Automatic focusing method of photoetching machine

An automatic focusing and lithography machine technology, applied in microlithography exposure equipment, optics, optical components, etc., can solve problems such as poor anti-interference ability and wrong focus, and achieve strong anti-interference ability, high precision, and calculation speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

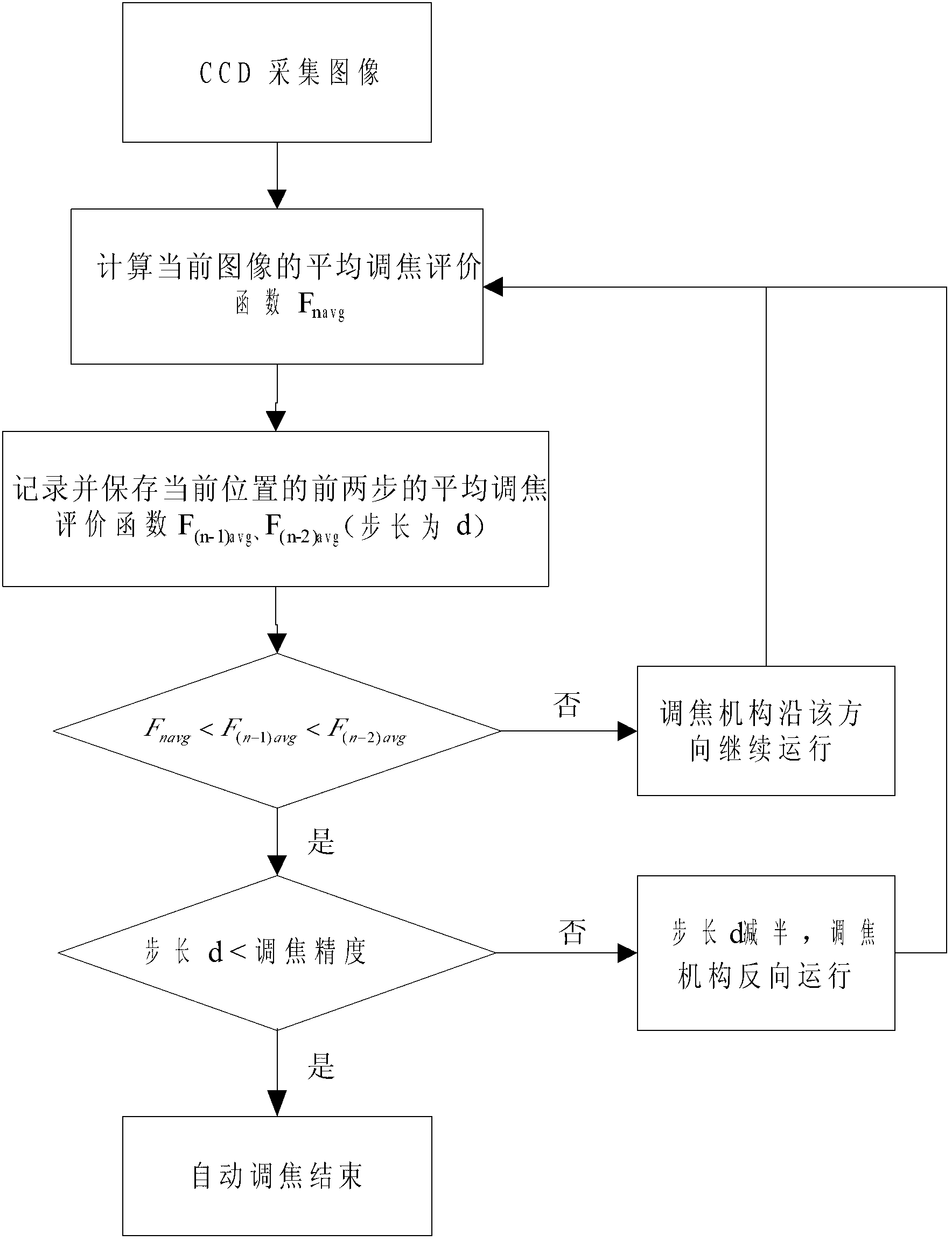

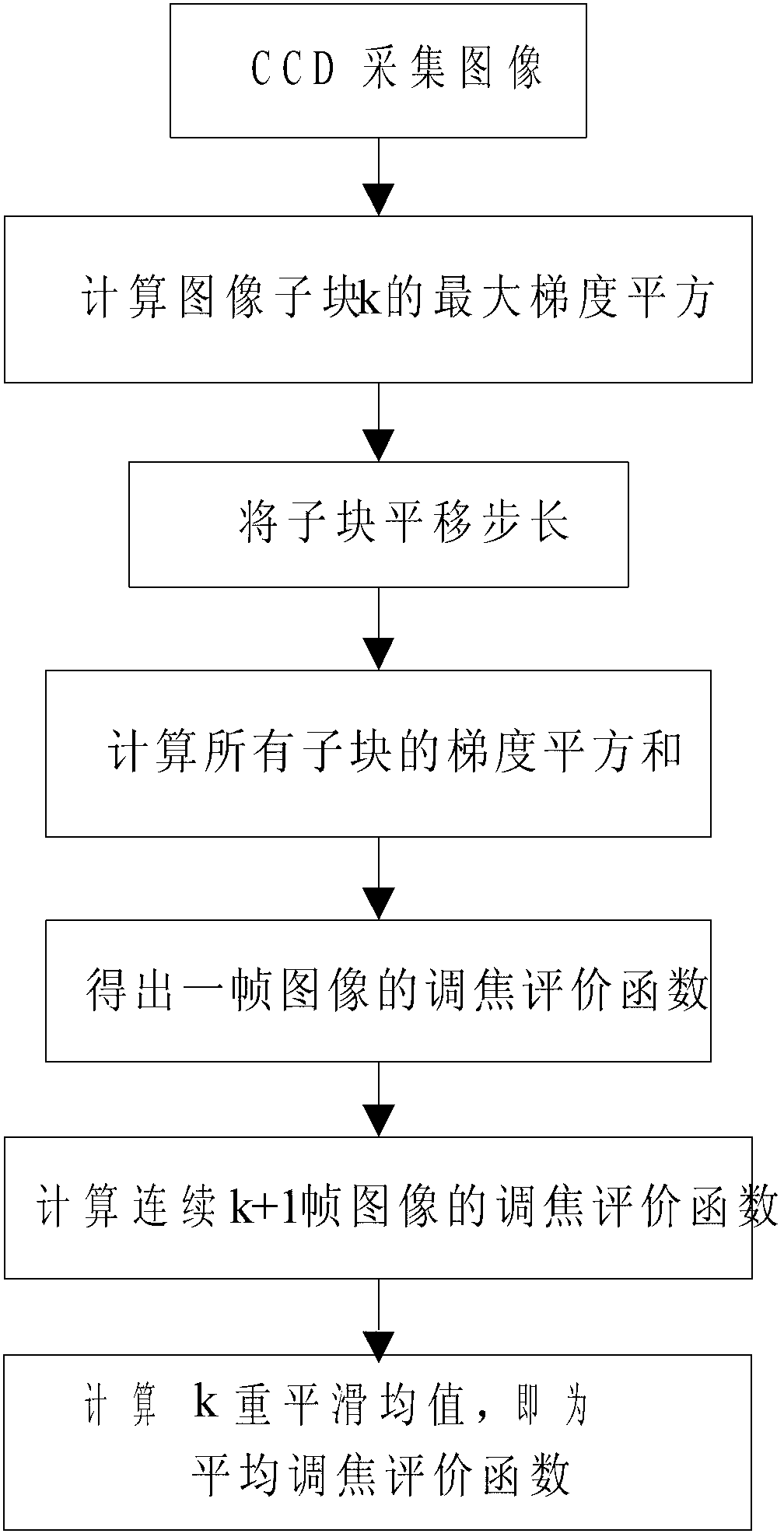

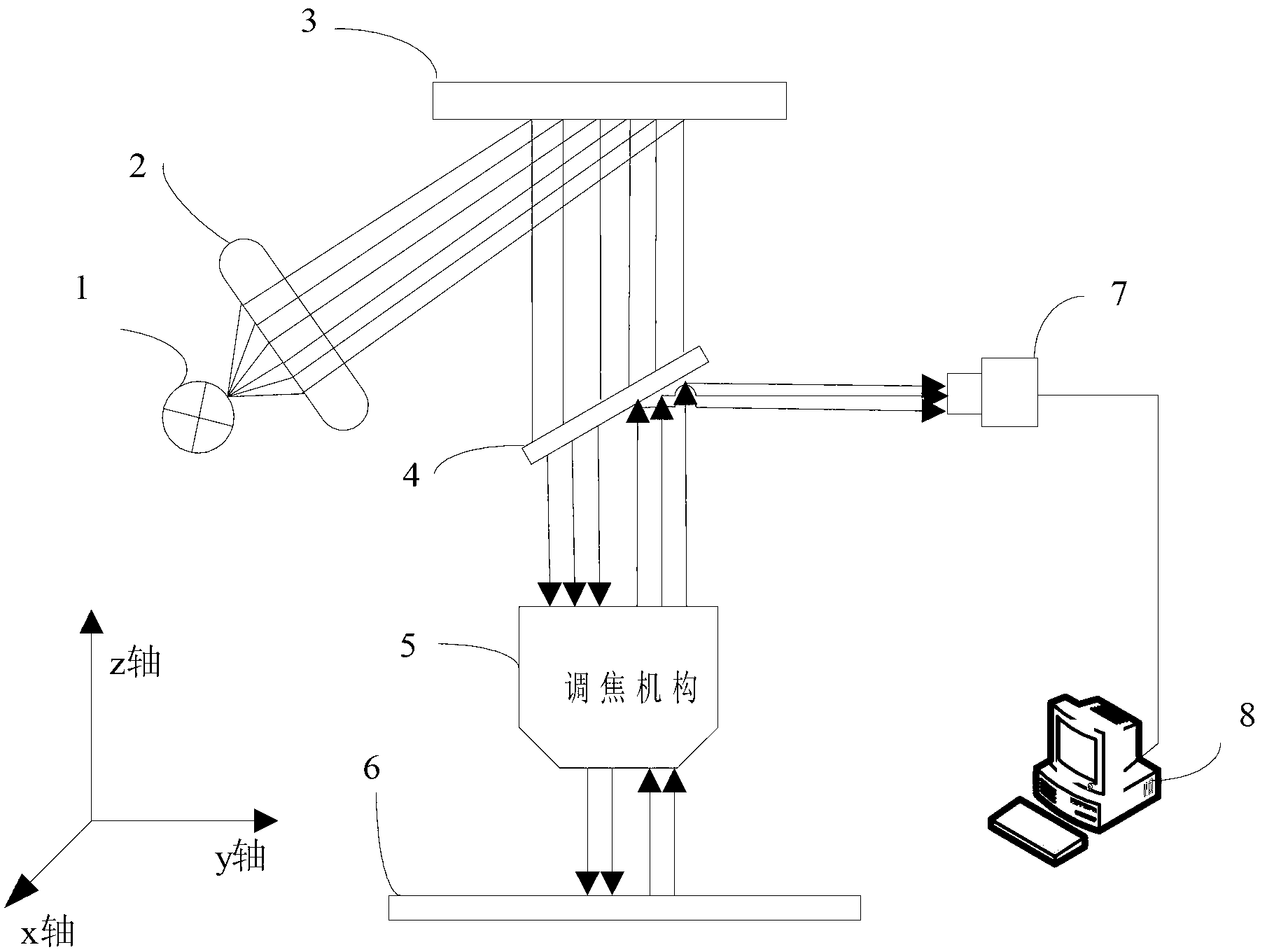

[0026] Specific implementation mode 1. Combination figure 1 and figure 2 To illustrate this embodiment, the automatic focusing method of a lithography machine described in this embodiment mainly includes two parts: the first part is the calculation method of the average focusing evaluation function of the image, and the second part is the automatic focusing mechanism of the focusing mechanism. The operation method, the specific steps are:

[0027] Step 1, the CCD camera collects image information, and transmits the collected image information to the computer;

[0028] Step 2. The computer receives the image information and calculates the average focusing evaluation function F of the image at the current position navg , the n is a positive integer, and n is greater than or equal to 2;

[0029] Step A. The computer divides the collected image into blocks, finds the maximum gray value and the minimum gray value in each sub-block, and obtains the maximum gradient square value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com