Engine retarder

A retarder and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor reliability and complex structure, and achieve the effect of high retardation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

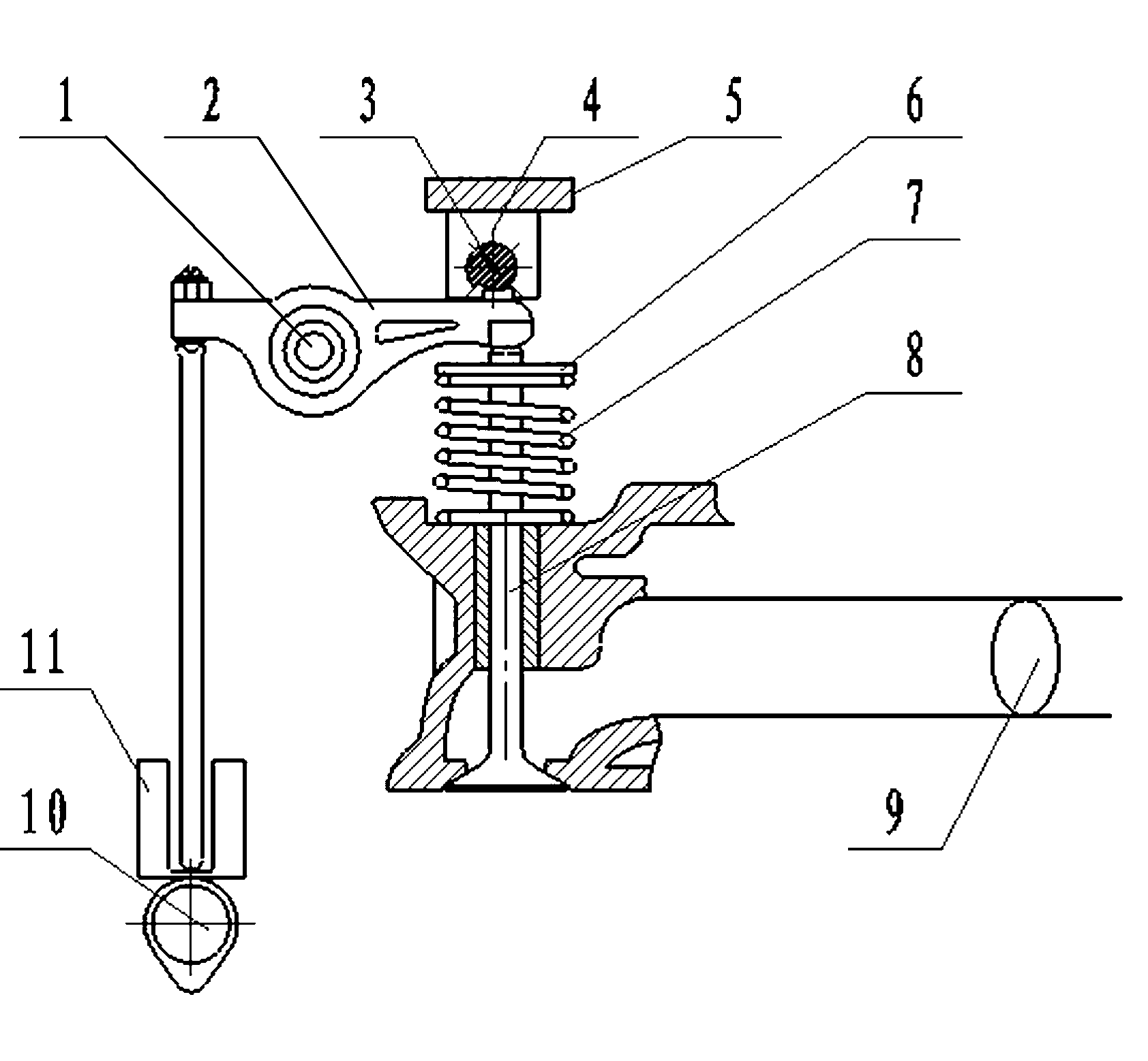

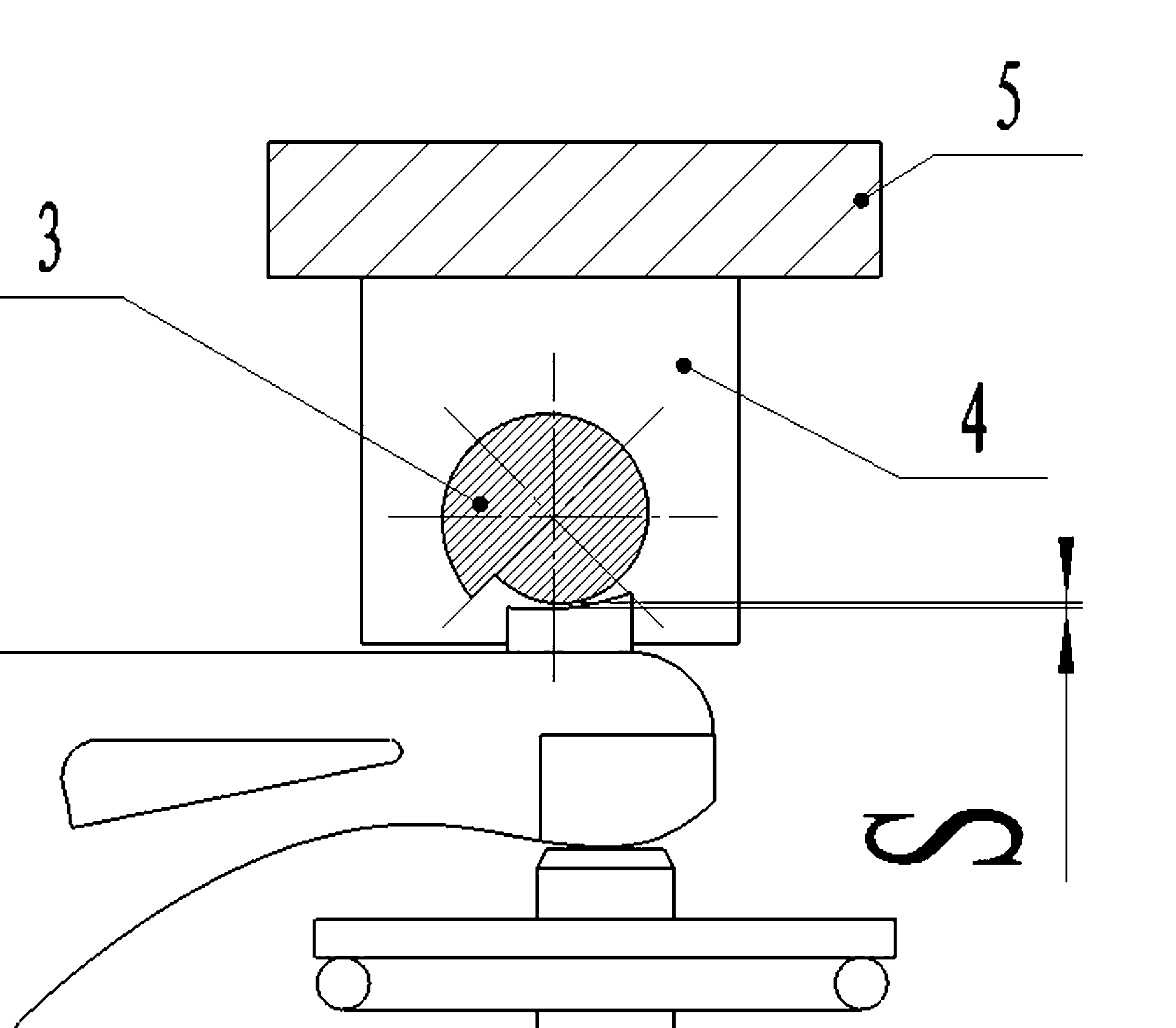

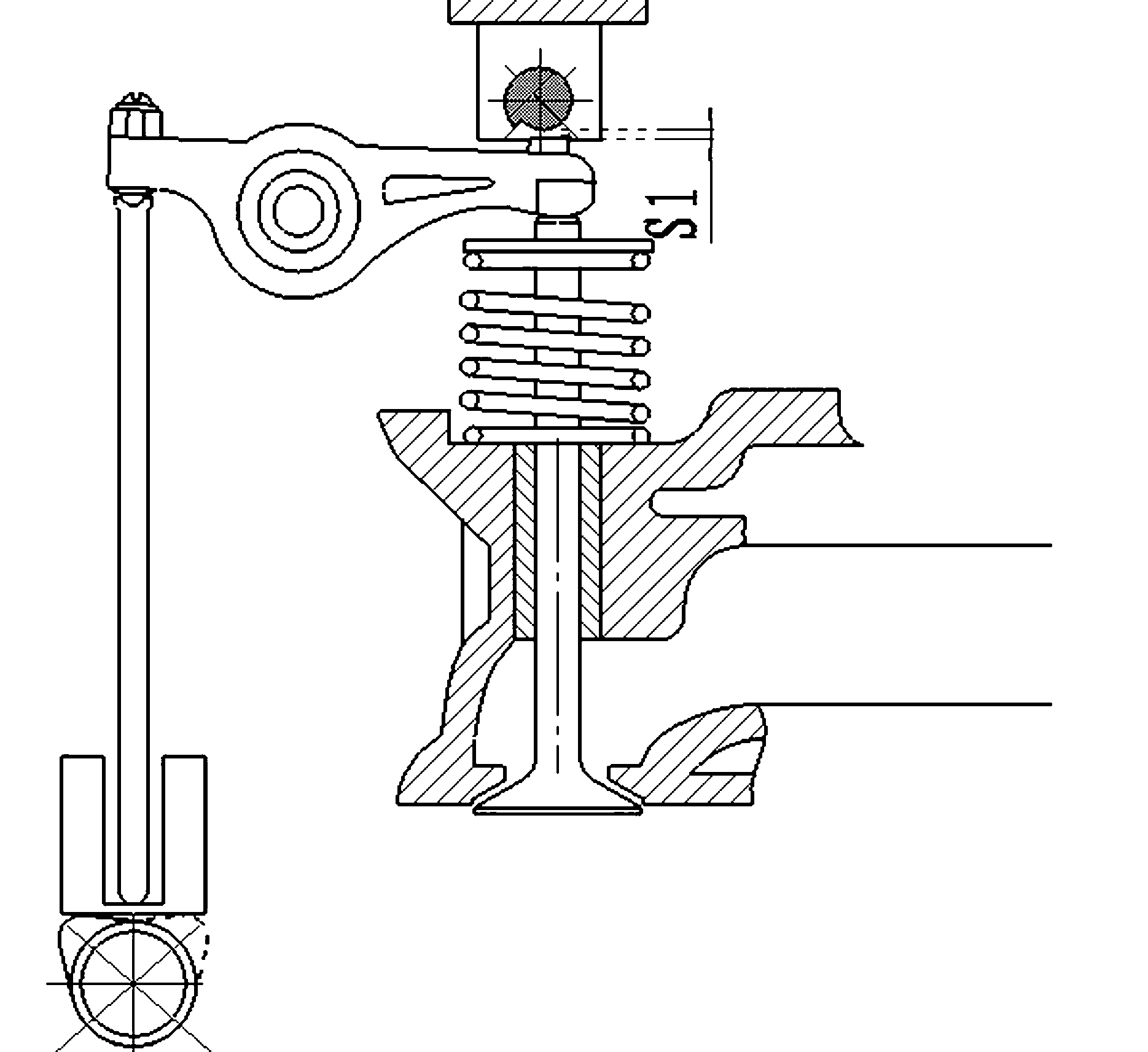

[0018] Attached below figure 1 to attach Figure 7 The present invention will be further described.

[0019] 1. As attached figure 1 The engine retarder shown includes a tappet 11, a cam 10 positioned below the tappet 11 for driving the tappet 11 to move up and down, a push rod vertically installed on the tappet 11, a conduit installed on the cylinder head, The valve 9 slidingly installed in the conduit and the valve rocker arm 2 rotatably installed through the rotating shaft 1, one end of the valve rocker arm 2 is rotatably connected to the top of the push rod, and the other end of the rocker arm 2 is located at the end of the valve 8 Directly above, the upper part of the valve 8 is equipped with a spring seat 6, the valve spring 7 is inserted on the valve 8 and its two ends are respectively clamped between the spring seat 6 and the guide tube, and a The depressing device of the swing arm 2 is pressed downwards at the same time. Above-mentioned depressing device comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com