Fermentation method for lactobacillus with high cell density

A technology of lactic acid bacteria fermentation and lactic acid bacteria, which is applied in the field of lactic acid bacteria fermentation with high cell density, can solve the problems of high cost of lactic acid bacteria products, high cost of lactic acid bacteria, and long fermentation time, so as to improve product quality, increase the number of viable bacteria, and prepare simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

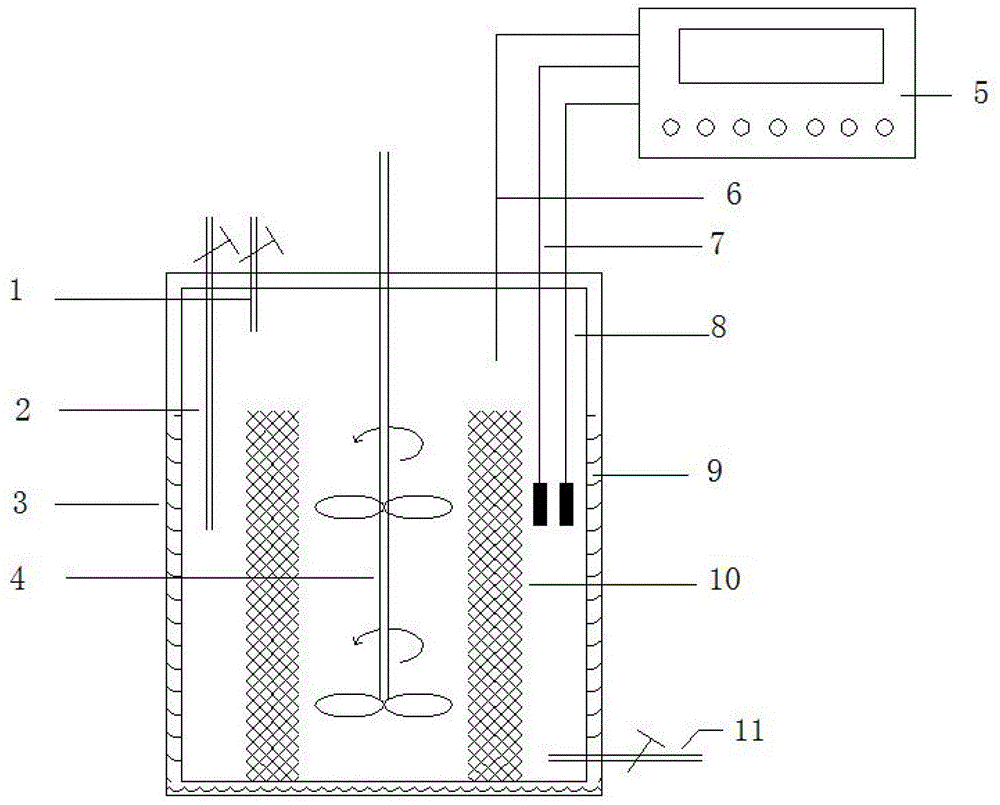

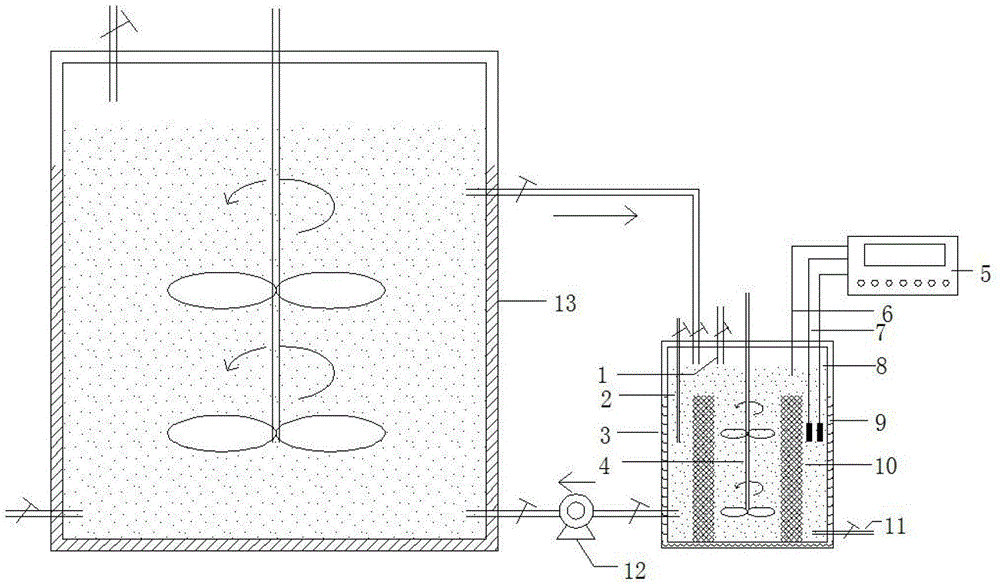

[0030] S1. Construct fiber bed reactor; figure 1 shown. attached figure 1 A structural schematic diagram of a fiber bed reactor is provided, including a reactor body 3, a heating device 9 is provided outside the reactor body 3, and a feed port 1, a sampling port 2, and an acid-base feed are provided at the upper end of the reactor body 3 System 6, the lower end of the reactor main body 3 is provided with a discharge port 11, a fiber material 10 is fixed inside the reactor main body 3, a stirring device 4, a pH electrode 7, a temperature electrode 8 are arranged inside the reactor main body 3, and an acid-base feeding system 6 , pH electrode 7 and temperature electrode 8 are connected with the control system 5, and the pH and temperature can be fed back to the control system 5 in real time, and the automatic control is realized through the acid-base feeding system 6 and the heating system 9.

[0031] The medium described in S2 is: 3% hydrolyzed whey protein (g / L) (food grade)...

Embodiment 2

[0037] S1. Build fiber bed reactor; Same as Example 1;

[0038] The medium described in S2 is: 3% hydrolyzed whey protein (g / L) (food grade), 2-2.5% glucose (g / L), 0.5-1% magnesium sulfate heptahydrate (g / L) , 10% corn steep liquor (ml / L), distilled water to a volume of 1L to prepare a culture medium, add it to the fiber bed reactor, and sterilize at 121°C for 15-20 minutes before use;

[0039] S3. Into the culture medium, insert Lactobacillus bulgaricus and Streptococcus thermophilus seed liquid activated by the MRS liquid medium, and the inoculation amount is 3% and 3% of the total volume of the culture medium respectively;

[0040] S4. Adjust the temperature to 37°C, adjust the pH value to 6.5, carry out fermentation culture, and regularly take samples to detect the number of bacteria;

[0041] S5. When the number of bacteria reaches 10 10 Stop fermentation when cfu / ml is above. All the fermentation broth is discharged from the outlet and collected for downstream process...

Embodiment 3

[0044] S1. Build fiber bed reactor; Same as Example 1;

[0045] The medium described in S2 is: 3% hydrolyzed whey protein (g / L) (food grade), 2-2.5% glucose (g / L), 0.5-1% magnesium sulfate heptahydrate (g / L) , 10% corn steep liquor (ml / L), distilled water to a volume of 1L to prepare a culture medium, add it to the fiber bed reactor, and sterilize at 121°C for 15-20 minutes before use;

[0046] S3. Insert the seed solution of Lactobacillus acidophilus, Lactobacillus bulgaricus and Streptococcus thermophilus activated by the MRS liquid medium into the culture medium, and the inoculum amount is 2%, 2% and 2% of the total volume of the culture medium respectively;

[0047] S4. Adjust the temperature to 37°C, adjust the pH value to 6.4, carry out fermentation culture, and regularly take samples to detect the number of bacteria;

[0048] S5. When the number of bacteria reaches 10 10 Stop fermentation when cfu / ml is above. All the fermentation broth is discharged from the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com