Construction method for hoisting engineering tube well stand pipe of high-rise building

A technology for high-rise buildings and construction methods, applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficult construction, hidden safety hazards, low construction efficiency, etc., to improve construction quality, improve construction progress, The effect of ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

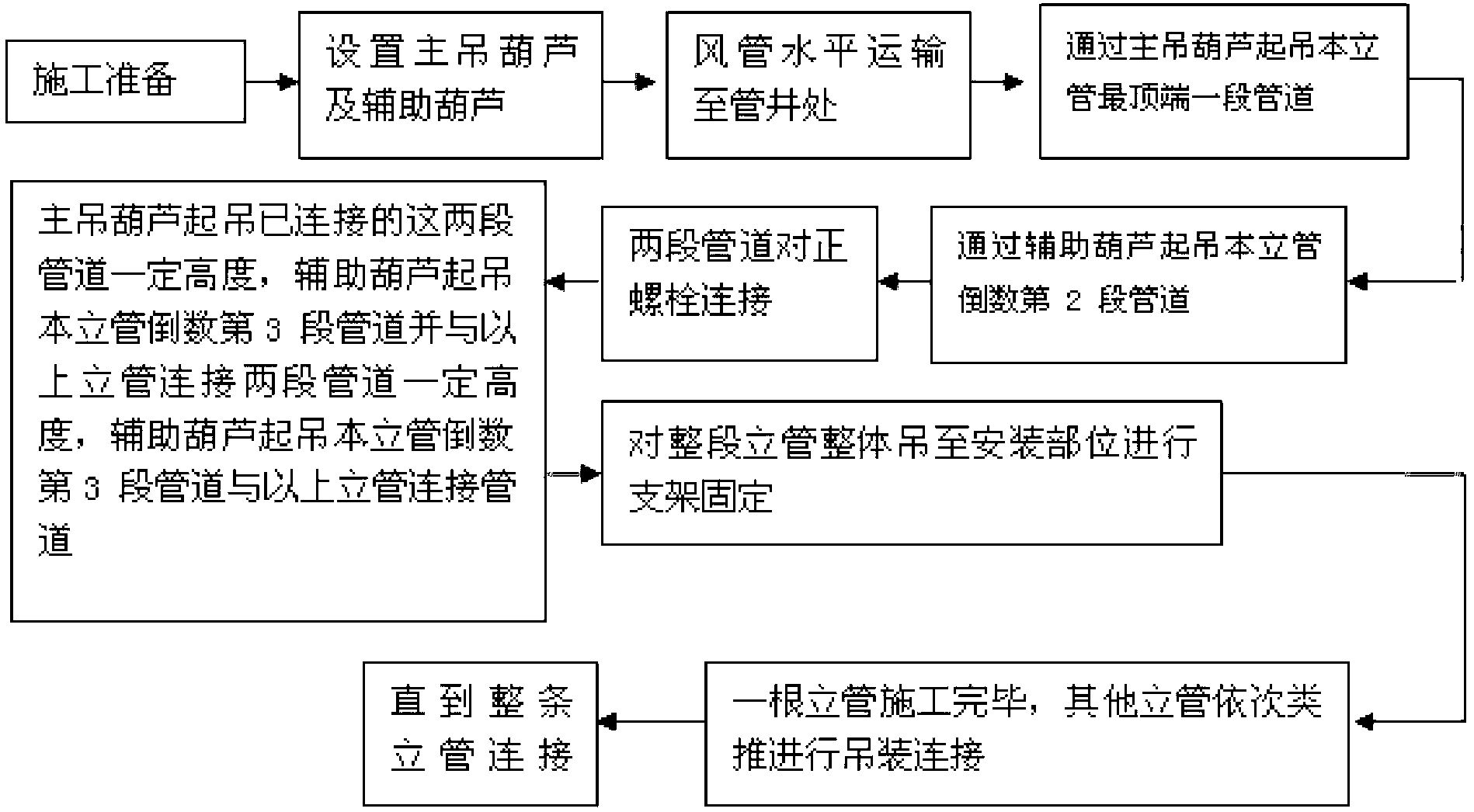

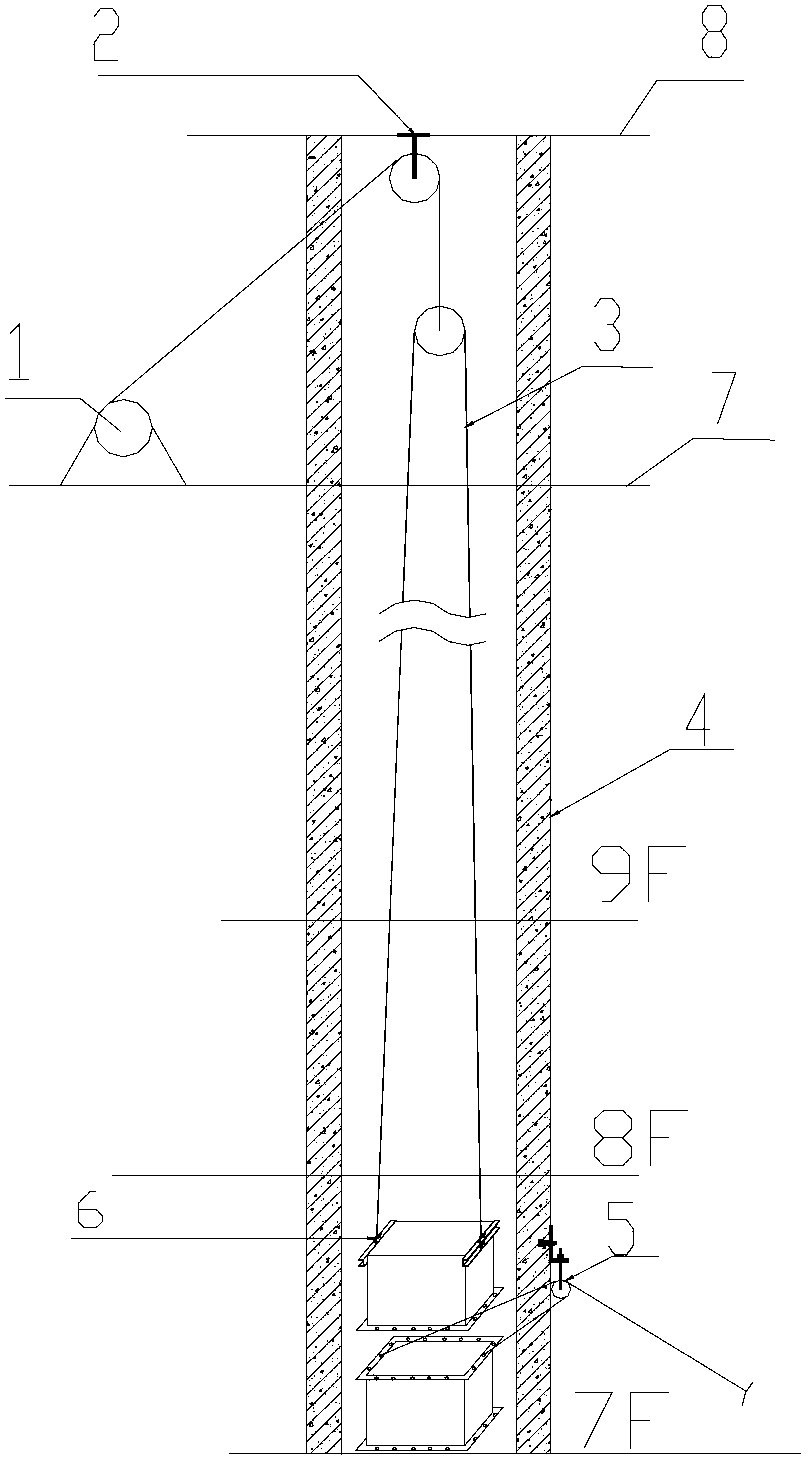

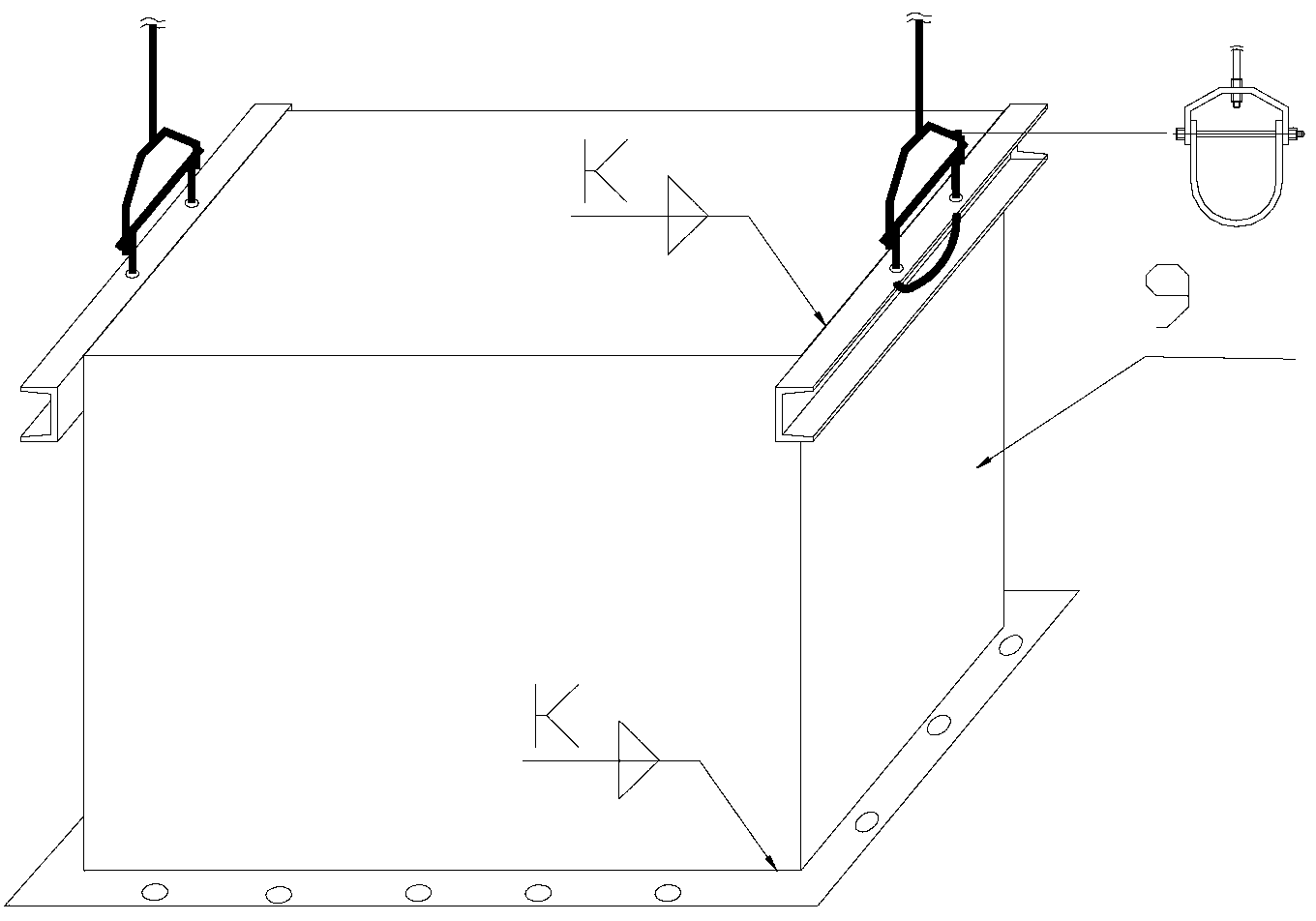

[0025] A construction method for hoisting a riser of a tube well in a high-rise building project provided by the invention comprises the following steps: (1), construction preparation; (2), setting a main hoist and an auxiliary hoist; (3), transporting the pipeline horizontally to the tube well; (4) The top section of the riser pipe is lifted by the main hoist; (5) The penultimate second section of the riser is lifted by the auxiliary hoist; (6) The two pipes are connected by alignment bolts; (7) The main hoist The hoist lifts the connected two sections of pipelines to a certain height, and the auxiliary hoist lifts the penultimate section of the riser pipe and connects the two sections of pipelines with the above standpipe to a certain height, and the auxiliary hoist lifts the penultimate section of the standpipe to connect the above standpipe (8), hoisting the entire section of the riser to the installation site for bracket fixing; (9), the construction of one riser is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com