Rapid surface shape detection method for circular convex aspheric surfaces

A surface shape detection and aspheric technology, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of compensator detection, the impact of detection results is great, time-consuming, etc. The effect of obvious cost performance and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

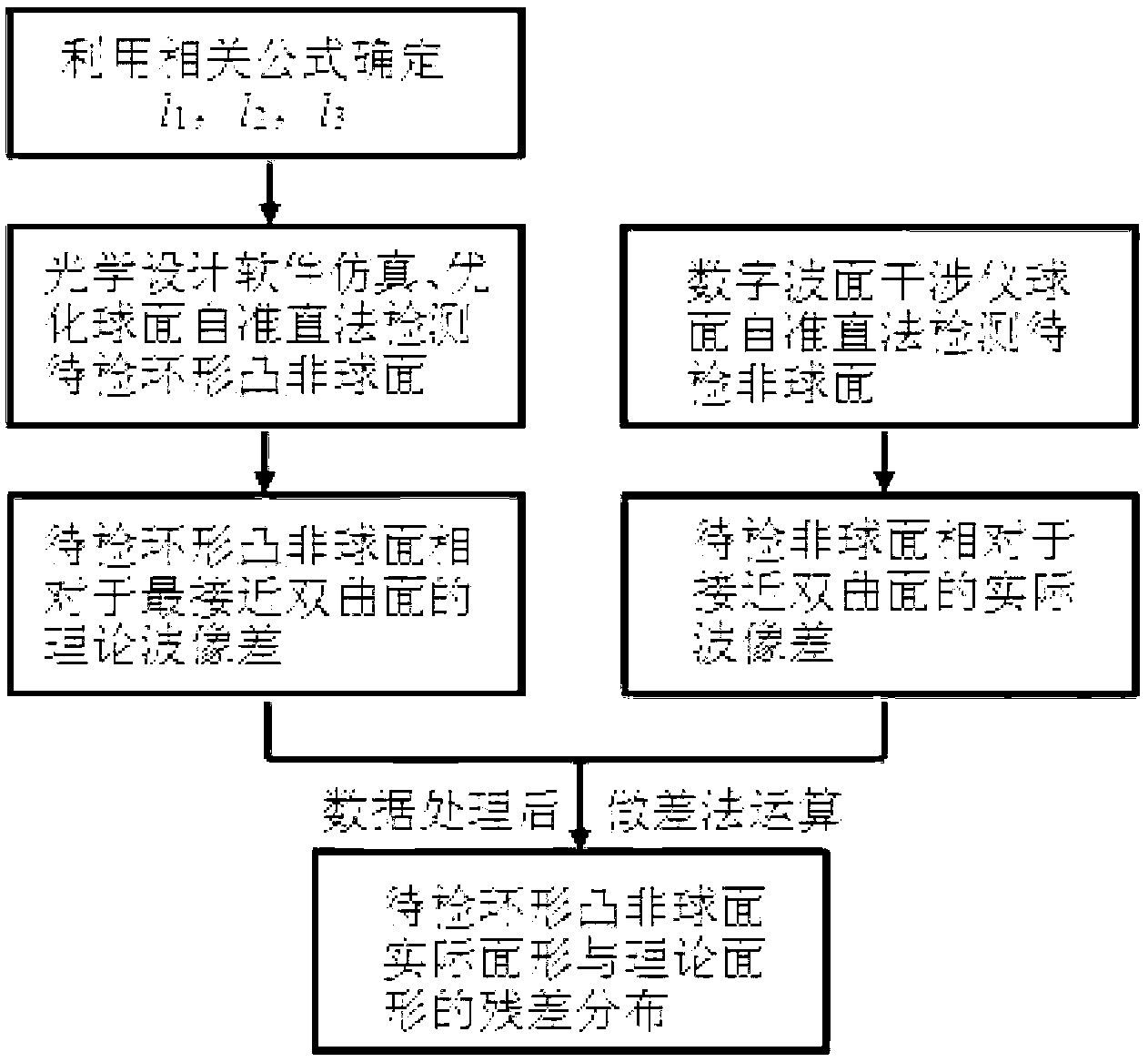

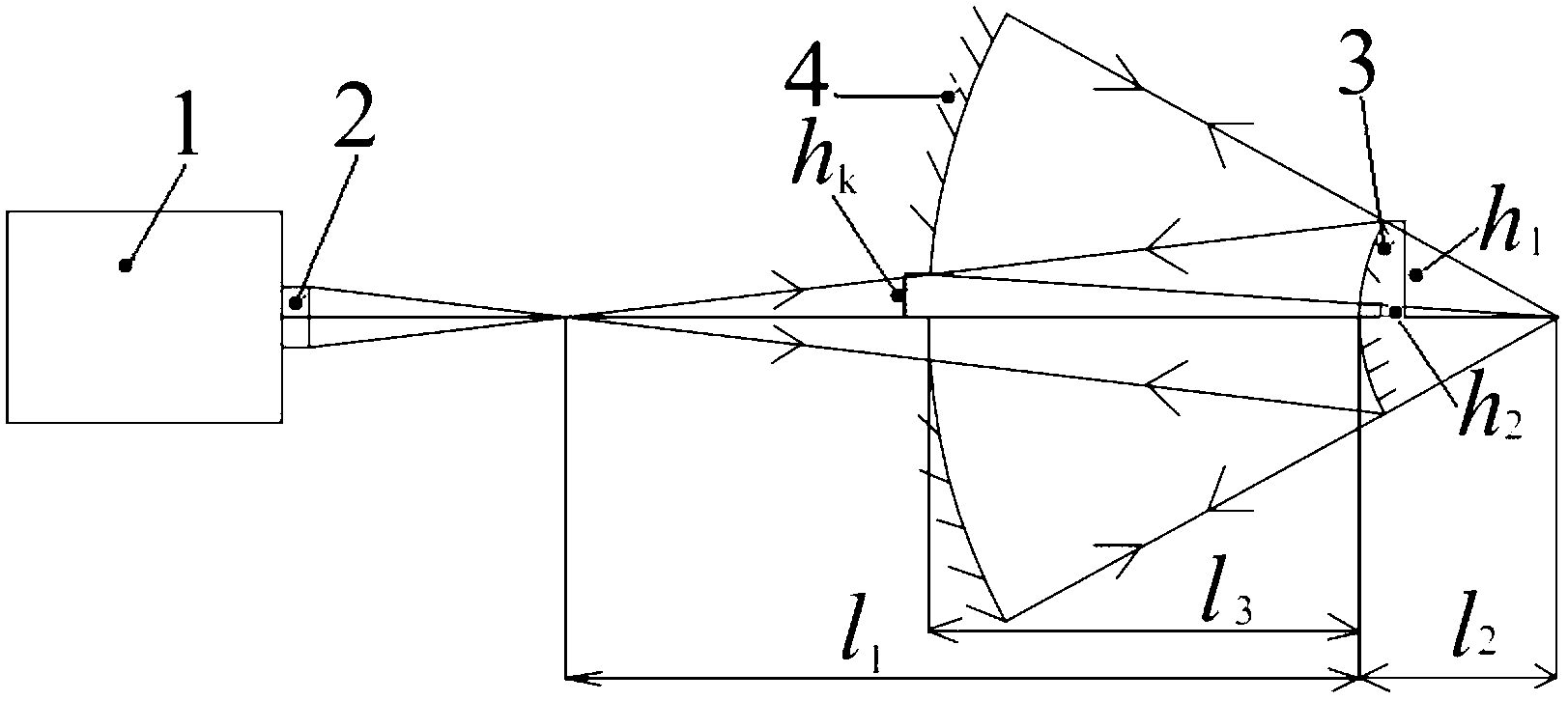

[0023] A rapid surface shape detection method for a circular convex aspheric surface. figure 1 It is a working principle diagram of the present invention.

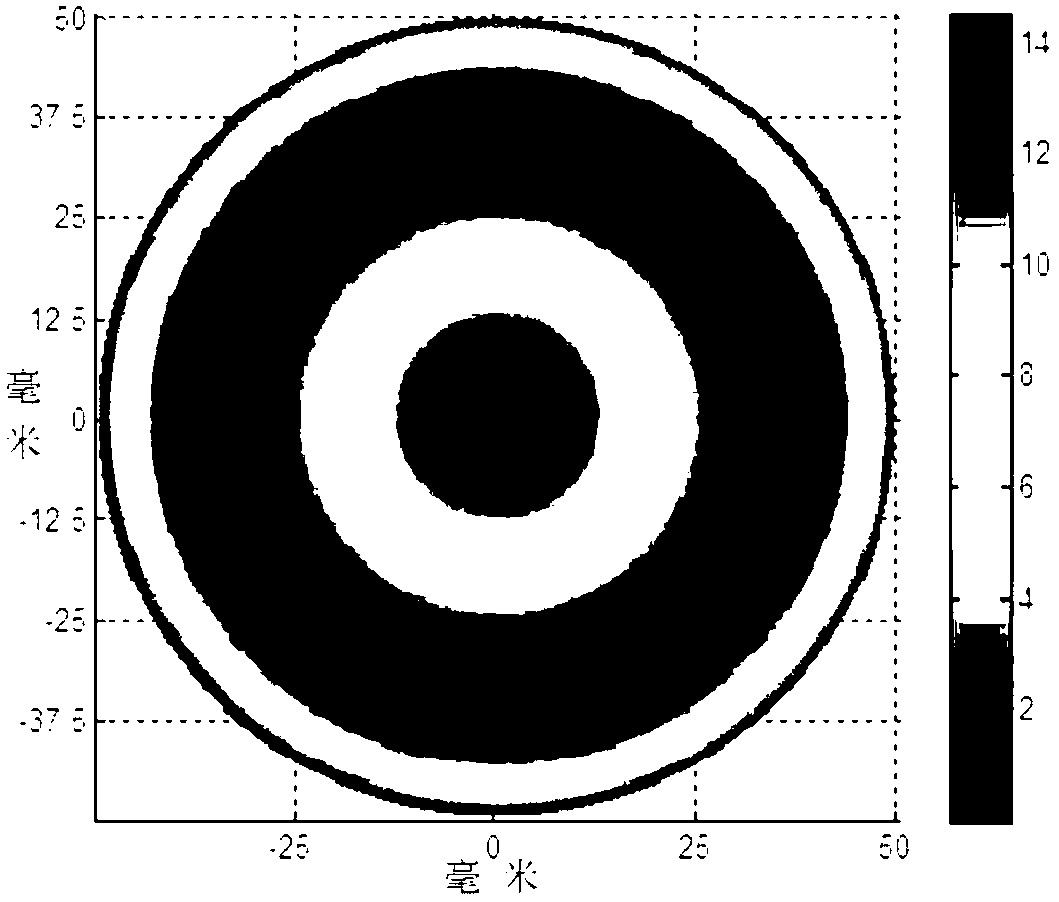

[0024] According to the parameters of existing related components and equipment, calculate the parameters closest to the hyperboloid, and determine l 1 , l 2 and l 3 . For example, to detect a convex paraboloid with an effective light-passing diameter of Φ=8 to 100 mm, apex curvature radius r=236.2 mm, and eccentricity K=-1, there is a standard spherical mirror with a curvature radius R=557.01 mm, h k =22 mm, D=550 mm, calculated according to the above formula: h 1 = 4 mm, h 2 =50 mm, α=0.08, β=8.03, l 1 =830.42 mm, l 2 =103.42 mm, l 3 =464.96 mm, e=1.284, ie K=-1.649.

[0025] According to the above initial structural parameters, use optical design software...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com