Curtain piece and production process thereof

A production process and technology of curtain sheet, applied in the field of curtain sheet and its production process, can solve problems such as poor strength and toughness, waste of wood, easy deformation, etc., and achieve performance improvement such as strength and toughness, broaden the scope, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

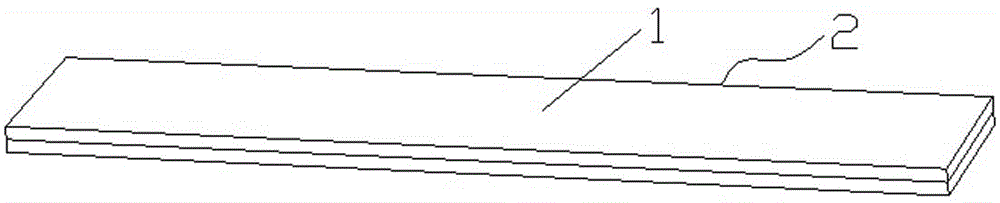

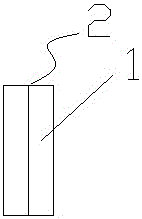

[0023] The curtain sheet of the present invention is composed of at least two veneer sheets 1 stacked and bonded to form a curtain sheet body 2, and at least two veneer sheets 1 are bonded and fixed on the surface.

[0024] Further, the above-mentioned curtain body is formed by laminating two veneers with a thickness of 0.8-2.5 mm, preferably with a thickness of 1.2-1.5 mm.

[0025] Further, in order to reduce the material waste caused by the sawing kerf, the above-mentioned thin wood chips are sliced by a wood planer to form a required thickness. The slicing method can make the surface smoothness after processing meet the requirements, and can greatly save the material waste caused by the sawing road.

[0026] Further, in order to reduce deformation, the veneers are heat-pressed, dried and shaped before being laminated.

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com