Double-coating steel tube

A double-coated, steel pipe technology, applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of affecting the service life of steel pipes, reducing the corrosion resistance, and reducing the corrosion resistance of epoxy resin coated steel pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

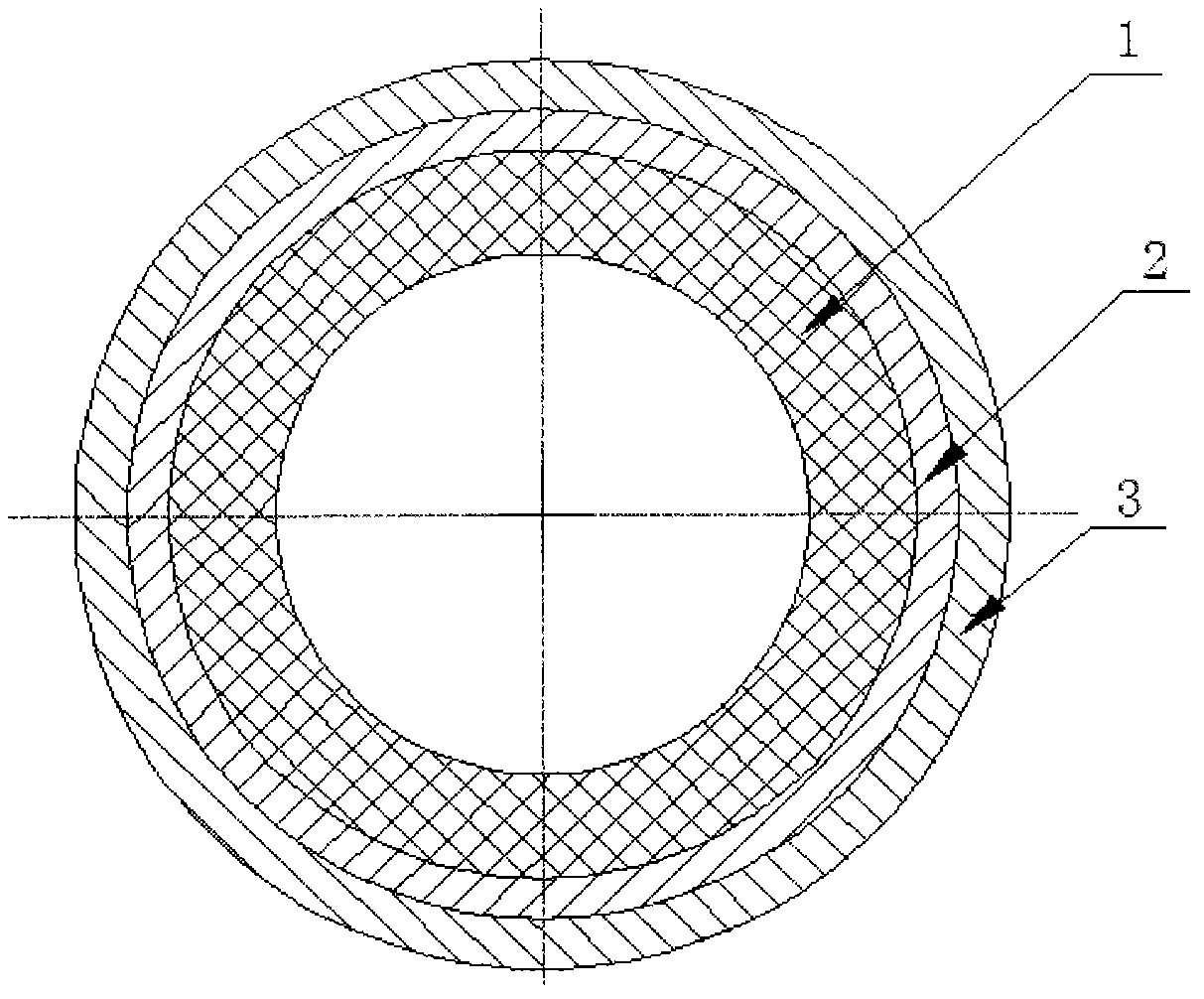

[0010] Double-coated steel pipe structure as attached figure 1 shown. The outer surface of the base steel pipe 1 is sequentially coated with the zinc layer 2 as the bottom layer and the epoxy coating 3 as the surface layer, and the steel pipe 1, the bottom layer zinc layer 2 and the surface layer epoxy coating 3 are respectively bonded together, Composed of zinc, epoxy double-coated steel pipe.

[0011] The processing method of the present invention is as follows: spray liquid metal zinc on the surface of a clean substrate steel pipe by thermal spraying method to form a bottom zinc layer with a thickness of 100-200 μm; spray epoxy powder coating after spraying the zinc layer, The thickness of the epoxy coating on the surface layer is 200-800 μm. The bottom zinc layer and the surface layer epoxy coating are bonded together to form a zinc and epoxy double coating, and the zinc and epoxy double coating together with the base steel pipe form a zinc and epoxy double coating steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com