Control circuit for constant temperature and constant temperature device

A technology of control circuit and constant temperature device, which is applied in the direction of using electric mode for temperature control, etc., can solve the problems of high energy consumption of the control coil, unbalanced effect, easy to be broken down, etc., and achieves low driving power and small electromagnetic interference. , the effect of reducing electromagnetic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

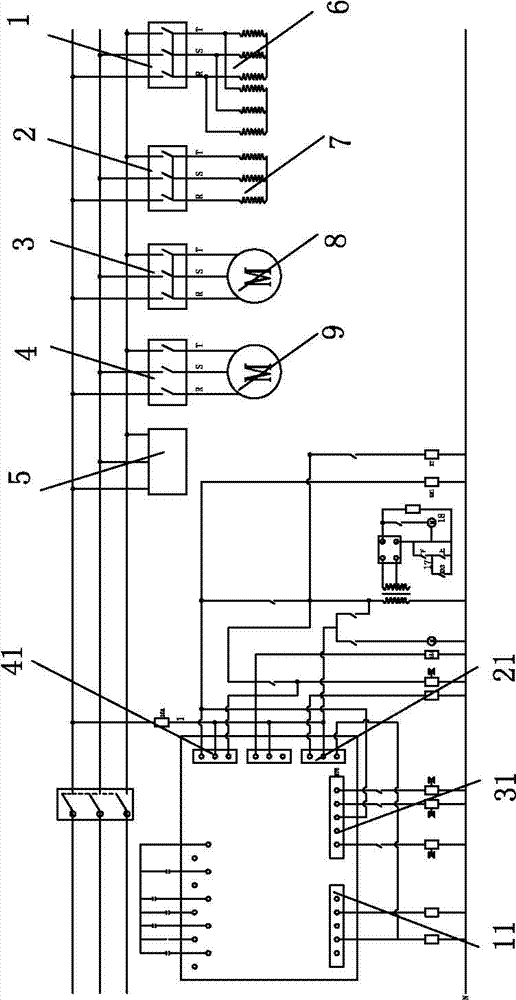

[0008] refer to figure 1 As shown, a control circuit for constant temperature and constant temperature devices is designed, and a control circuit board is provided. The control circuit board is provided with a primary refrigeration motor output control interface 41, a secondary refrigeration motor output control interface 31, and a heating device output control interface 21. . The output control interface 11 of the humidifying device, which also includes a primary cooling motor 9, a secondary cooling motor 8, a heating device 7, and a humidifying device 6 connected to the three-phase power supply through four solid state relays 1, 2, 3, and 4 respectively. The four solid state relays 1, 2, 3, and 4 of the first-stage refrigeration motor 9, the second-stage refrigeration motor 8, the heating device 7, and the humidification device 6 are respectively connected to the corresponding output interfaces 11, 21, 31, and 41 on the control circuit. connect.

[0009] In the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com