Rotating multifunctional platform

A multi-functional, rotating technology, which can be used in the direction of tables whose desktop can rotate on the vertical axis, the combination of two or more pieces of different types of furniture, and tables with variable table heights, which can solve the problem of limiting activity space, taking Picking up items requires people to turn around or turn sideways, which is inconvenient, so as to increase the placement space, facilitate placing or picking up items, and avoid bending under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

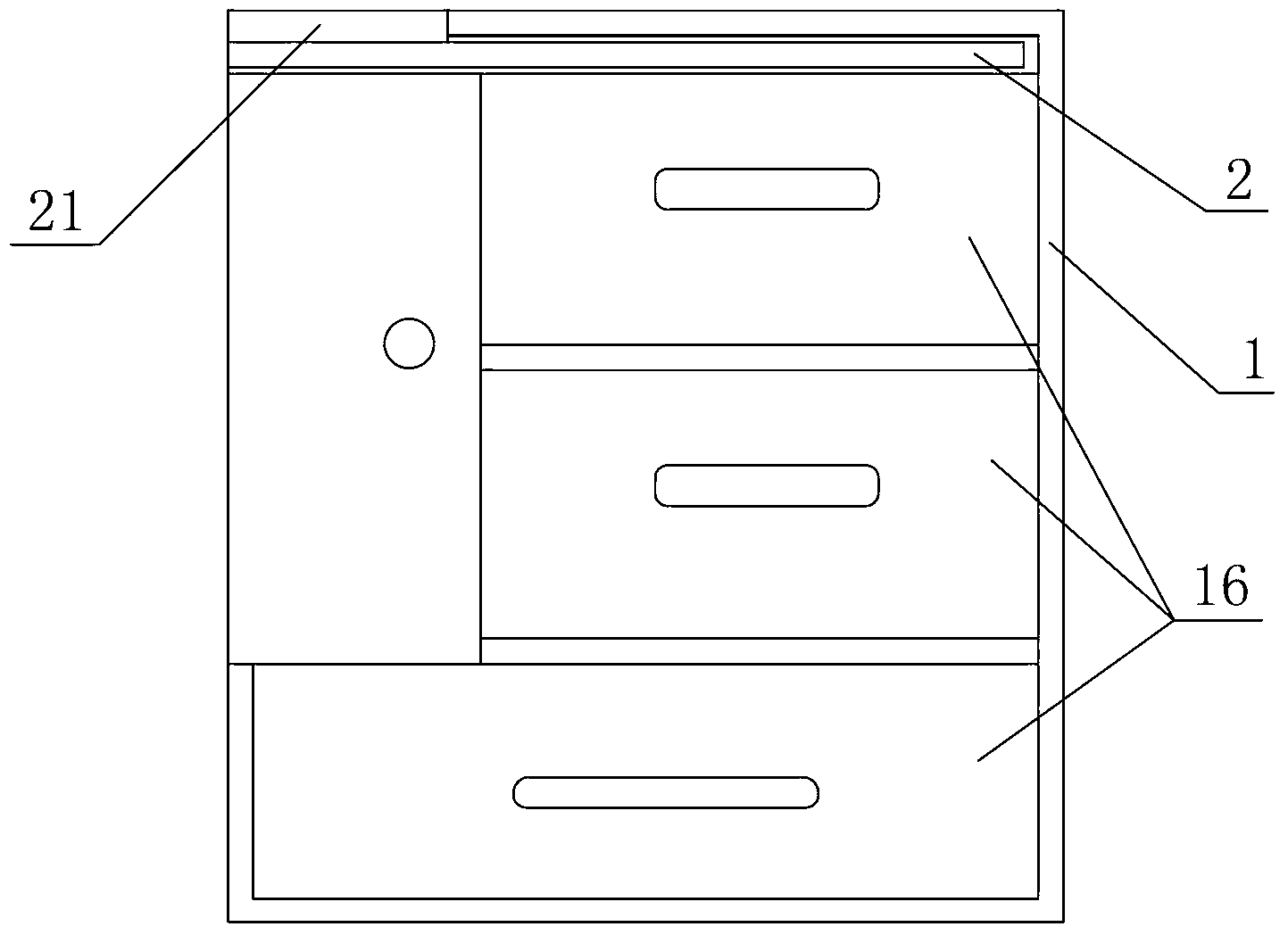

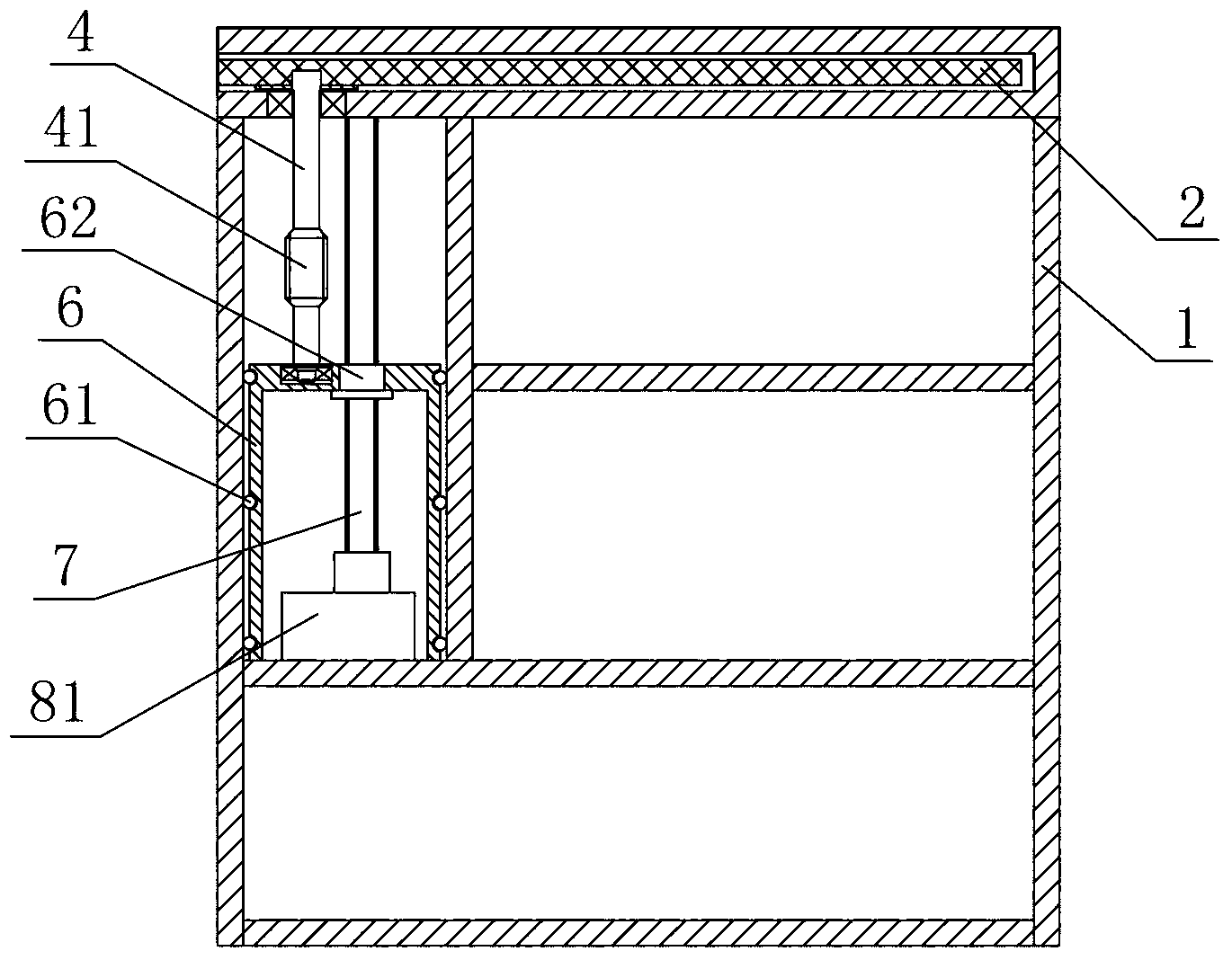

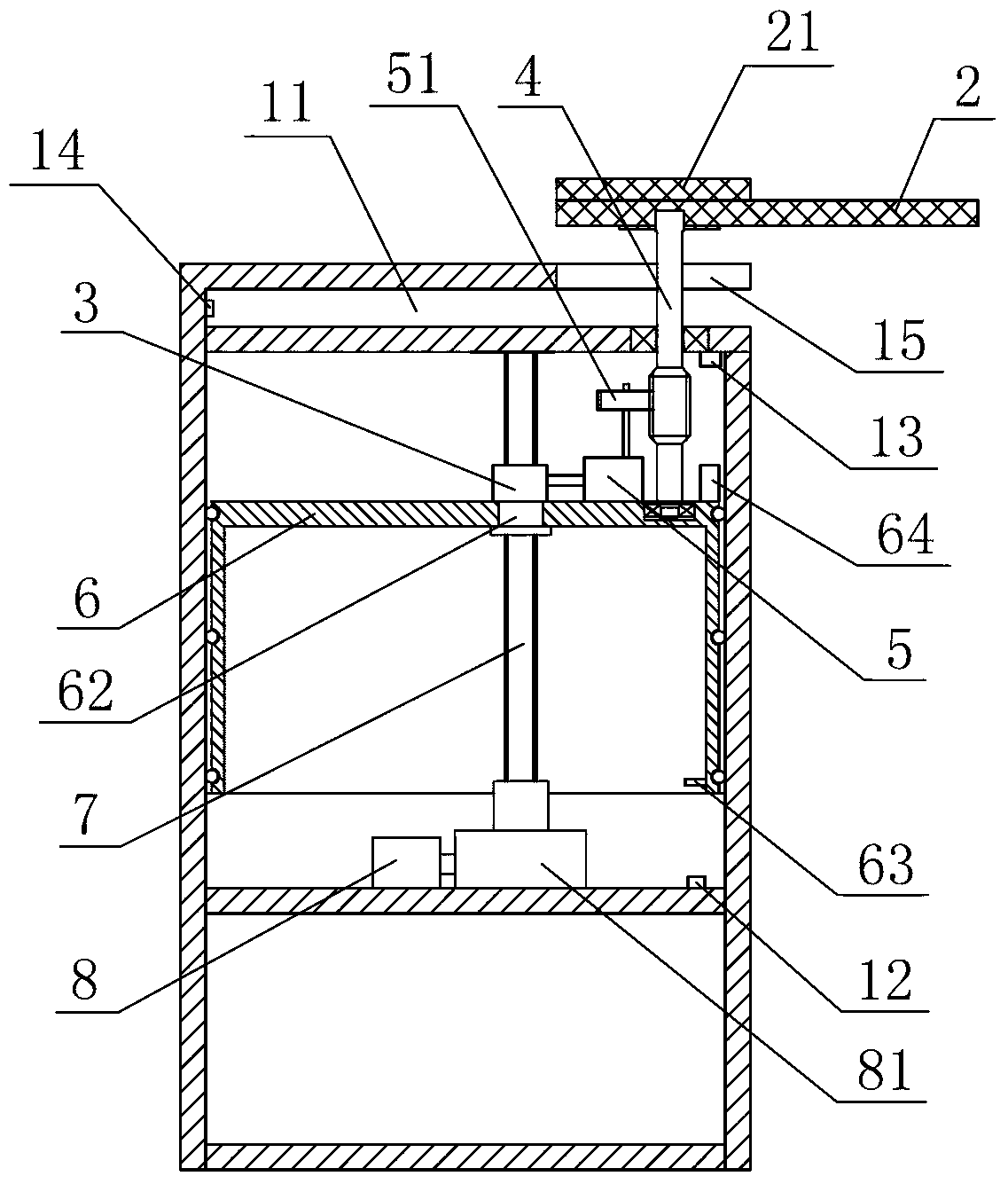

[0020] Embodiment 1: As shown in the figure, a rotary multifunctional platform includes a main body 1 and a rotating plate 2. The upper end of the main body 1 is provided with a cavity 11 with openings on both sides, and the rotating plate 2 is located in the cavity 11. The main body 1 is provided with a control system (not shown in the figure) and a rotating drive device for the rotating plate 2, and a lifting drive device. The rotating plate driving device includes a first motor 3, a rotating shaft 4 and a first reduction box assembly 5. The lifting drive device includes a lifting Platform 6, screw mandrel 7 and second motor 8, lifting platform 6 is arranged in the main body 1, the left and right sides of lifting platform 6 are connected with a plurality of rollers 61 respectively, the first motor 3 and the first reduction box assembly 5 are fixedly installed On the lifting platform 6, the rotating shaft 4 is connected to the lifting platform 6, the rotating plate 2 is fixedl...

Embodiment 2

[0021] Embodiment 2: As shown in the figure, other structures are the same as Embodiment 1. The difference is that the lifting drive device of the rotating plate 2 includes a lifting platform 6 and a second motor 8. The lifting platform 6 is arranged in the main body 1, and the first motor 3 and the first reduction box assembly 5 are fixedly installed on the lifting platform 6, the rotating shaft 4 is axially connected to the lifting platform 6, the second motor 8 is fixedly installed in the main body 1, and the drive shaft of the second motor 8 is coaxially fixed with a drive Bevel gear 82, the main body 1 is provided with a coaxial driven bevel gear 83 and a driving spur gear 84, the driving bevel gear 82 is meshed with the driven bevel gear 83, the main body 1 is connected with a driven spur gear 85, and the driving The spur gear 84 is meshed with the driven spur gear 85, and the lifting platform 6 is integrally provided with a rack 63, the driven spur gear 85 is meshed with...

Embodiment 3

[0022] Embodiment 3: As shown in the figure, other structures are the same as Embodiment 1. The difference is that an auxiliary rotating plate 9 and an auxiliary rotating shaft 91 are also provided. The auxiliary rotating plate 9 is located in the cavity 11 and below the rotating plate 2. An auxiliary lifting platform 92 is fixedly arranged on the table 6, the auxiliary rotating shaft 91 is axially connected to the auxiliary lifting platform 92 and coaxially sleeved on the rotating shaft 4, and a third motor 93 and a third reduction box assembly 94 are fixedly arranged on the auxiliary lifting platform 92 , the drive shaft of the third motor 93 is fixedly connected to the input shaft of the third reduction box assembly 94, the output shaft of the third reduction box assembly 94 is coaxially fixed with an auxiliary worm gear 95, and the auxiliary shaft 91 is coaxially fixed with an auxiliary The worm 96, the auxiliary worm gear 95 and the auxiliary worm 96 are meshed, and the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com