Testing machine for head stack assembly piezoceramic micro-drive displacement

A piezoelectric ceramic and head stack assembly technology, which is applied in the field of piezoelectric ceramic micro-drive displacement testing machines for head stack assemblies, can solve the problems of inability to meet batch test requirements, failure to meet the pure mechanical swing dynamic characteristic test of a single head, etc. The effect of saving material cost, easy operation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

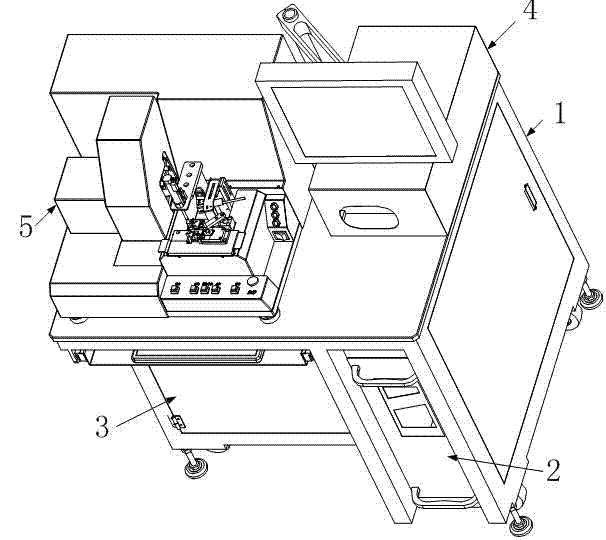

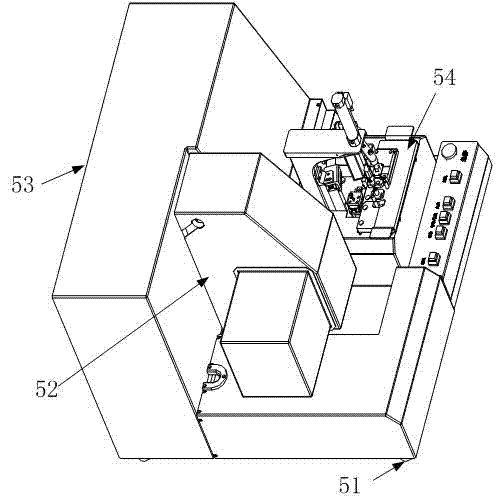

[0031] Such as figure 1 , figure 2 As shown, the piezoelectric ceramic micro-drive displacement testing machine for the head stack assembly includes a frame 1, a Doppler laser transmitter 3 and an industrial computer 2 are arranged in the frame 1, and a Doppler laser transmitter is installed on one side of the frame 1. The laser controller 4, the other side is provided with the hard disk head stack test main mechanism 5, the hard disk head stack test main body mechanism 5 is composed of a laser sensor probe positioning mechanism 52, a hard disk internal read and write drive frame clamping mechanism 54 and a test integrated support frame mechanism Composed of 53, the laser sensor probe positioning mechanism 52 and the hard disk internal read-write drive frame clamping mechanism 54 are installed on the test integrated support frame 53 mechanism, the hard disk head stack test main body 5 is placed on the rack 1 through the vibration isolation ring 51 .

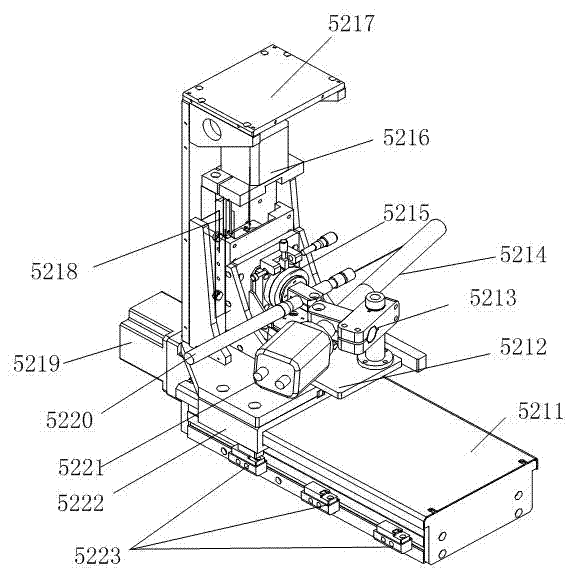

[0032] Such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com