Front-wheel drive control system for tire-type paver anti-skid

A front-wheel drive and control system technology, applied in electric speed/acceleration control, road, road repair and other directions, can solve the problems of the influence of the life of the front wheel motor and the high design cost, achieve power saving, low cost, and prevent slippage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

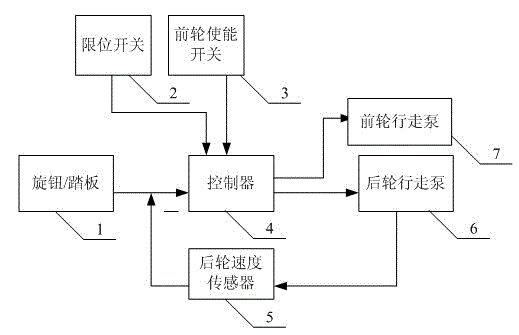

[0016] The present invention mainly comprises:

[0017] The controller is used to identify and process the signal output by the knob / pedal, select and process the input signal according to the instruction of the function switch, and output the working state instruction for controlling the front wheel walking pump and the rear wheel walking pump;

[0018] Rear wheel speed sensor: used to detect the walking speed of the rear wheel and feed it back to the controller.

[0019] Described function switch comprises:

[0020] Limit switch: output limit signal, limit whether the controller receives the knob signal or the pedal signal as the given signal.

[0021] Front wheel enable switch: output the front wheel working signal, and limit the controller to simultaneously output and control the front wheel walking work command and the rear wheel walking work command, so as to realize the front wheel auxiliary drive of the paver.

[0022] After the controller detects the front wheel ena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com