Pipe bending device

A pipe bender and pipe bending technology, which is applied in the field of pipe benders, can solve problems such as easy bending and cracking, and wrinkles in bending parts, and achieve the effects of enhanced performance, reasonable structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

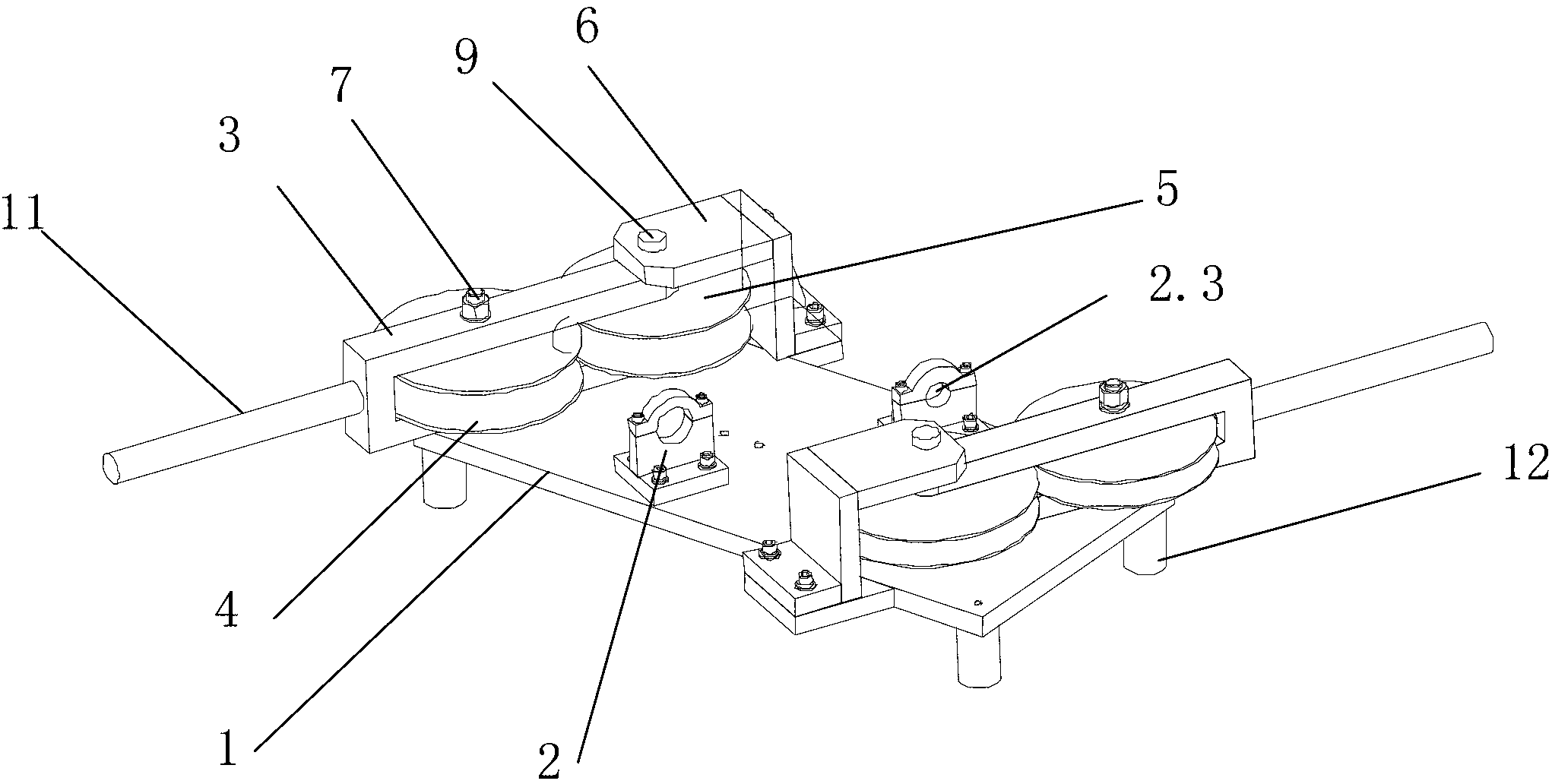

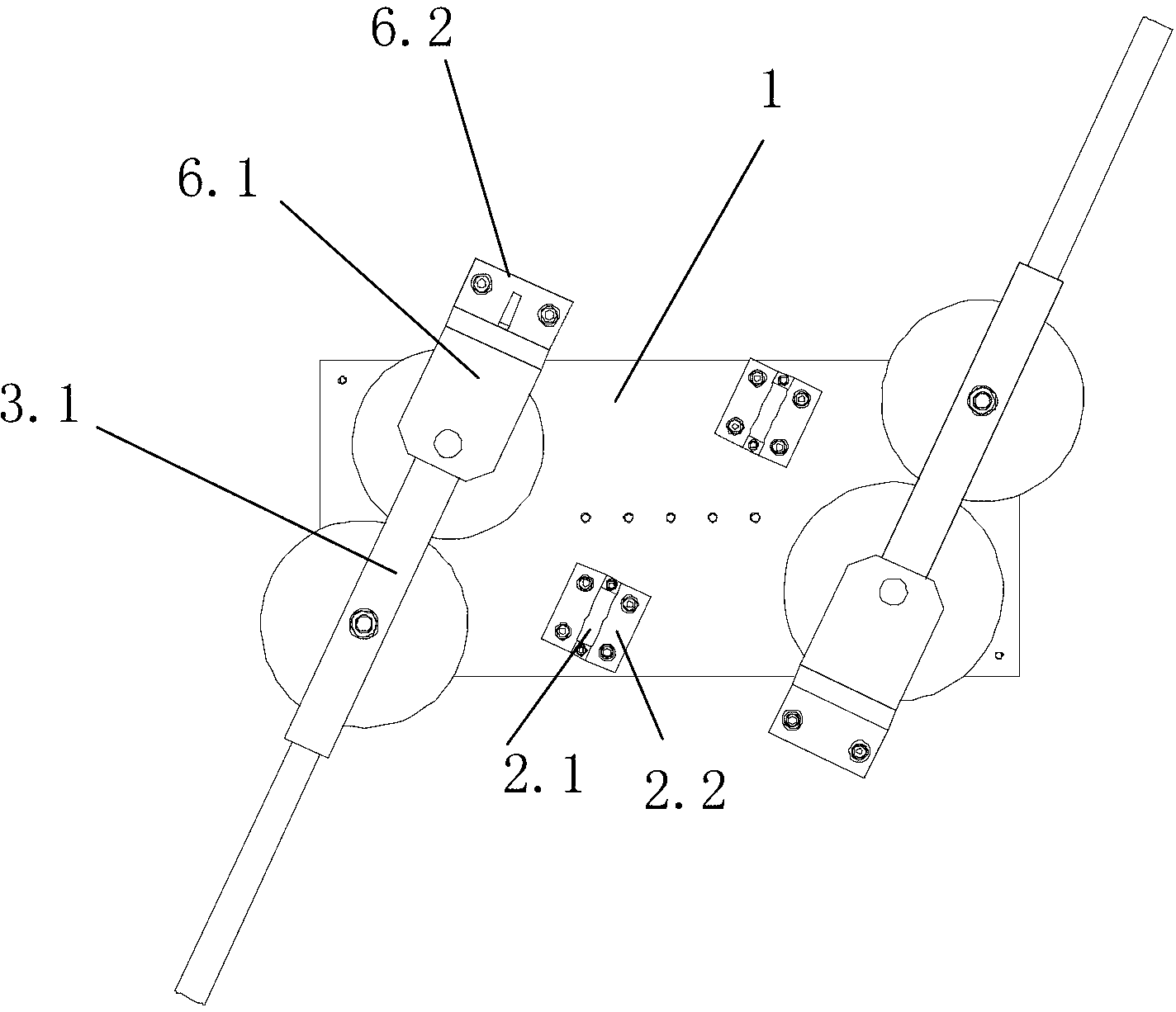

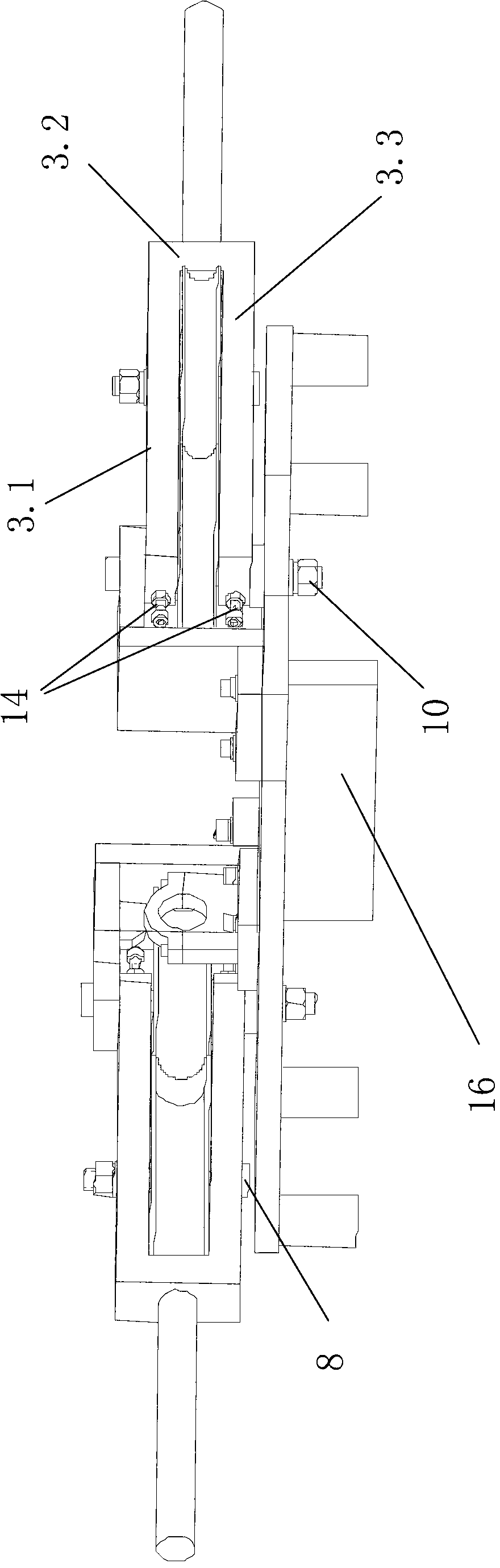

[0027] like Figure 1-6 The shown pipe bender of the present invention includes a workbench 1, a fixing base 2 fixed on the workbench and a pipe bend assembly; the pipe bend assembly includes a horizontal U-shaped connector 3, a The first roller 4 and the second roller 5 arranged horizontally in the inner cavity; the U-shaped connector is composed of an upper plate 3.1, a bottom plate 3.2 and a lower plate 3.3 connected in sequence; between the first roller and the second roller there is a The gap through which the bent stainless steel pipe passes; one end of the first roller is close to the bottom plate of the U-shaped connector; one end of the handle 11 is inserted into the U-shaped connector through the through hole of the bottom plate and pressed against the outer surface of the first roller; the reinforcement plate 6 is a zigzag plate, which is set at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com