Hollow shaft type hydrostatic bearing dynamic designing method

A static pressure bearing and dynamic design technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as low operational reliability, frequent failures, high operational energy consumption and high maintenance costs, and improve operational reliability Sexuality and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

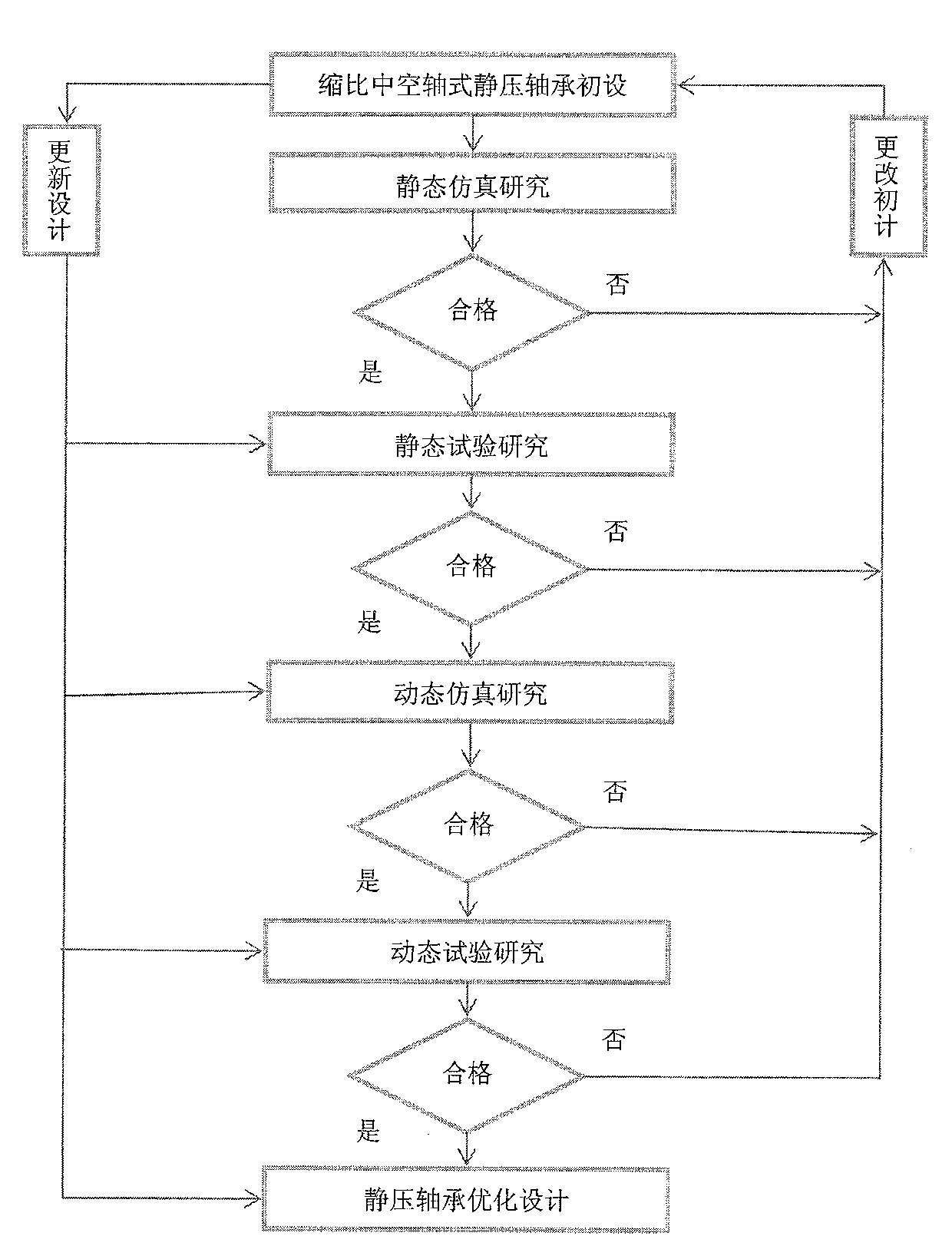

[0013] control figure 1 Shown, method of the present invention comprises the following steps:

[0014] (1) Preliminary design of the scaled hollow shaft hydrostatic bearing. Referring to a large ball mill, according to similar theory, a scaled ball mill with hollow shaft hydrostatic bearing is designed.

[0015] (2) Carry out the static simulation research of the hollow shaft hydrostatic bearing of the reduction ratio ball mill. Including: simplification of the whole machine assembly model, unit selection, determination of boundary conditions and analysis of simulation results. The working condition of the static simulation is full load static, based on the simulation of the contact boundary conditions between the hollow shaft and the bearing bush, the self-aligning bearing liner and the saddle seat, if the static simulation of the hollow shaft hydrostatic bearing fails, change the hollow shaft hydrostatic bearing The initial design of the bearing, until the static simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com