Screening and detecting method for ultrasonic water flow detection transducers

A detection method and water flow technology, applied in the direction of liquid/fluid solid measurement, instruments, measuring devices, etc., can solve the problems of uncontrolled long-term working characteristics, attenuation of characteristic indicators, and unpredictability, so as to improve measurement accuracy and work efficiency. Stability, ensuring long-term use reliability, and ensuring the effect of working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

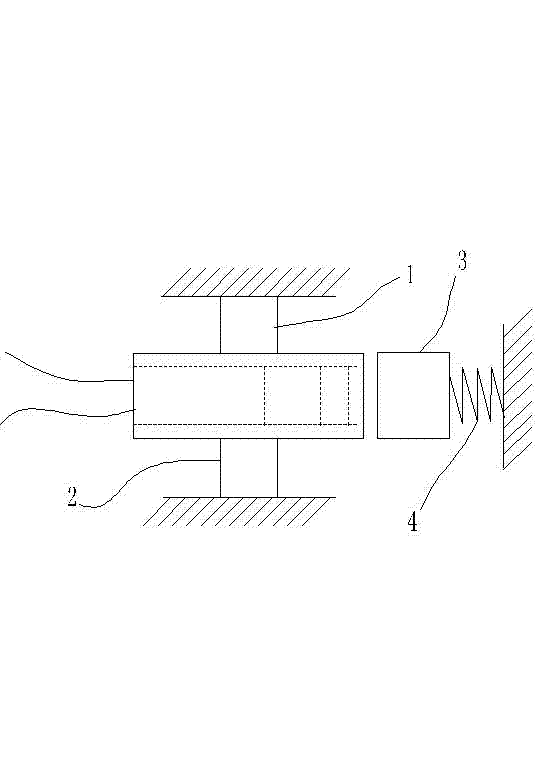

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] A screening detection method for ultrasonic water flow detection transducers, characterized in that it includes the following steps: 1) Pre-inspection of piezoelectric ceramic elements, and welding the two electrodes of the piezoelectric ceramic elements that pass the inspection to the upper electrode respectively lead-out wires, and short-circuit the two electrode lead-out wires; 2) put the piezoelectric ceramic element short-circuited by the electrode lead-out wires into a constant temperature box, and adjust the temperature in the box to the temperature of the Curie point of the piezoelectric ceramic element material. 50% to 60%, then keep warm for 3 to 5 hours, then let the temperature in the box drop to room temperature and cool down for 0.5 to 1 hour; 3) Repeat the above step 2 three to five times, take out the piezoelectr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com