Shaft furnace fault condition forecasting method based on improved case-based reasoning

A case and fault technology, applied in the field of automation, can solve the problem of low fault prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

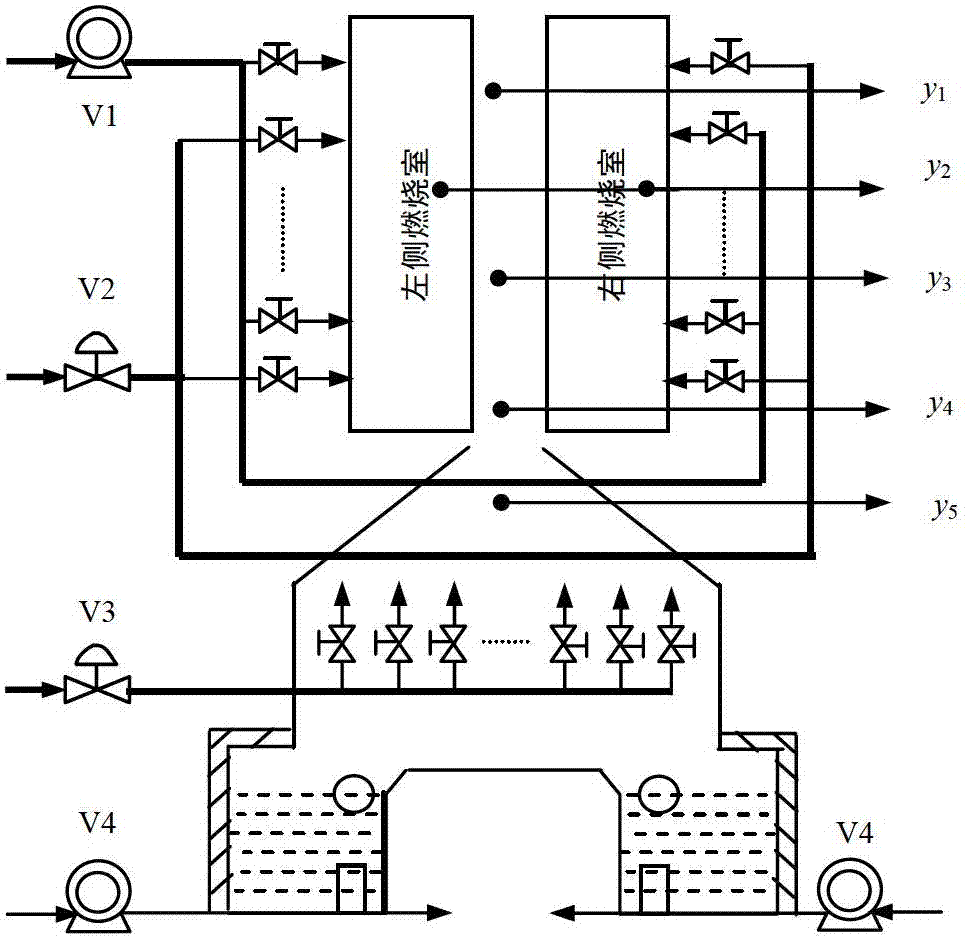

[0055] see figure 1 Shown is the schematic diagram of the shaft furnace roasting process and faults. Blower V 1 delivered air and regulating valve V 2 The transported gas is mixed and combusted in the combustion chambers on both sides, and the raw ore to be processed entering the furnace from the top of the shaft furnace is heated to 700-850°C, and the ore falls to the reduction zone and cools down to about 570°C, and is connected with the regulating valve V 3 The transported gas undergoes a reduction reaction to generate a strong magnetic roasted ore, and finally passes through the motor V 4 Move out of the oven. In the production process of the shaft furnace, there are 5 most common failures, which are burning y 1 , fire y 2 , blast y 3 , furnace y 4 and overreduction y 5 , these types of faults may occur simultaneou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com