Unidirectional limitable hinged support for hinging pipe frame column foot and construction method of unidirectional limitable hinged support

A construction method and hinge support technology are applied in the field of independent movable pipe racks, which can solve the problems affecting the effectiveness of column hinges, poor rotatability of half hinges, and aging and hardening of elastic cushions, so as to avoid instability, connection and stability. Ease of assembly and reduced material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in combination with specific embodiments.

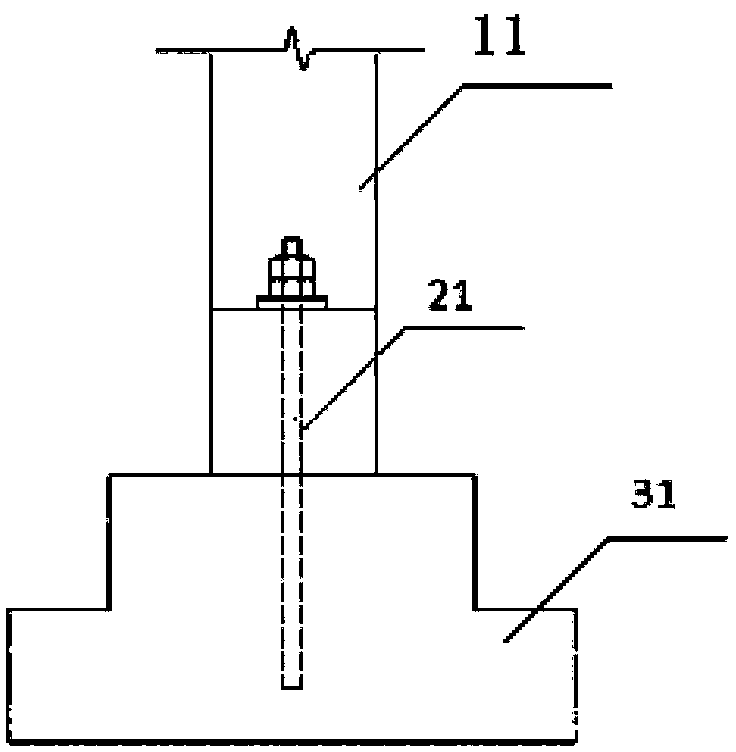

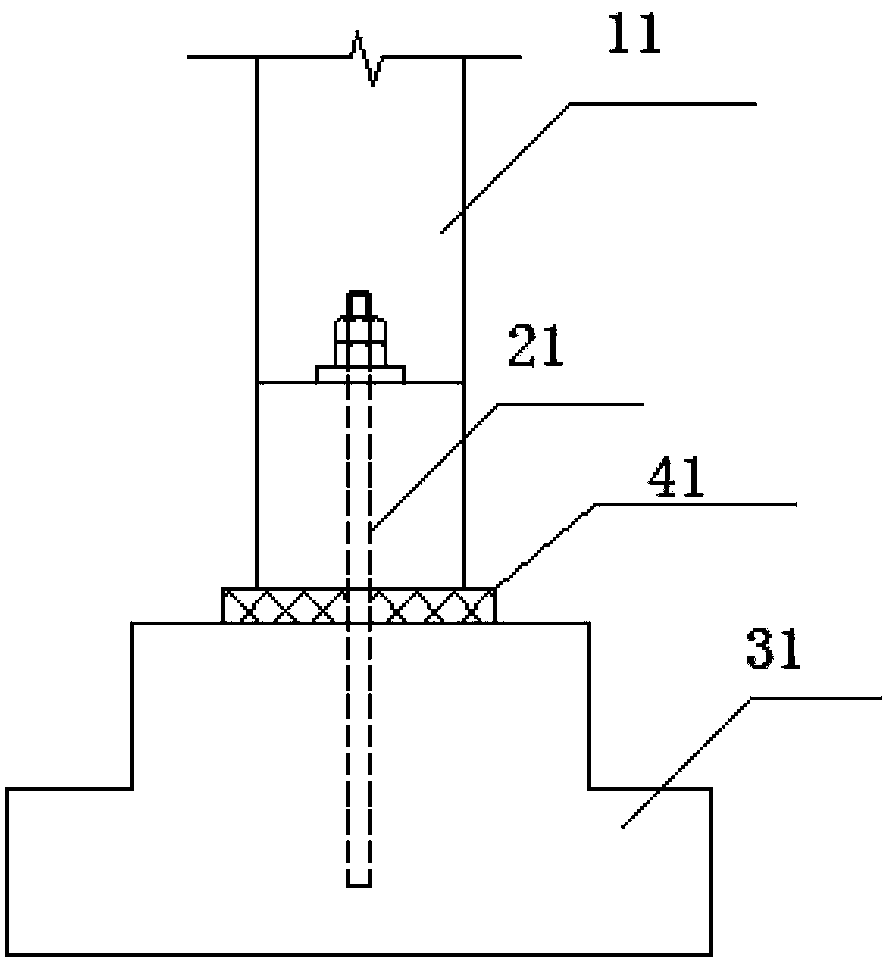

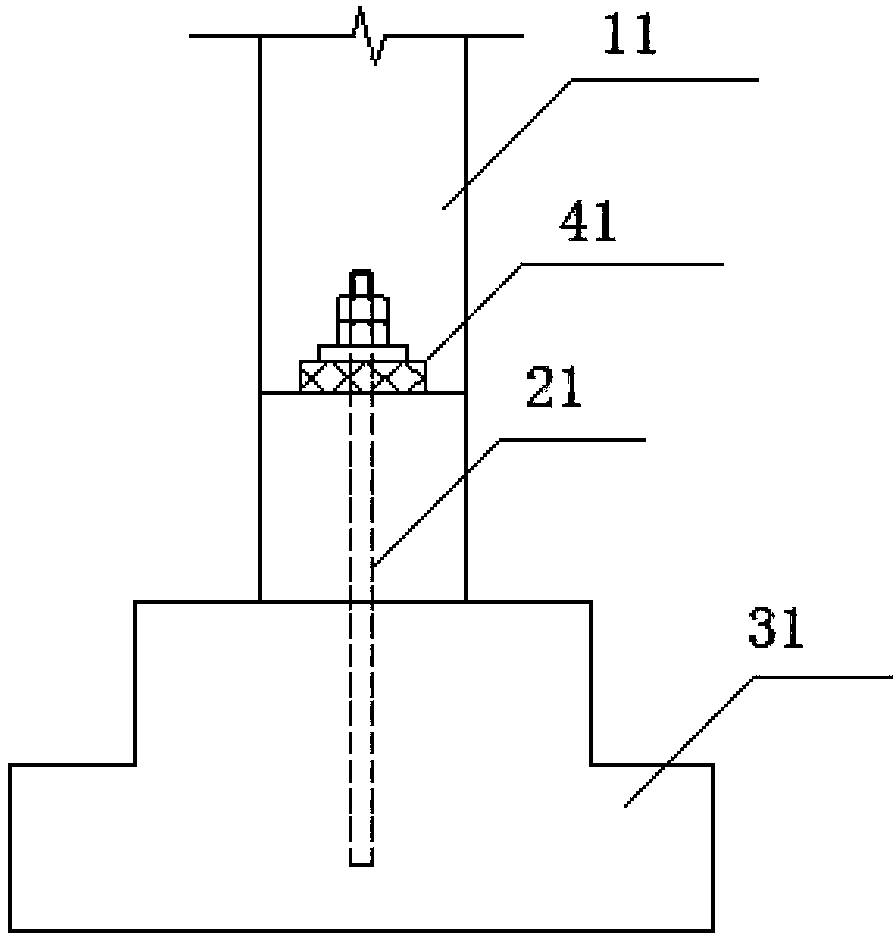

[0027] Image 6 It is a structural schematic diagram of the one-way limitable hinge support of the present invention, Figure 7 for Image 6 left view of , refer to Image 6 , 7 As shown, the one-way limitable hinge support used at the foot of the hinged pipe frame includes an upper structure and a lower structure, wherein the upper structure includes a hinge support top plate 2, a hinge support ear plate 3, a hinge support limit Position plate 4, hinge support top plate stiffener 7; hinge support ear plate 3, hinge support limit plate 4 are all welded to the bottom of hinge support top plate 2, and limit plate 4 is located in the middle of the bottom of hinge support top plate 2, Two hinge support ear plates 3 are symmetrically and parallelly arranged on both sides of the limit plate 4 (the ear plate 3 is longer than the limit plate 4), and the top plate stif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com