Gearbox for a rail vehicle drive train

A rail vehicle and transmission technology, applied in the field of rail vehicles, can solve the problems of increasing transmission and spare parts manufacturing- and storage costs, limiting transmission applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

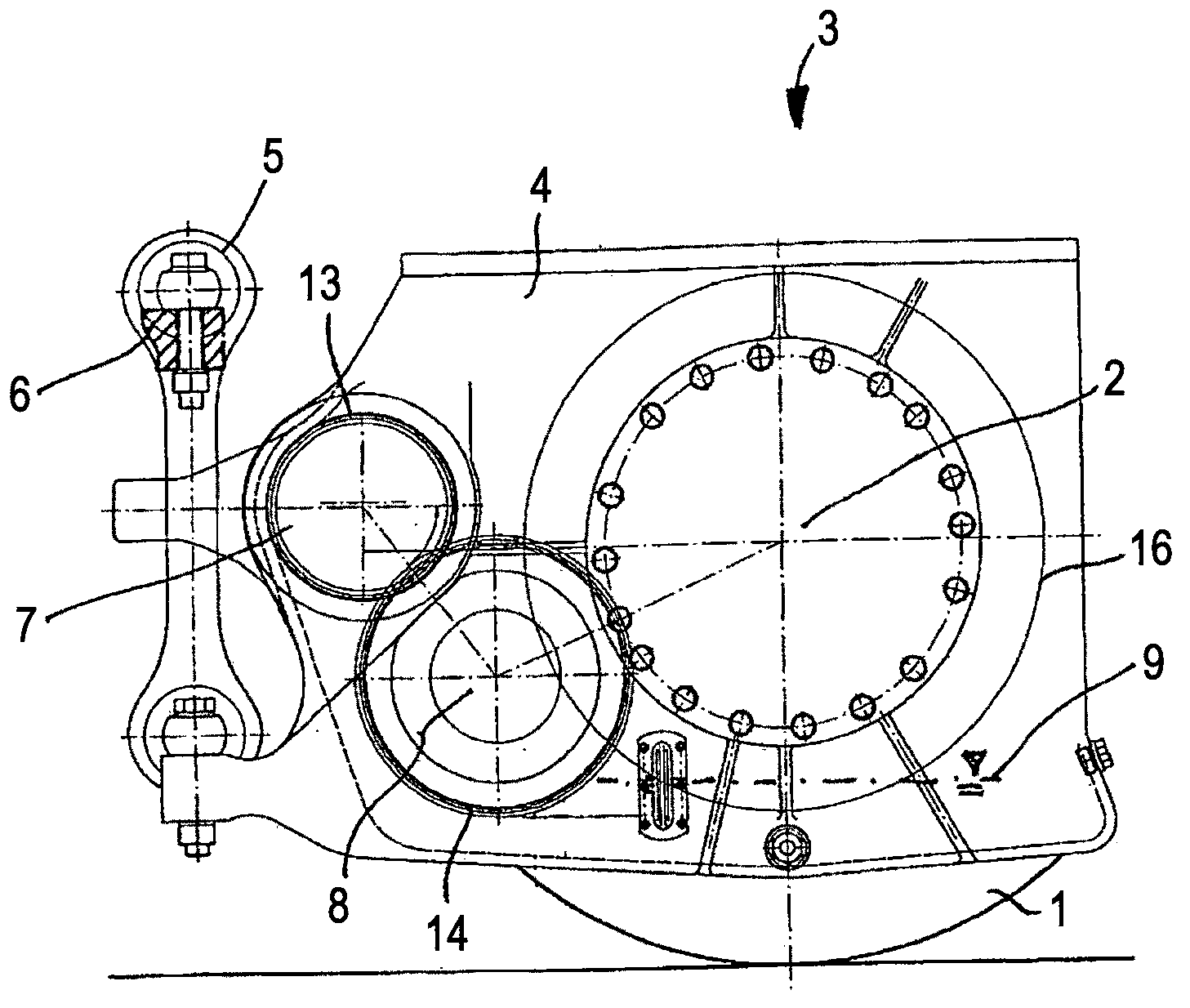

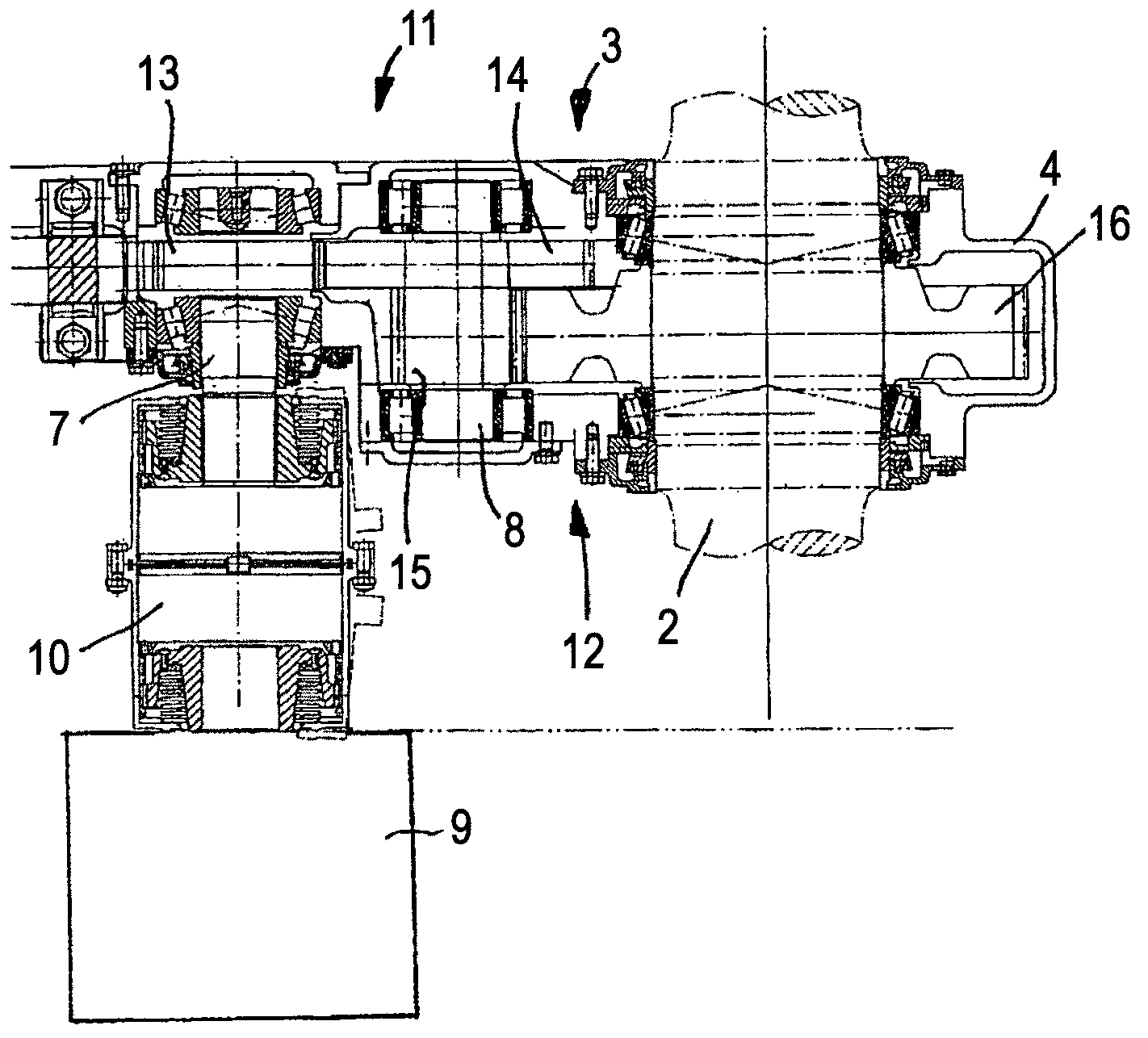

[0027] exist figure 1 A drive wheel 1 of a rail vehicle is shown in . Drive wheels 1 are supported by an output shaft 2 of a transmission 3 . The transmission 3 itself, including the transmission housing 4 , is mounted on the output shaft 2 and is supported against torsion by means of a torque bearing 5 on a bogie 6 (here only a small part is shown shaded).

[0028] drive engine (in figure 1 (not shown in ) is introduced into the transmission 3 through the input shaft 7 of the transmission 3 . The drive power is transmitted from the input shaft 7 to the output shaft 2 through the intermediate shaft 8 by means of two gear pairs, according to the following figure 2 Detail the gear pair.

[0029] In the transmission housing 4, an oil sump 9 is formed in the lower region, by means of which the transmission is lubricated and at least the driven gear 16 on the output shaft 2 and the gear on the intermediate shaft 8 meshing with it and the intermediate The gear wheel 14 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com