Color film substrate, production method thereof and liquid crystal panel

A manufacturing method and color filter substrate technology, applied in the fields of instruments, nonlinear optics, optics, etc., can solve the problem of low spacer support area ratio, the inability to further increase the aperture ratio of the pixel area, and low transmittance of the pixel aperture ratio, etc. problem, to achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

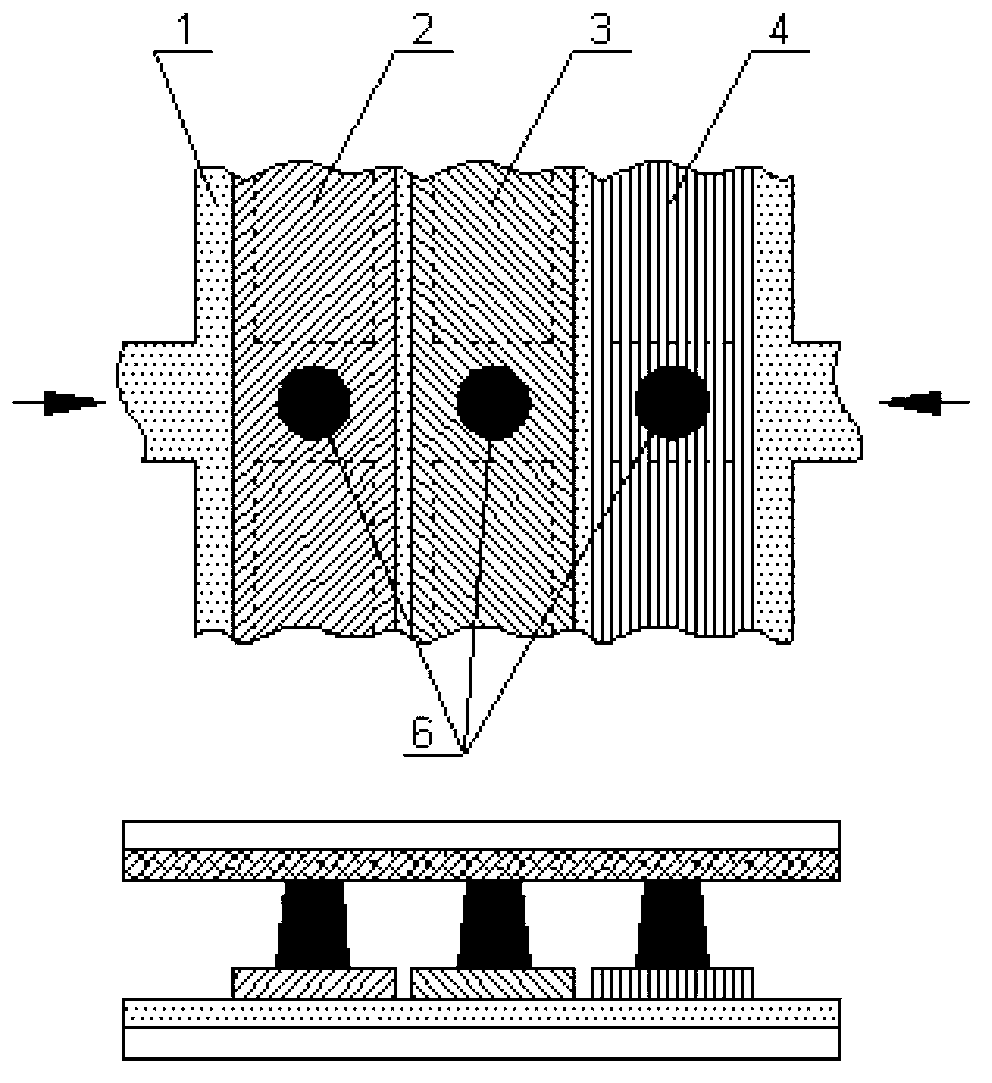

[0093] This embodiment provides a method for manufacturing a color filter substrate, including the following steps:

[0094] Step 1: setting a bottom pad at the designed position of the spacer on the first substrate;

[0095] Step 2: arranging spacers on the bottom pad and other designed positions of spacers without a bottom pad on the first substrate to form spacers with different heights; or, the bottom pad There are two or more different heights, and spacers are respectively arranged on the bottom pads of different heights to form spacers with different heights.

[0096] The color filter substrate includes a first substrate and a plurality of functional layers arranged on the first substrate.

[0097] Wherein, in step 1, the bottom pad can be directly or indirectly arranged on the first substrate. The so-called indirect installation means that the bottom pad is arranged on each functional layer on the first substrate without direct contact with the first substrate, such as...

Embodiment 2

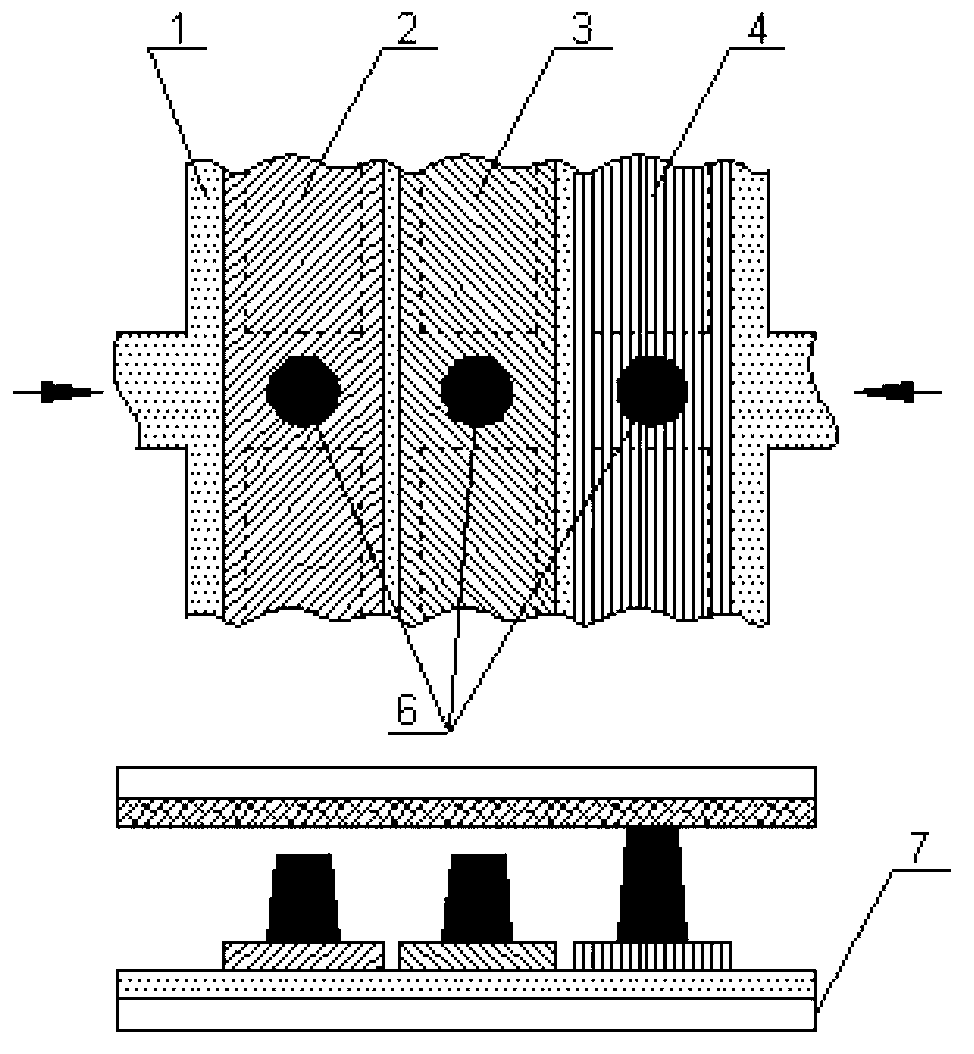

[0099] This embodiment provides a method for manufacturing a color filter substrate, including the following steps:

[0100] Step 1: setting the bottom pad 8 at the designed position of the spacer on the first substrate;

[0101] Step 2: setting spacers of the same height on the bottom pad and other designed positions of the spacers without bottom pads on the first substrate 7 to form spacers with different heights; or, The bottom pads have two or more different heights, and spacers of the same height are respectively arranged on the bottom pads of different heights to form spacers with different heights.

[0102] Since the manufacturing process of each functional layer (such as the black matrix) on the color filter substrate in this embodiment is the same as that of the prior art, it will not be described in detail here.

[0103] In step 1, setting the bottom pad at the designed position of the spacer on the first substrate specifically includes: forming the bottom pad 8 at ...

Embodiment 3

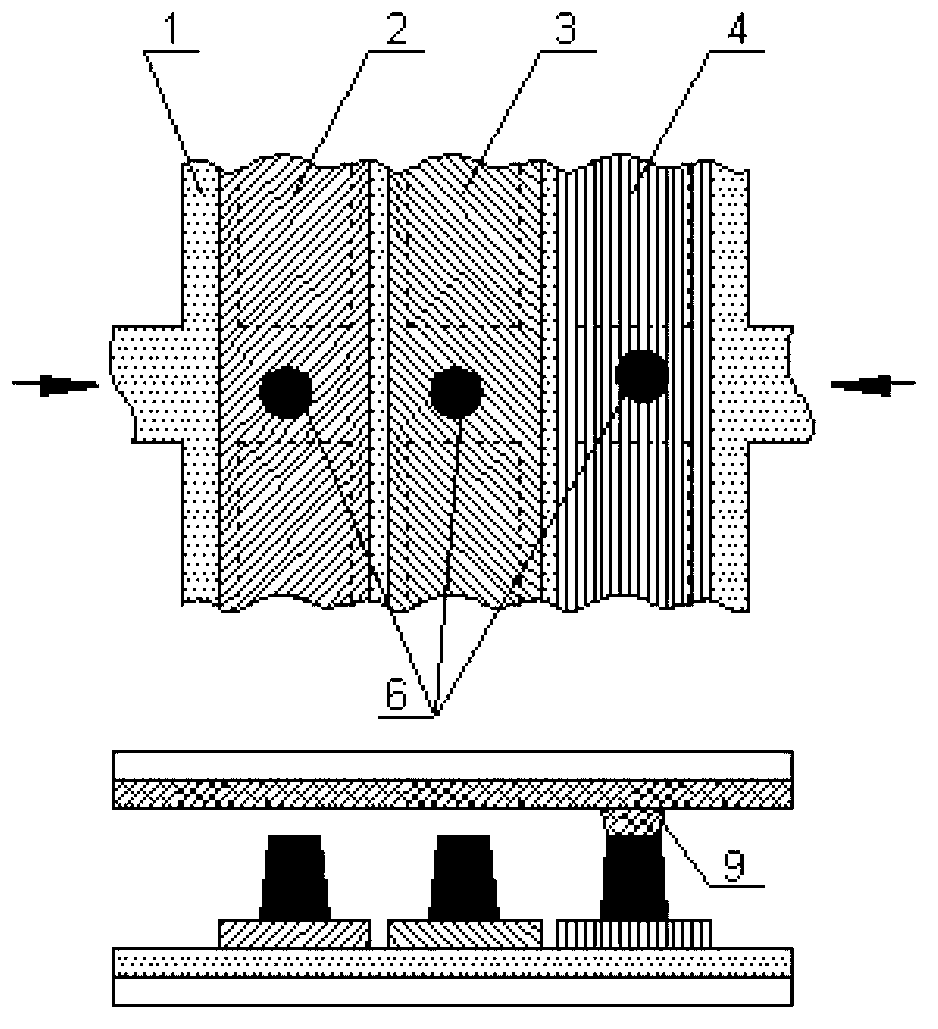

[0125] The difference between the manufacturing method of the color filter substrate in this embodiment and that in Embodiment 2 is that step 1 is slightly different.

[0126] In this embodiment, in step 1, the step of simultaneously forming the bottom pad during the process of forming the color film layer includes:

[0127] Step 11B: forming a first color film layer on the black matrix;

[0128] Step 12B: forming a second color film layer on the black matrix;

[0129] Step 13B: forming a third color film layer on the black matrix, and simultaneously forming a bottom pad on the first color film layer and the second color film layer. Wherein, the base pad and the third color film layer are simultaneously formed by the same mask plate through a patterning process, and the mask plate is formed by slightly improving the existing mask plate for making the color film layer.

[0130] Wherein, the bottom pad formed on the first color film layer and the bottom pad formed on the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com