Automatic wire bending machine

A wire bending machine and automatic technology, which is applied in the field of automatic wire bending machines, can solve the problems of low flexibility, multiple molds, etc. in the initial stage, and achieve reliable and accurate positioning, clean cross-section, and avoid the effect of wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

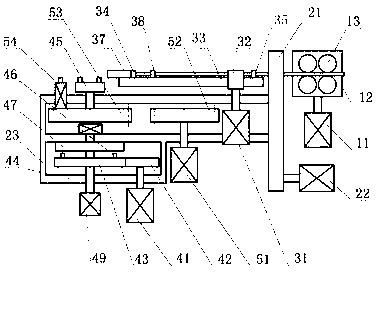

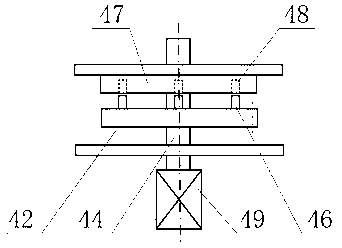

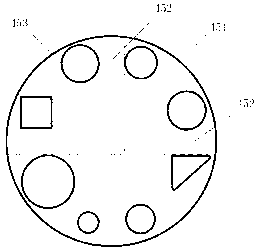

[0024] An automatic wire bending machine mainly includes several major mechanisms including a feeding mechanism 1, a rotating mechanism 2, a shearing mechanism 3, a die changing mechanism 4, and a bending mechanism 5.

[0025] Feeding mechanism 1 is mainly used for conveying the metal wire rod 10 that is used to manufacture spring, and feeding mechanism mainly comprises feeding motor 11, feeding device 12, has wire feeding wheel 13 on the feeding device 12, and feeding motor 11 drives wire feeding wheel 13 to rotate, and metal The wire 10 is placed between the wire feeding wheels 13 , and the metal wire 10 is driven to be transported forward by the rotation of the wire feeding wheels 13 .

[0026] The rotating mechanism 2 is a rotating part, which carries the mold changing mechanism 3, the bending mechanism 4 and the shearing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com