Electronic water pump for automobile

A technology for automotive electronics and water pumps, applied in pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of reduced pump efficiency and reliability, and achieve the effects of improving reliability, improving service life, and eliminating performance loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

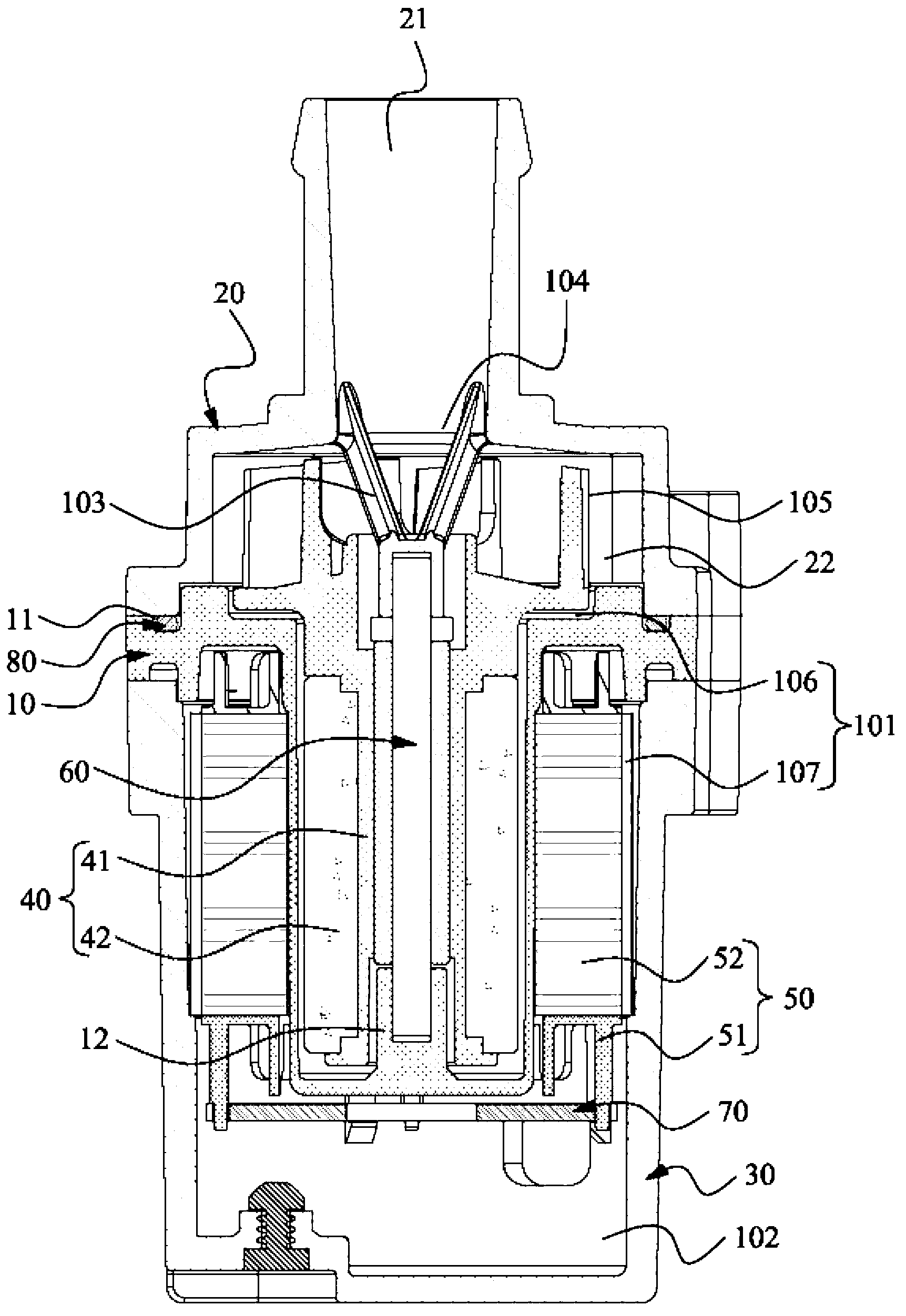

[0034] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a pump casing 10 , a pump head 20 , a casing 30 , a rotor 40 and a stator 50 .

[0035] The pump head 20 is installed on one end surface of the pump casing 10 and forms a pump cavity 101 surrounded by the pump casing 10. A shaft core 60 is fixed inside the pump cavity 101. The inner end of the shaft core 60 is fixedly connected with the pump casing 10. The pump head 20 is provided with a water inlet 21 and a water outlet 22 , the water inlet 21 and the water outlet 22 are connected to the pump chamber 101 , and the shaft core 60 is axially facing the water inlet 21 .

[0036] The casing 30 is installed on the other end surface of the pump casing 10 and forms a closed accommodating chamber 102 with the pump casing 10 .

[0037] The rotor 40 is located in the aforementioned pump cavity 101, one end of the rotor 40 is rotatably mounted on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com