Intelligentized digital grain depot monitoring system

A technology of supervision system and grain depot, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of low degree of data informatization, inability to complete complex control tasks, inability to understand grain depot information, etc. The effect of improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

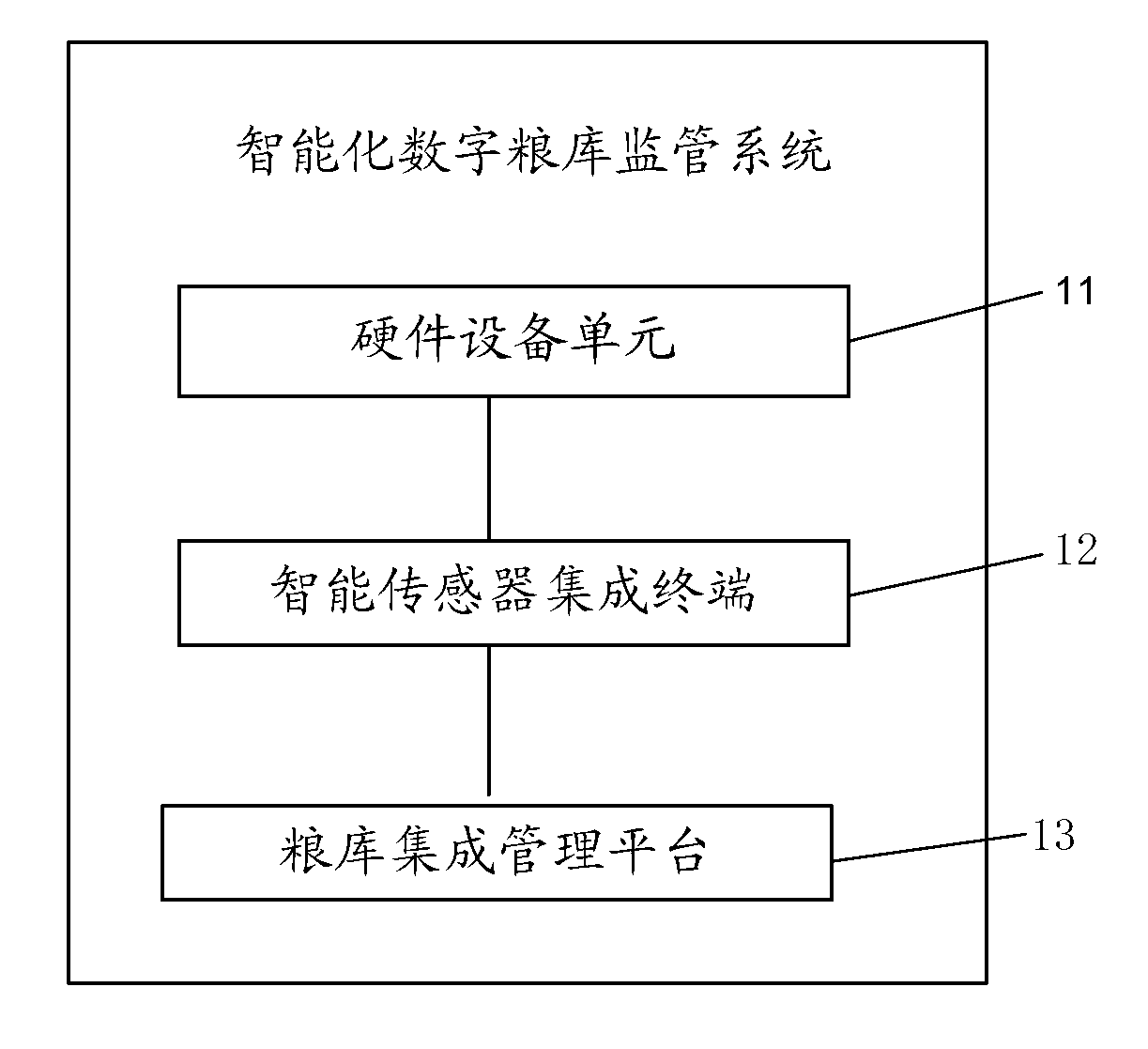

[0030] The specific structure of an intelligent digital grain depot supervision system provided by this embodiment is as follows: figure 1 As shown, it includes the following modules: a hardware device unit 11 , an intelligent sensor integrated terminal 12 and a grain depot integrated management platform 13 .

[0031] Among them, the hardware device unit 11 includes various wired or wireless sensors such as temperature and humidity, as well as grain pile temperature measuring cables, ventilation equipment, temperature adjustment equipment, fumigation equipment, gas collection equipment, pest detection equipment, etc., used to collect various The business data of the specific service is sent to the smart sensor integration terminal 12 .

[0032] The smart sensor integration terminal 12 is used to analyze the business data in various message formats reported by the hardware device units through heterogeneous integration technology, and then convert them into business data in a u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com