Insulator air-water inspection device

A technology for inspection devices and insulators, which is applied in the direction of applying stable tension/pressure to test material strength, liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of complex structure and cost of insulator air tightness and water pressure inspection devices High, inconvenient use and other problems, to achieve the effect of simple structure, reduce inspection cost, and meet inspection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

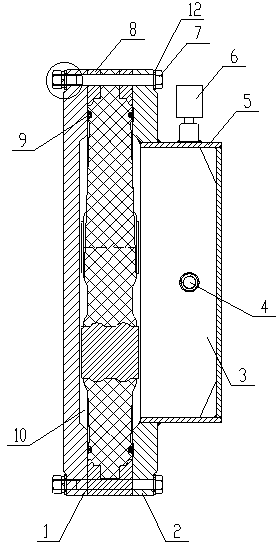

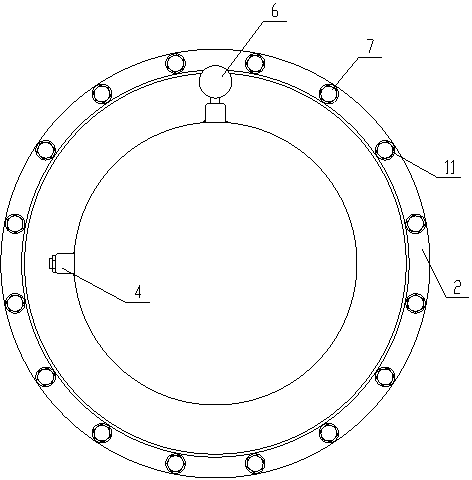

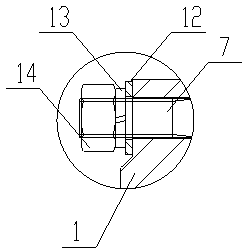

[0011] As shown in the figure, it includes a left cover plate 1 and a right cover plate 2. The right surface edge of the left cover plate 1 is provided with an annular sealing ring 9, and a concave plane 11 is provided in the middle. The left cover plate 1 Sixteen fixing holes are evenly distributed on the edge of the plate 1; the left surface edge of the right cover plate 2 is provided with an annular sealing ring 9, and a concave air chamber 3 is provided in the middle, and the air chamber side wall 5 of the air chamber 3 A pressure gauge 6 is fixed on the outer surface, and a joint 4 is arranged on the outer surface of the side wall 5 of the air chamber perpendicular to the position of the pressure gauge. The pressure gauge 6 and the joint 4 communicate with the air chamber 3 through a through hole respectively. Sixteen fixing holes are evenly distributed on the edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com