Calcium sulfate scale cleaning agent and preparation method thereof

A calcium sulfate scale and cleaning agent technology, applied in detergent compositions, chemical instruments and methods, non-surface active detergent compositions, etc., can solve incomplete cleaning, difficulty in heating and cleaning circulation loops, low scale removal rate, etc. problems, to achieve the effect of convenient cleaning operation, high removal rate and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

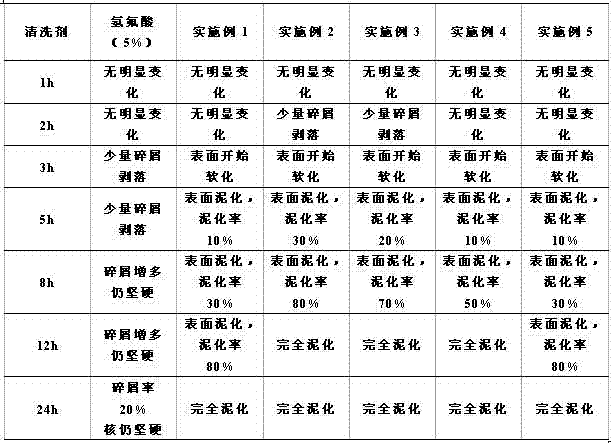

Examples

Embodiment 1

[0013] In 300g of water, add 100g of sodium humate, 50g of sodium hydroxyethylene diphosphonate, 5g of ethylenediaminetetraacetic acid, 5g of alkylphenol polyoxyethylene ether, and 5g of chlorinated-1,3-dialkylpyridine, Stirring was continued at 20°C for 3 hours until complete dissolution. Cooling and discharging, the calcium sulfate scale cleaning agent is obtained.

Embodiment 2

[0015] In 300kg of water, add sodium acetate 170kg, sodium hydroxyethylene diphosphonate 40kg, sodium ethylenediamine tetramethylene phosphonate 60kg, hexamethylenetetramine 8kg, polyethylene glycol 6kg, methacryloyl oxide Ethylammonium chloride 8kg was continuously stirred at 50°C for 3 hours until it was completely dissolved. Cooling and discharging, the calcium sulfate scale cleaning agent is obtained.

Embodiment 3

[0017] In 300kg of water, sequentially add 90kg of sodium sulfamate, 70kg of sodium glycolate, 60kg of sodium polyaspartate, 5.6kg of ammonium citrate, 6kg of polyethylene glycol, and 8kg of dodecyldimethylbenzyl ammonium chloride , and continued stirring at 30 °C for 3 hours until complete dissolution. Cooling and discharging, the calcium sulfate scale cleaning agent is obtained.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap