An auxiliary high-pressure water jet slit blowout prevention device

A high-pressure water jet and blowout prevention device technology, which is applied in safety devices, boreholes/well components, mining equipment, etc., can solve problems such as blowout holes, achieve the effects of preventing blowout holes, eliminating potential safety hazards, and avoiding life threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

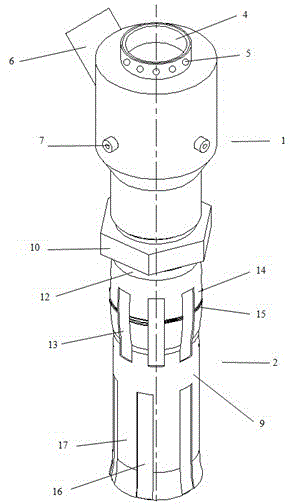

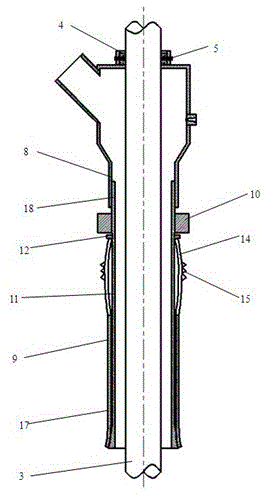

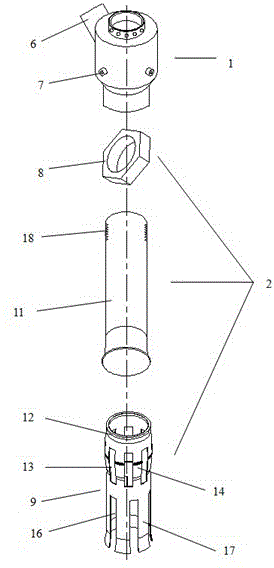

[0017] Below in conjunction with accompanying drawing, the present invention is further described: as Figure 1-3 As shown, an auxiliary high-pressure water jet slit blowout prevention device includes a gathering assembly 1 and a locking assembly 2, and the gathering assembly 1 and the locking assembly 2 are connected by threads; the locking assembly 2 includes an outer casing Sleeve 9, nut 10 and inner sleeve 11, the outer surface of the inner sleeve 11 is in smooth contact with the inner surface of the outer sleeve 9, the nut 10 is arranged on the inner sleeve 11, located between the outer sleeve 9 and the gathering Between component 1.

[0018] The top outlet of the collecting assembly 1 is provided with a sealing ring 4 with a screw 5, and the inner diameter of the sealing ring 4 is slightly larger than the outer diameter of the drill pipe used for drilling; The axis of 6 forms an acute angle with the axis of the main body of the collecting assembly 1; three atomizing noz...

Embodiment 2

[0024] There are 6 rectangular grooves 13, which are used to make the drum-shaped cylinder wall 14 bend upward when the nut is tightened.

[0025] There are 8 rectangular openings 16, which are used to make the bracket 17 open and be stuck in the drilled hole when the nut is tightened.

[0026] All the other technical features are the same as those in Embodiment 1.

Embodiment 3

[0028] There are 10 rectangular grooves 13, which are used to make the drum wall 14 bend upward when the nut is tightened.

[0029] There are four rectangular openings 16, which are used to make the bracket 17 open and be stuck in the drilled hole when the nut is tightened.

[0030] All the other technical features are the same as those in Embodiment 1.

[0031] The present invention is achieved like this:

[0032] 1. Insert the inner sleeve 11 from the bottom of the outer sleeve 9. Due to the horn-shaped opening at the lower part of the inner sleeve 11, the inner sleeve 11 can no longer move up relative to the outer sleeve 9 without applying a large force. ;

[0033] 2. Install the nut 10 on the male thread 18 on the upper end of the inner sleeve 11;

[0034] 3. Insert the assembled part into the drill hole and put it on the drill pipe 3, rotate the nut 10 and press the outer sleeve 9, because the inner sleeve 11 moves up relative to the outer sleeve 9, the drum shape of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com