Preparation method of sulfone bridge type synthetic tanning agent

The technology of tanning agent and sulfone bridge is applied in the field of preparation of sulfone bridge type synthetic tanning agent, which can solve the problems of many by-products and poor application effect, and achieve the effects of fullness of finished leather, reduced extensibility and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

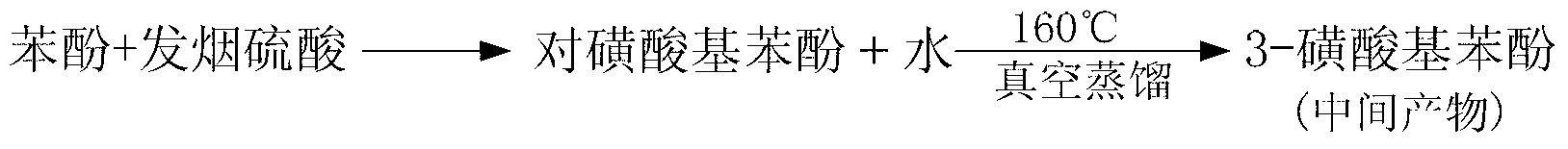

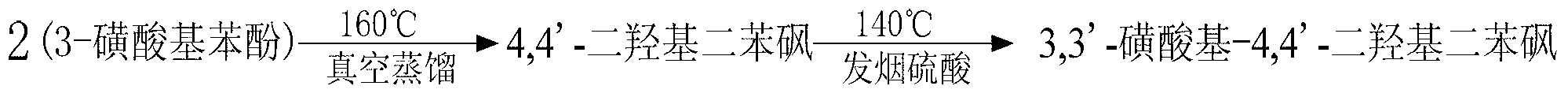

Method used

Image

Examples

Embodiment 1

[0035] Add 1000g of phenol into the reactor, then slowly drop 500L of 70% fuming sulfuric acid into the reactor, the dropping rate is about 10L / min, and the temperature in the reactor is 100°C. After the dropwise addition, the temperature was kept for 10 minutes to obtain the first reaction solution in which the main product was p-sulfonic acid phenol, and the first sample was taken as the first sample.

[0036] Test the titer rate of the first sample: Titrate the first sample with NaOH with a concentration of 1mol / g to a pH value of 3.5, and the consumption of 5.1-5.3mL NaOH is qualified.

[0037] The first reaction solution was subjected to vacuum distillation for 4 hours, and the distillation was stopped when the temperature was 150°C, the vacuum degree was 20-30 mmHg, and the distillate was removed to obtain the second product whose main product was 4,4'-dihydroxydiphenylsulfone. Second reaction solution. When the distillation reaches 3.5 hours, the second sample is taken...

Embodiment 2

[0043] Add 1400g of phenol into the reactor, then slowly add 700L of oleum with a concentration of 60% into the reactor dropwise, the dropping rate is about 30L / min, and the temperature in the reactor is 150°C. After the dropwise addition, the temperature was kept for 20 minutes to obtain the first reaction liquid whose main product was p-sulfonic acid phenol, and the first sample was taken as the first sample.

[0044] Test the titer rate of the first sample: Titrate the first sample with NaOH with a concentration of 1mol / g to a pH value of 3.5, and the consumption of 5.1-5.3mL NaOH is qualified.

[0045] The first reaction liquid was subjected to vacuum distillation for 5 hours, and the distillation was stopped when the temperature was 170°C, the vacuum degree was 20-30 mmHg, and the distillate was removed to obtain the second product whose main product was 4,4'-dihydroxydiphenylsulfone. Second reaction solution. When the distillation reaches 4.5 hours, the second sample is...

Embodiment 3

[0051]Add 1200g of phenol into the reactor, then slowly add 609L of oleum with a concentration of 20% into the reactor dropwise, the dropping rate is about 20L / min, and the temperature in the reactor is 160°C. After the dropwise addition, keep warm for 15 minutes to obtain the first reaction solution whose main product is p-sulfonic acid phenol, and take a sample for the first time, which is the first sample.

[0052] Test the titer rate of the first sample: Titrate the first sample with NaOH with a concentration of 1mol / g to a pH value of 3.5, and the consumption of 5.1-5.3mL NaOH is qualified.

[0053] The first reaction solution was subjected to vacuum distillation for 4 hours, and the distillation was stopped when the temperature was 160 ° C. The vacuum degree was 20-30 mm Hg, and the fraction was removed to obtain the second product whose main product was 4,4'-dihydroxydiphenyl sulfone. Second reaction solution. When the distillation reaches 3.5 hours, the second sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com