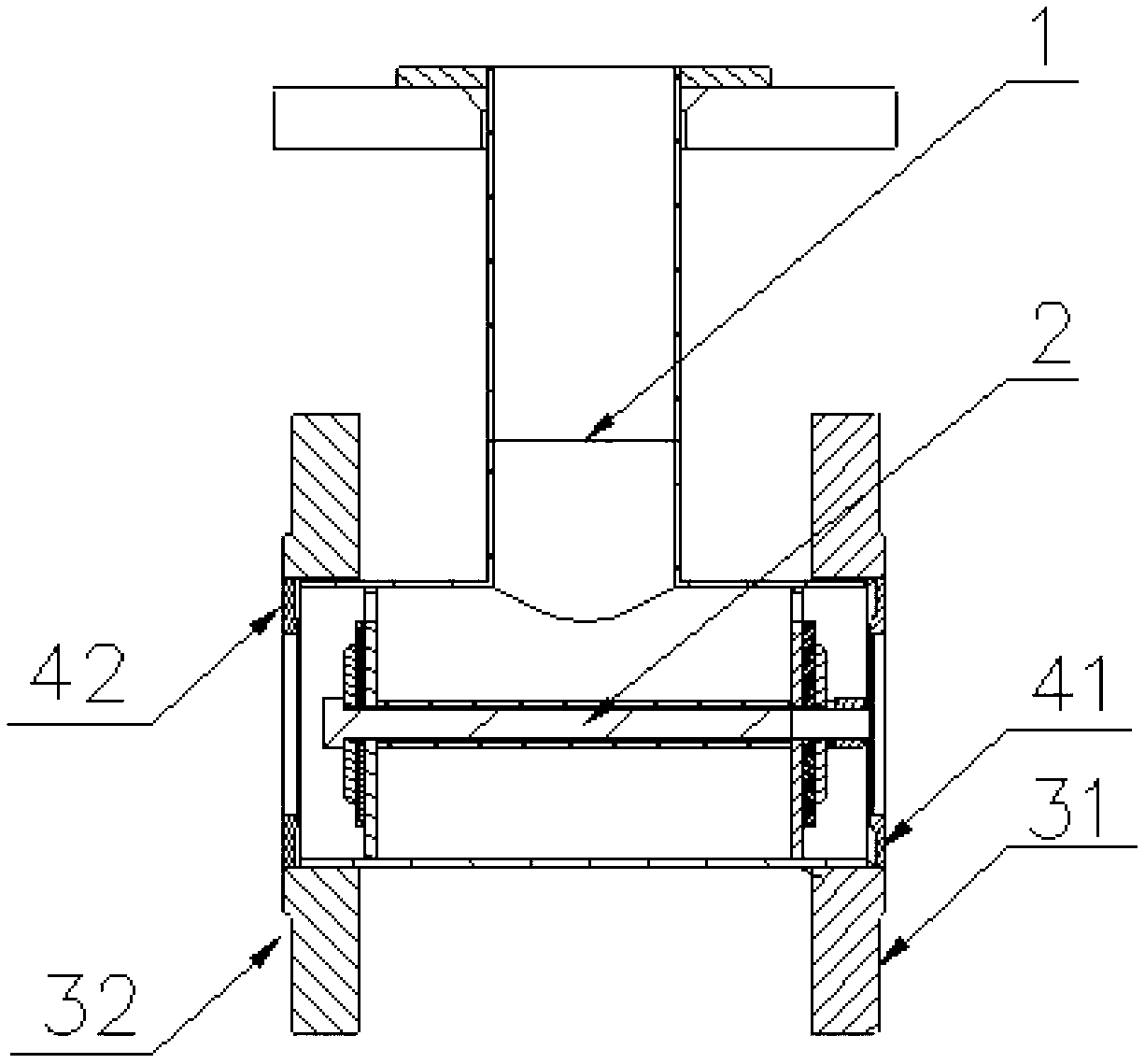

[0014] Such as figure 2 As shown, a three-way check valve includes a three-way base body 1, a movable valve core 2, flanges 3-1, 3-2 and sealing rings 4-1, 4-2, flanges 3-1 and 3 -2 are respectively connected to the two ends of the three-way base body 1 by welding, and form an annular groove matching the sealing retainer ring 4-1 and 4-2, the sealing retainer ring 4-1 and 4-2 are embedded in the annular groove, and the valve core is movable 2 is placed in the three-way base body 1, and can be engaged with the sealing retaining rings 4-1 and 4-2 to form a sealing surface to block the flow path.

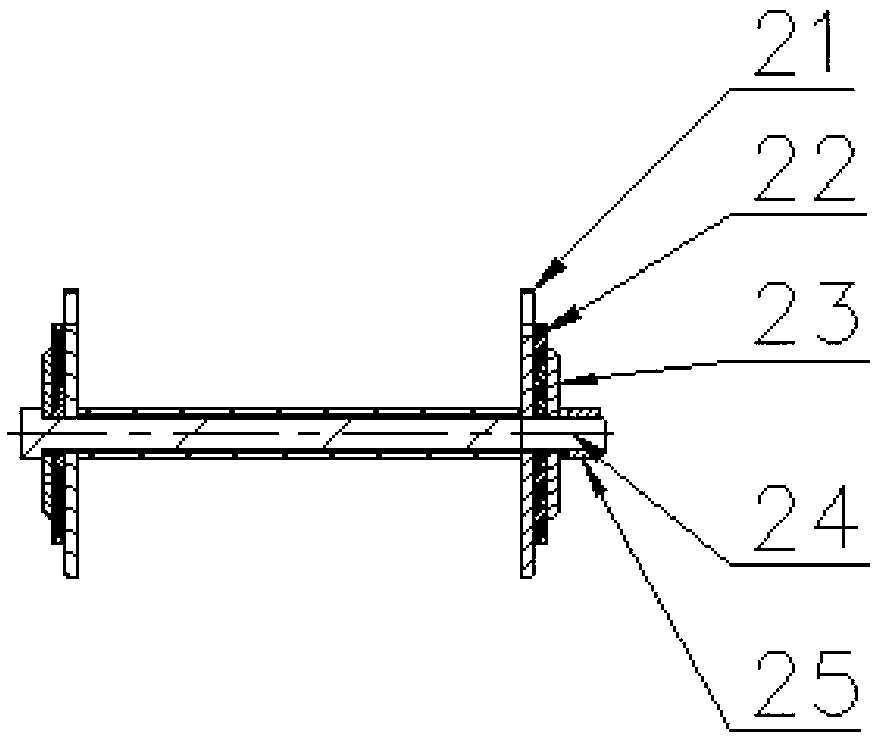

[0015] Such as image 3 The movable valve core 2 shown includes an I-shaped valve chip 21, a sealing ring 22, a pressure plate 23, a bolt 24, and a nut 25. The bolt 24 penetrates the I-shaped valve chip 21, the sealing ring 22 and the pressure plate 23, and is then fixed by a nut 25. The nut 25 Welded on the bolt 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com