Elastic structural elements with through-turn geometry

A technology of elastic structural parts and geometric shapes, which is applied in the direction of spring components, springs, and low internal friction springs composed of several springs, can solve the problems that the transition state is difficult to be uniform and coherent, and the rigid-flexible balance point is difficult to determine, etc., to achieve The effect of widening the range of materials used and the selection of a wide range of material mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

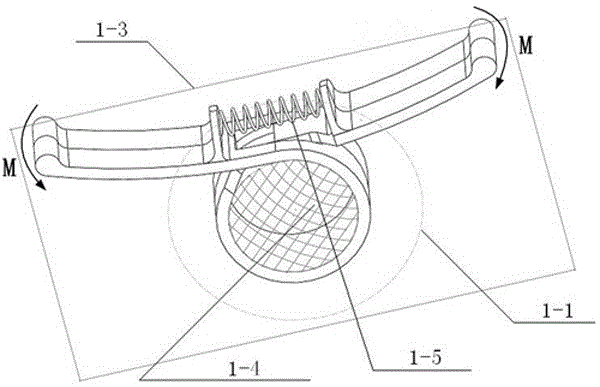

[0026] This embodiment is a kind of elastic structure with a single through-type rotary geometry, see figure 1 .

[0027] Through the pre-deformation storage in the dotted line range indicated in 1-1, the elastic capacity of the integrated material, especially the weak elastic capacity of the integrated rigid material, is used to obtain the elastic bending moment, and through the structure’s own traversal form, the structure moves within a limited space. The direction of elastic deformation of structural parts can be constrained, and the geometric displacement of structural parts can be controlled, so that the elastic bending moment M always acts on the symmetry plane 1-3 of the structure, ensuring that the stress-bearing state and elastic deformation of structural parts are in a stable state, and the load-bearing function be reliably achieved. Devices that redistribute the stress state of the elastic strain process, such as rubber, silicone rubber 1-4, spring 1-5, etc., can ...

Embodiment 2

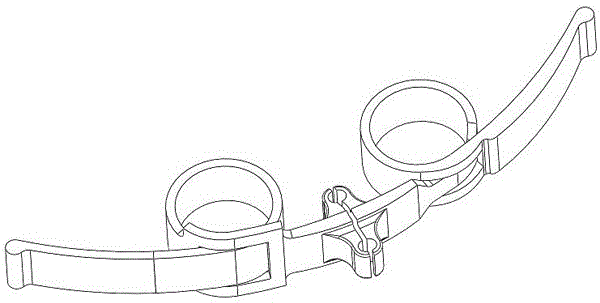

[0029] This embodiment is an elastic structural member with a continuous traversing rotary geometry to adapt or adjust the structural elastic capacity required for load bearing under different dynamic states (the process also includes the realization of both rigidity and flexibility and even rigid load bearing form) . see figure 2 .

Embodiment 3

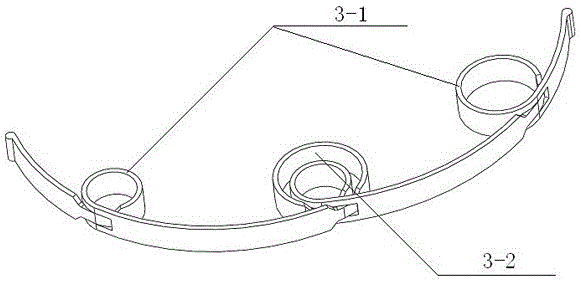

[0031] This embodiment is an elastic structural member with continuous and repeatable (such as 3-1) or helical (such as 3-2) traversing rotary geometry to adapt or adjust the load under different dynamic states. The required structural elasticity (the process also includes the ability to achieve both rigidity and flexibility and even a rigid load-bearing form). see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com