A kind of preparation method of patterned graphene conductive film

A technology of graphene film and conductive film, which is applied in the direction of carbon-silicon compound conductors, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problems affecting the conductivity of graphene and the conductivity of conductive films, etc. Short film time, clear pattern and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The flexible substrate polyimide (PI) was cleaned and dried, and the PI substrate was etched with oxygen plasma. The gas flow rate of etching was 100sccm, the power was 100W, and the etching time was 30s; gravure was used Printing process, the graphene oxide ink with a concentration of 30mg / mL prepared by the Hummers method is evenly brushed on the steel plate with a gravure pattern, and then the ink is embossed on the PI substrate to print a patterned graphene oxide film , and finally put the film in an oven, dry at 80°C for 30 minutes; place the graphene oxide film in a tube furnace filled with inert gas, and anneal at 400°C for 2 hours to obtain a patterned graphene conductive film.

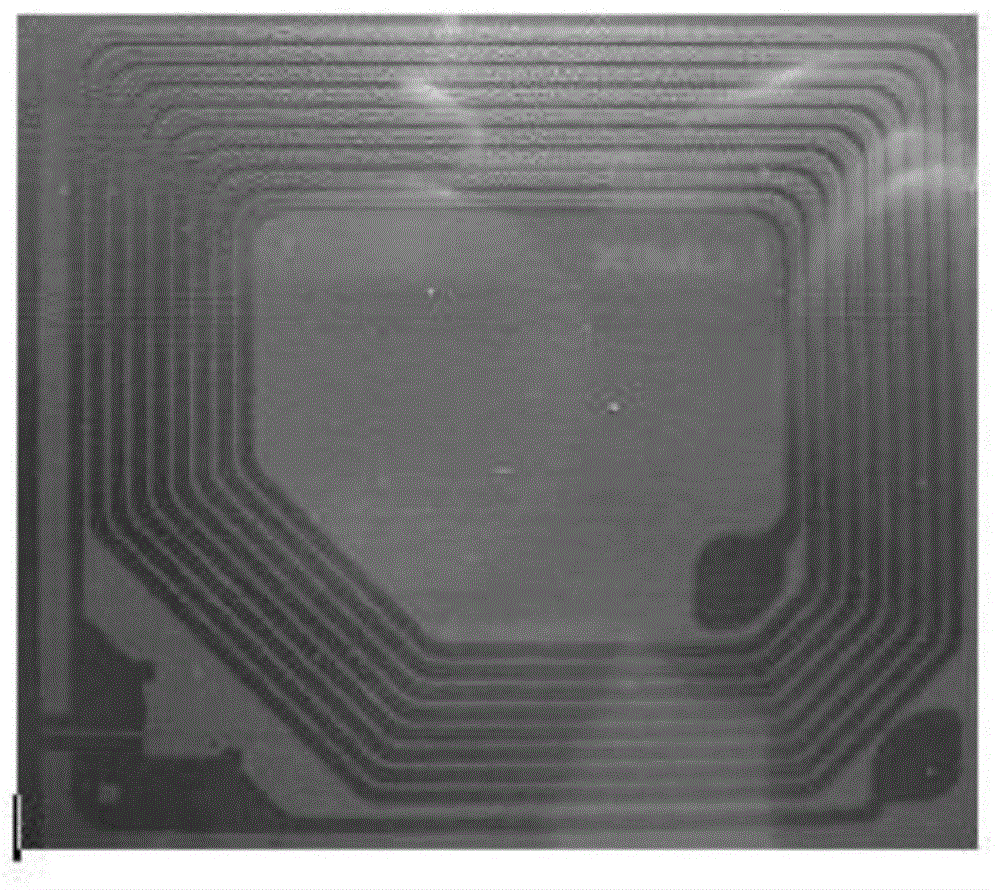

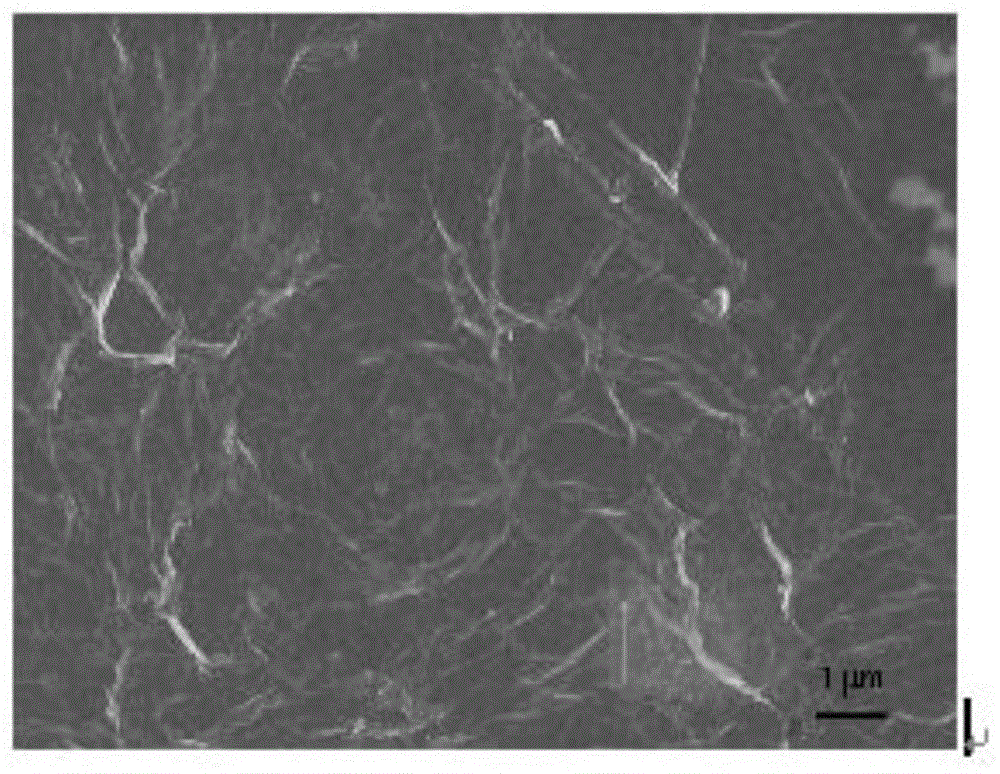

[0029] figure 1 It is an optical microscope image of a patterned graphene conductive film printed on a flexible PI substrate. It can be seen from the figure that the pattern is very clear. figure 2 Field emission scanning electron microscope image of a patterned graphene conductive fi...

Embodiment 2

[0031] The flexible substrate polyimide (PI) was cleaned and dried, and the PI substrate was etched with oxygen plasma. The gas flow rate for etching was 100sccm, the power was 100W, and the etching time was 90s; gravure was used Printing process, the graphene oxide ink with a concentration of 30mg / mL prepared by the Hummers method is evenly brushed on the steel plate with a gravure pattern, and then the ink is embossed on the PI substrate to print a patterned graphene oxide film , and finally put the film in an oven and dry at 80°C for 20 minutes; place the graphene oxide film in a tube furnace filled with inert gas, and anneal at 400°C for 1.5 hours to obtain a patterned graphene conductive film.

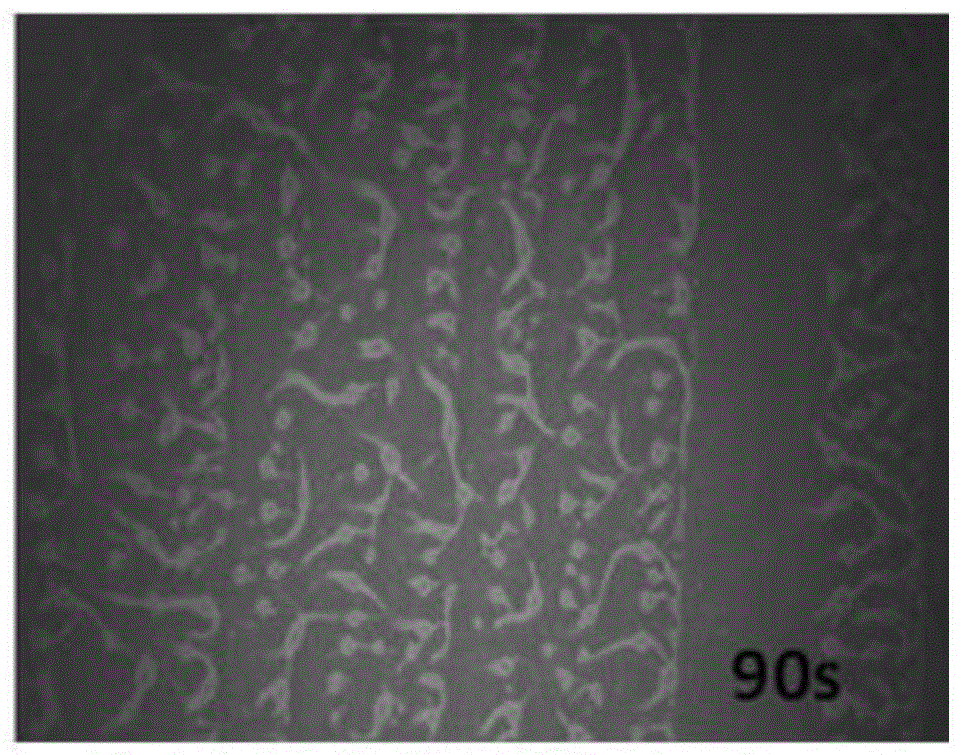

[0032] image 3 It is an optical microscope image of a graphene oxide ink brush with a concentration of 30mg / mL on a PI substrate with an etching treatment time of 90s, and the clarity of the pattern is quite high.

Embodiment 3

[0034] Wash and dry the flexible substrate polyethylene terephthalate (PET), and use oxygen plasma to etch the PI substrate. The gas flow rate for etching is 100 sccm, the power is 100W, and the etching time is 50s; using the gravure printing process, evenly brush the graphene oxide ink with a concentration of 50mg / mL prepared by the Hummers method (after testing, the viscosity of the graphene oxide ink is 62mPa·s) on the steel plate with the gravure pattern , and then imprint the ink on the PET substrate, print a patterned graphene oxide film, and finally put the film in an oven and dry it at 75°C for 30 minutes; put the graphene oxide film in an inert gas In a tube furnace, annealing treatment was performed at 250°C for 2 hours to obtain a patterned graphene conductive film.

[0035] The patterned graphene conductive film prepared in the embodiment was tested for conductivity, and the sheet resistance was 35kΩ / □, which has good conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com