A kind of retarding type water reducing agent for phosphorus construction gypsum and its preparation method

A technology of phosphorus gypsum and water reducing agent is applied in the field of retarding water reducing agent and its preparation, which can solve the problems of strength loss of gypsum products, solidification and hardening speed block, loss of fluidity, etc., and achieves low cost and enhanced electronegativity. good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for preparing retarded water reducer, the steps are as follows:

[0027] S1. Preparation of polycarboxylic acid-based mother liquor: S11. Polycarboxylic acid-based mother liquor is made of the following raw material components in mass percentage: 40% unsaturated polyoxyethylene ether, 8% unsaturated acid, 1% chain transfer agent, initiator 0.2%, alkali 0.8%, and the rest is water; S12, add unsaturated polyoxyethylene ether and water into the reaction kettle, stir until dissolved; after stirring evenly, heat up to 50-60°C, then add water and chain transfer agent in sequence , unsaturated acid and initiator, keep the temperature constant, after the feeding is complete, keep warm and continue to react for 2 to 3 hours, neutralize with alkali solution until the pH is 7 to 9, and obtain the mother liquor of polycarboxylate superplasticizer.

[0028] S2. Preparation of fiber nanospheres: S21. Add cellulose fibers to lye solution with a concentration of 2 ...

Embodiment 2

[0031] A retarder-type water reducer for phospho-building gypsum, which consists of the following components by weight: 95 parts of polycarboxylic acid-based mother liquor, 14 parts of borax, 0.4 parts of retarder, and 0.5 parts of hydroxypropyl methyl cellulose ether, 0.09 parts of cellulose nanospheres, 0.6 parts of polysiloxane and 95 parts of water.

[0032] The preparation method is the same as in Example 1, and the water reducer product B is obtained.

Embodiment 3

[0034] A retarding water reducer for phospho-building gypsum, which consists of the following components by weight: 100 parts of self-made melamine-based mother liquor, 16 parts of borax, 0.6 parts of retarder, and 0.3 parts of hydroxypropyl methyl cellulose ether, 0.15 parts of cellulose nanospheres, 0.8 parts of polysiloxane and 100 parts of water. The preparation method of cellulose nanospheres is the same as that in Example 1. Add borax, retarder, hydroxypropyl methylcellulose ether, polysiloxane, and cellulose nanospheres to the melamine-based mother liquor in sequence, and stir evenly to obtain the water reducer product C.

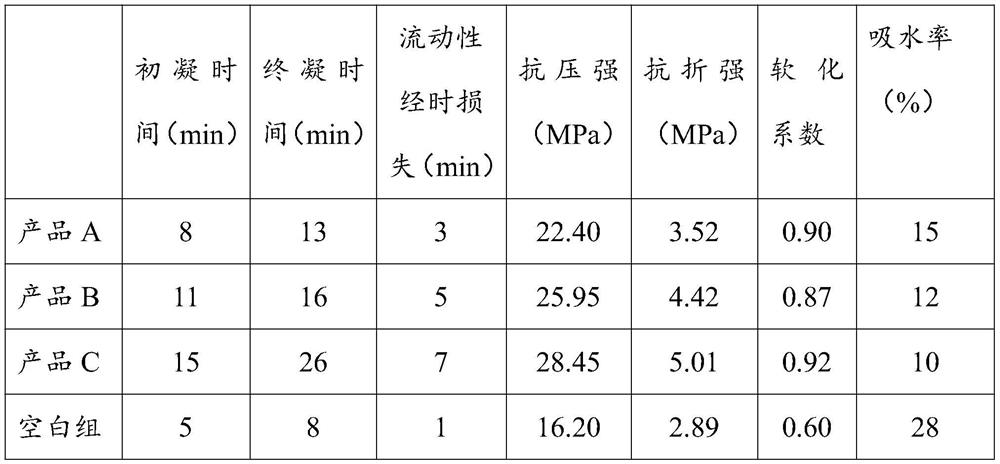

[0035] 2. Retarding time and strength test

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com