Device and method for debugging reflection point resistance of high stability oven controlled crystal oscillator

An oven-controlled crystal oscillator and crystal oscillator technology, applied in the direction of electrical components, automatic power control, etc., can solve the problems of cumbersome process, labor-intensive, poor data accuracy, etc., and achieve high production efficiency, simplified operation process, and accurate data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

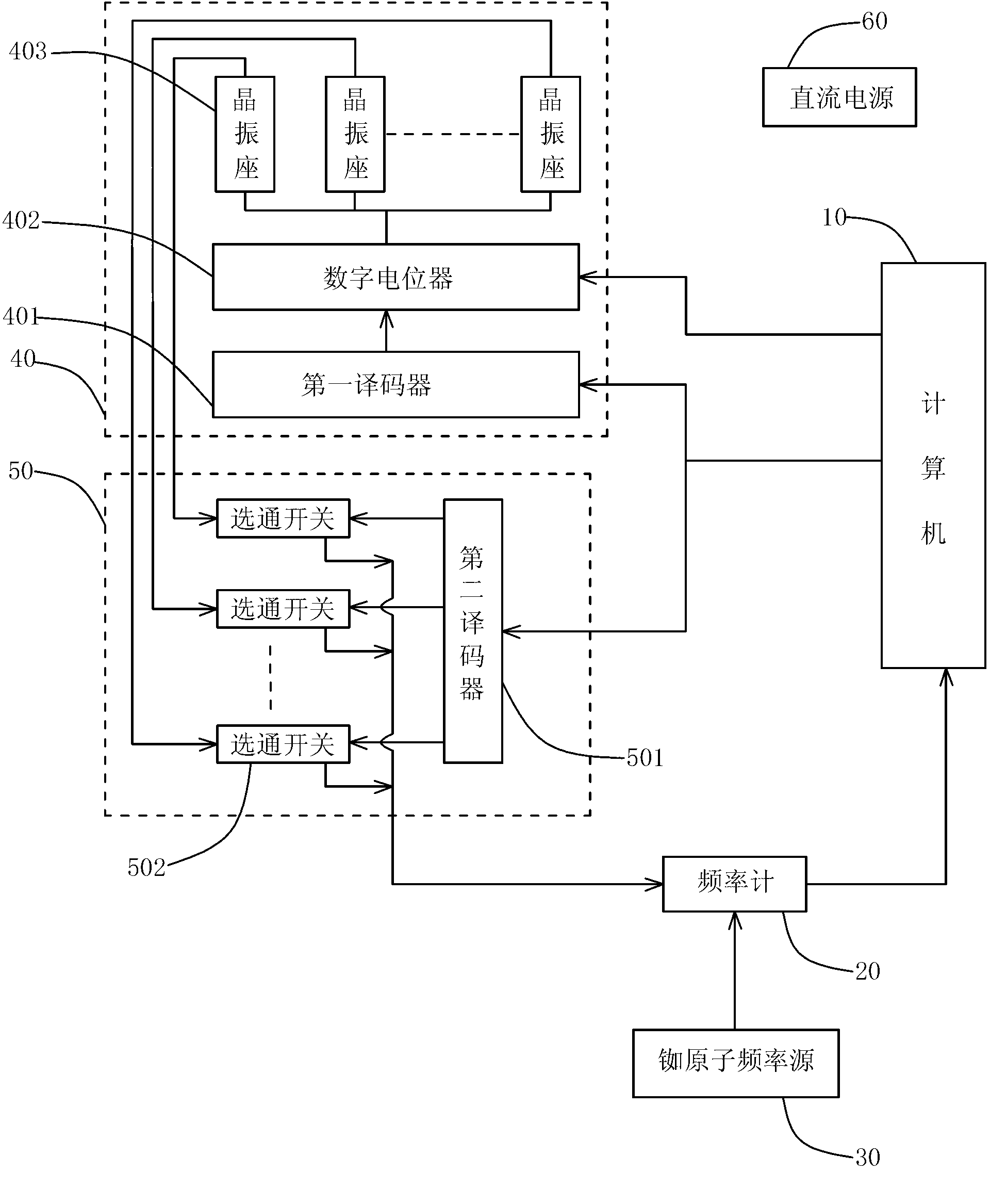

[0017] The invention discloses a high-stability constant temperature crystal oscillator inflection point resistance debugging device, such as figure 1 As shown, it includes a computer 10, a frequency meter 20, a rubidium atomic frequency source 30 and at least one layer of debugging rack, each layer of debugging rack is provided with a crystal oscillator debugging board 40 and a radio frequency control board 50, the crystal oscillator debugging board 40 and the radio frequency control board 50 each have a unique address code, wherein the rubidium atomic frequency source 30 sends an oscillating signal of a standard frequency to the standard frequency signal port of the frequency meter 20, and the frequency meter 20 uses the frequency of the oscillating signal as a reference frequency The crystal oscillator debugging board 40 includes a first decod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com