Plane strain triaxial apparatus of axial rolling spacing board

A technology of plane strain and limit plate, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that cannot accurately reflect the plane strain stress conditions, etc., and achieve stable and reliable test results, reasonable design, and use The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

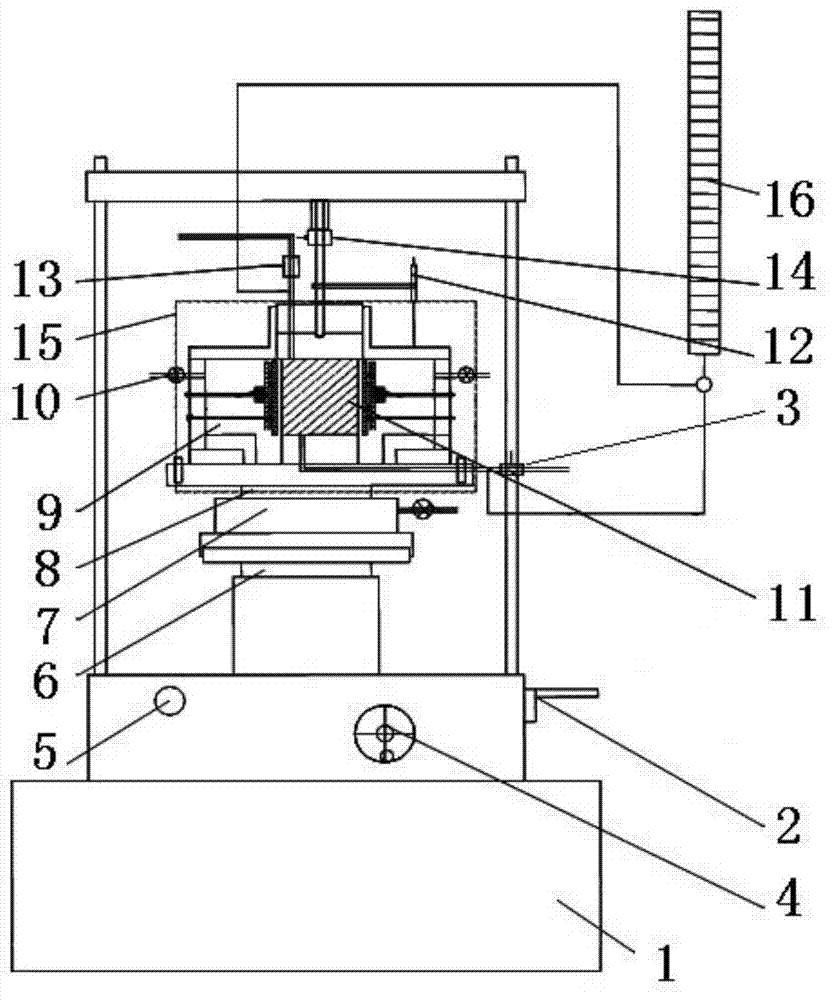

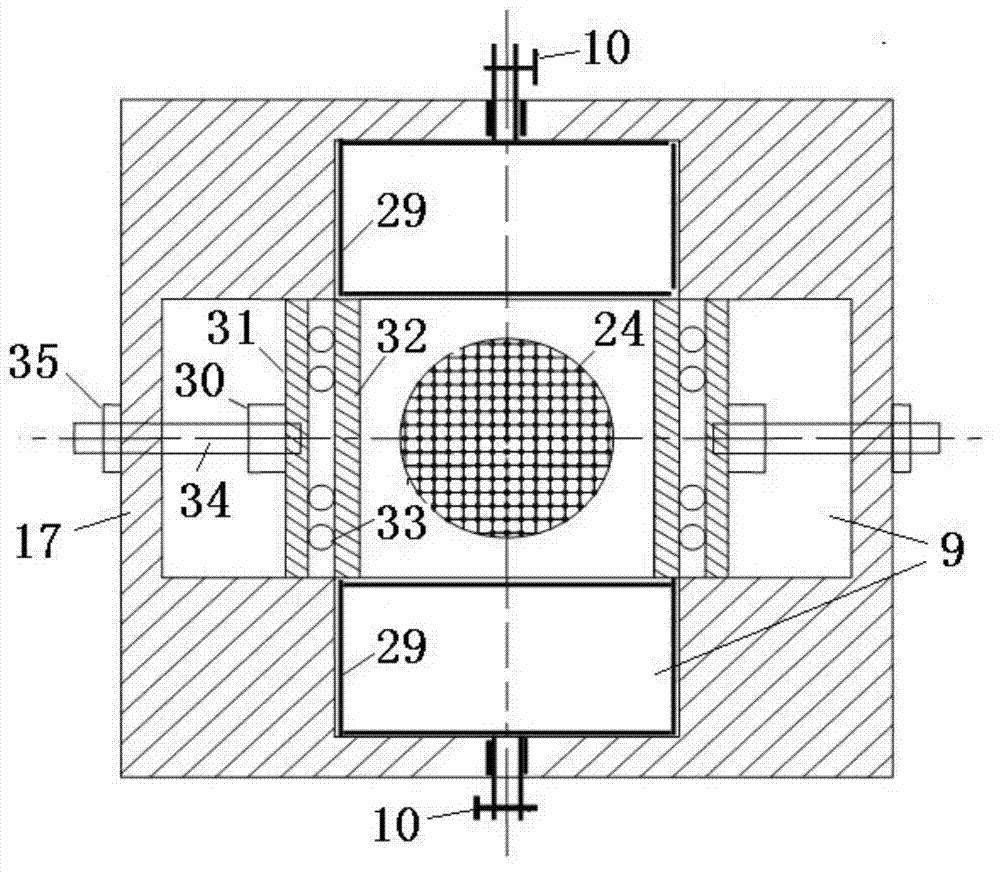

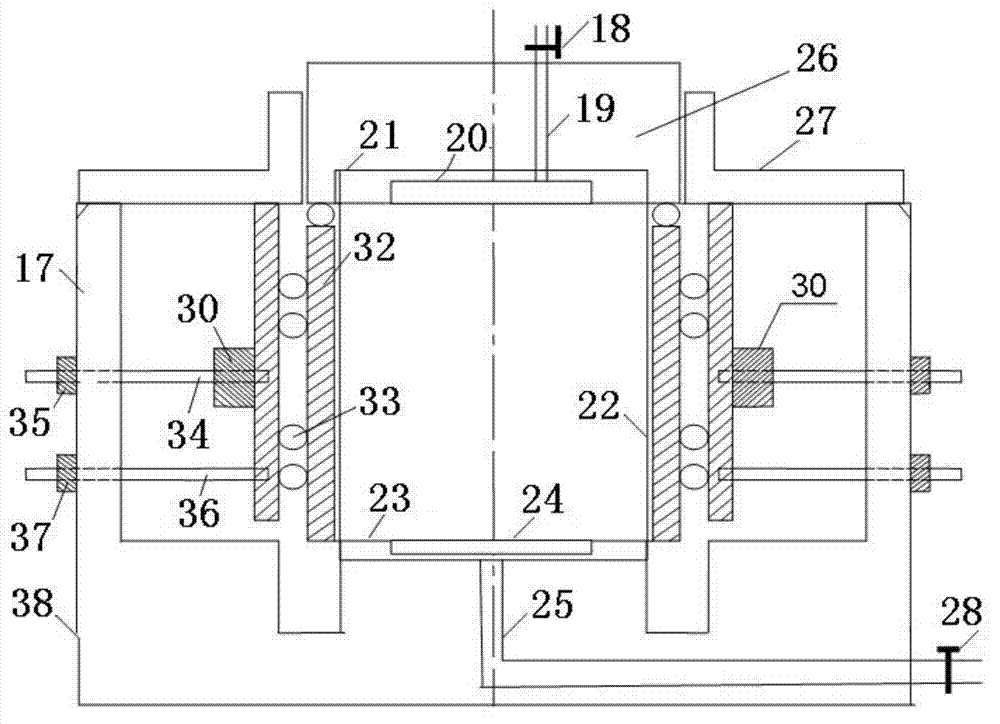

[0015] The plane strain triaxial instrument of the axial rolling limit plate of the present invention comprises three parts: a main machine part, a loading measurement mechanism, and an acquisition control mechanism. The host part mainly consists of a pressure chamber and a sample carrying device, which is the core to realize the stress application on the cube sample and the control of the drainage conditions. The loading measurement mechanism mainly realizes the stress loading, deformation control and measurement of the two principal stress directions, the large and small principal stress directions, as well as the stress measurement in the middle principal stress direction and the control of zero strain. The specific implementation mainly includes: the axial principal stress is changed by a A group of stepper motors drive the screw to push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com