Special drilling and reaming equipment for distributor of air conditioning system

A technology of air-conditioning system and special equipment, applied in other manufacturing equipment/tools, manufacturing tools and other directions, can solve the problems of complex production process, low production efficiency, troublesome operation, etc., and achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

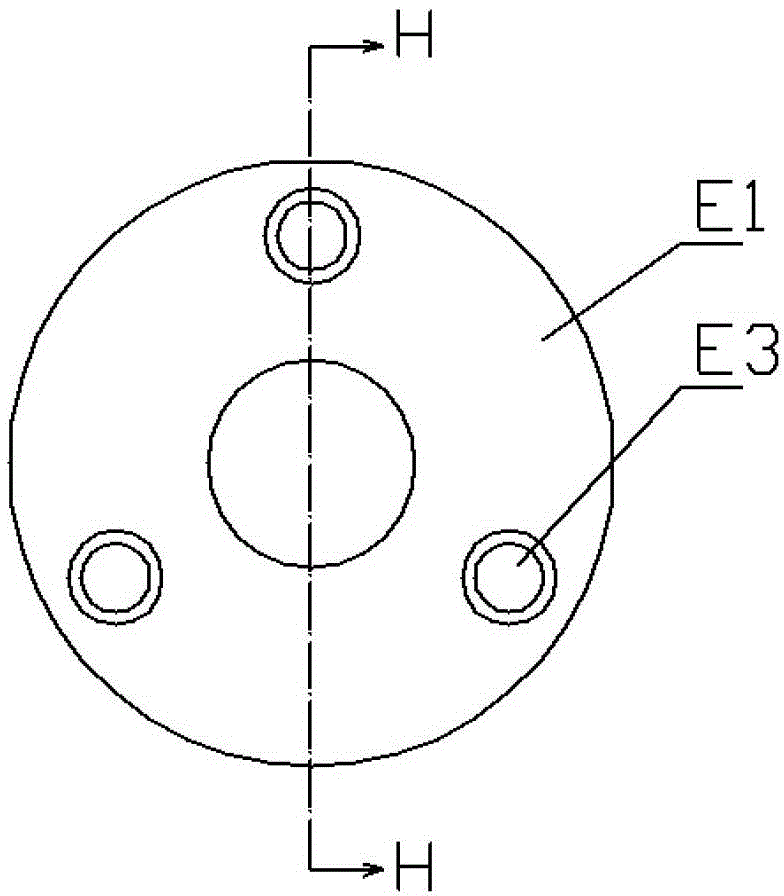

Image

Examples

Embodiment 1

[0030] Example 1: see Figure 5 As shown in -10, the special equipment for drilling and reaming of distributors for air-conditioning systems includes a horizontal motor 1 and a vertical motor 2, a horizontal linear guide rail 5 is fixed on the frame 4, and a horizontal slide plate 6 is inserted and sleeved on the horizontal linear guide rail 5. The transverse nut 7 is fixed on the transverse slide plate 6, the transverse screw rod 8 is screwed on the transverse nut 7, the transverse screw mandrel 8 is hinged on the frame 4, and the transverse motor 1 drives the transverse screw mandrel 8 to rotate through the wedge wheel and the synchronous belt;

[0031] A longitudinal linear guide rail (9) is fixed on the horizontal slide plate (6), the longitudinal slide plate (10) is inserted and sleeved on the longitudinal linear guide rail (9), the longitudinal nut (11) is fixed on the longitudinal slide plate (10), and the longitudinal screw rod ( 12) Screwed on the longitudinal nut (11...

Embodiment 2

[0034] Example 2, see Figure 11 As shown, the structure of the drilling and reaming device is that the main motor 3 is fixed on the longitudinal slide plate 10, the lower section hole drill bit clamp 13 is fixed on the rotating shaft of the main motor 3, and the lower section hole drill bit 13a is fixed on the lower section hole drill bit clamp 13; Driving gear 14 is fixed on the rotating shaft, and first driven gear 15 is meshed with driving gear 14, and upper segment hole drill clip is fixed on the first driven gear 15 rotating shaft, and upper segment hole drill bit 15a is fixed on the upper segment hole drill clip, the first segment hole drill bit 15a is fixed on the upper segment hole drill clip, On the rotating shaft of two main motors 28, a reamer bit clamp is fixed, and a reamer bit 16a is fixed on the reamer bit clamp. All the other are with embodiment 1.

Embodiment 3

[0035] Example 3, see Figure 12 As shown, the support rod (29) is fixed on the described longitudinal slide plate (10), the support plate (30) is fixed on the support rod (29), and the second drill hinge device (C) is fixed on the support plate (30), A support rod (29) is fixed on the chuck seat (17), and a second chuck device (D) is fixed on the support plate (30);

[0036] The structure of the second drill-hinge device C is that the main motor 3 is fixed on the support plate 30, and the remaining parts have the same structure as the drill-hinge device A; the second chuck device D has the same structure as the chuck device B. All the other are with embodiment 1.

[0037] How it works: see Figure 5As shown, the blank F1 is clamped on the chuck 20, the drilling and reaming device A can move horizontally and vertically, the chuck device B is fixed on the frame 4 through the chuck seat 17, and can be adjusted by adjusting the waist bar hole 171 and adjusting The relative pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com